Welding device for bypass valves of lower end covers of filter elements of filters

A welding device and bypass valve technology, applied in auxiliary devices, welding equipment, welding equipment and other directions, can solve the problems of poor quality, low welding efficiency of filter bypass valve and lower end cover, etc., and achieve good product quality, The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

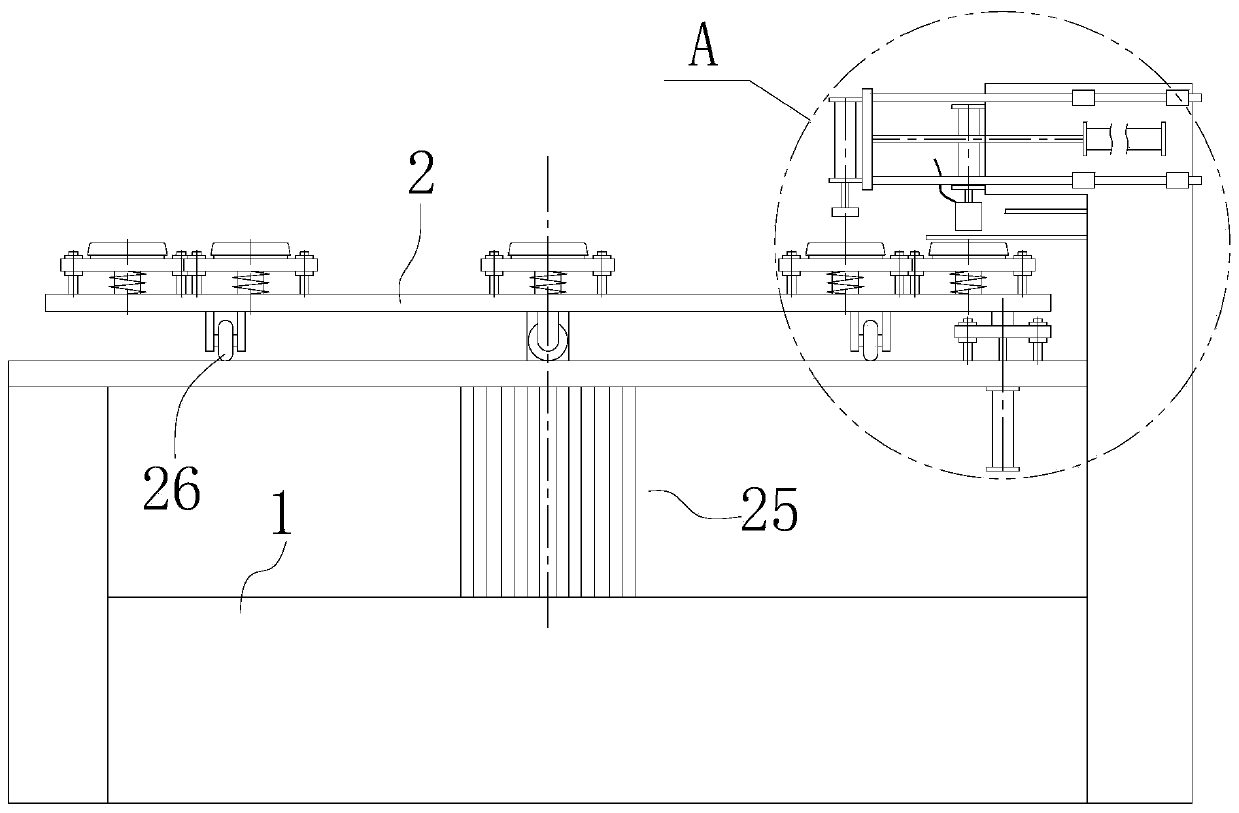

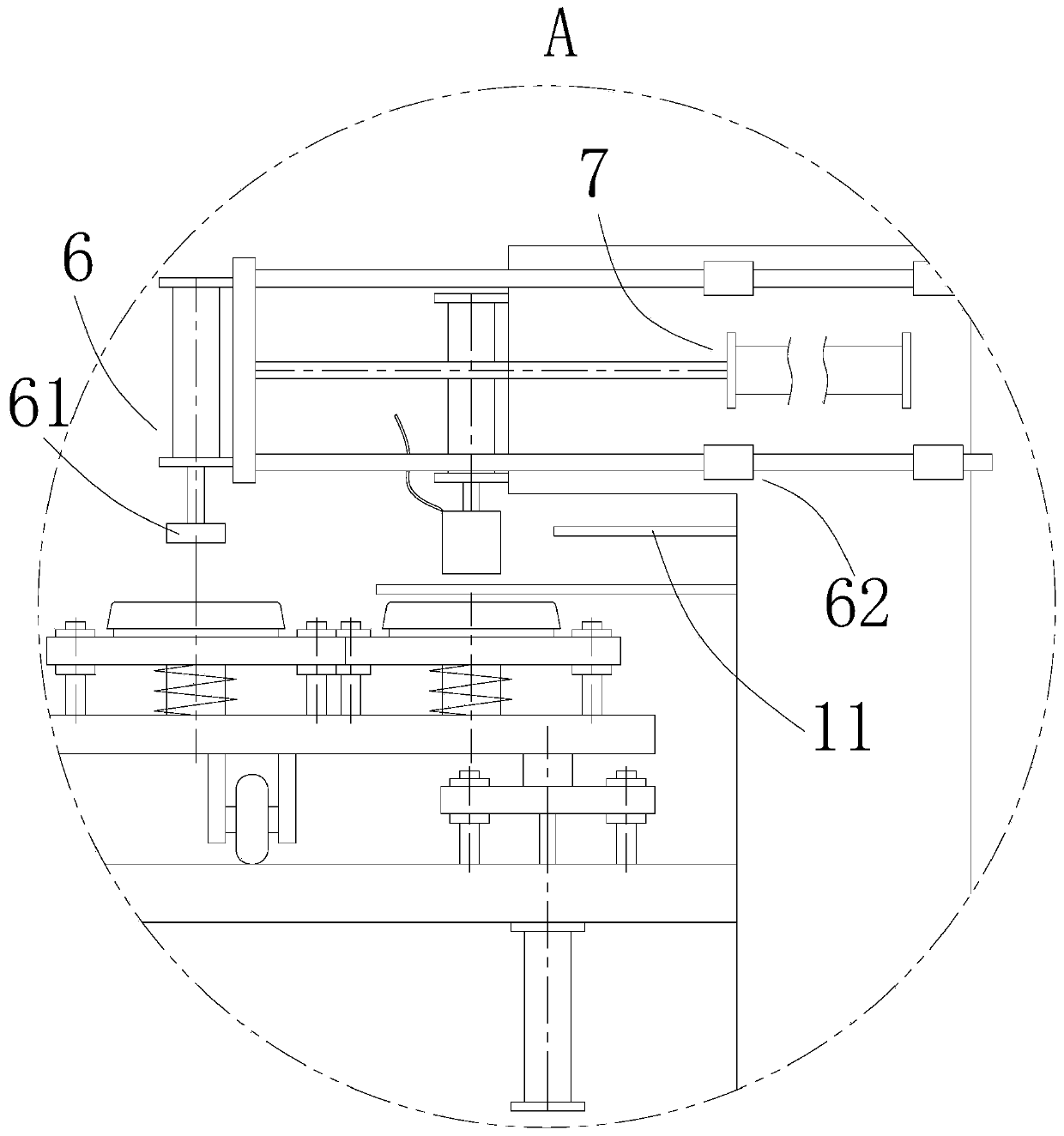

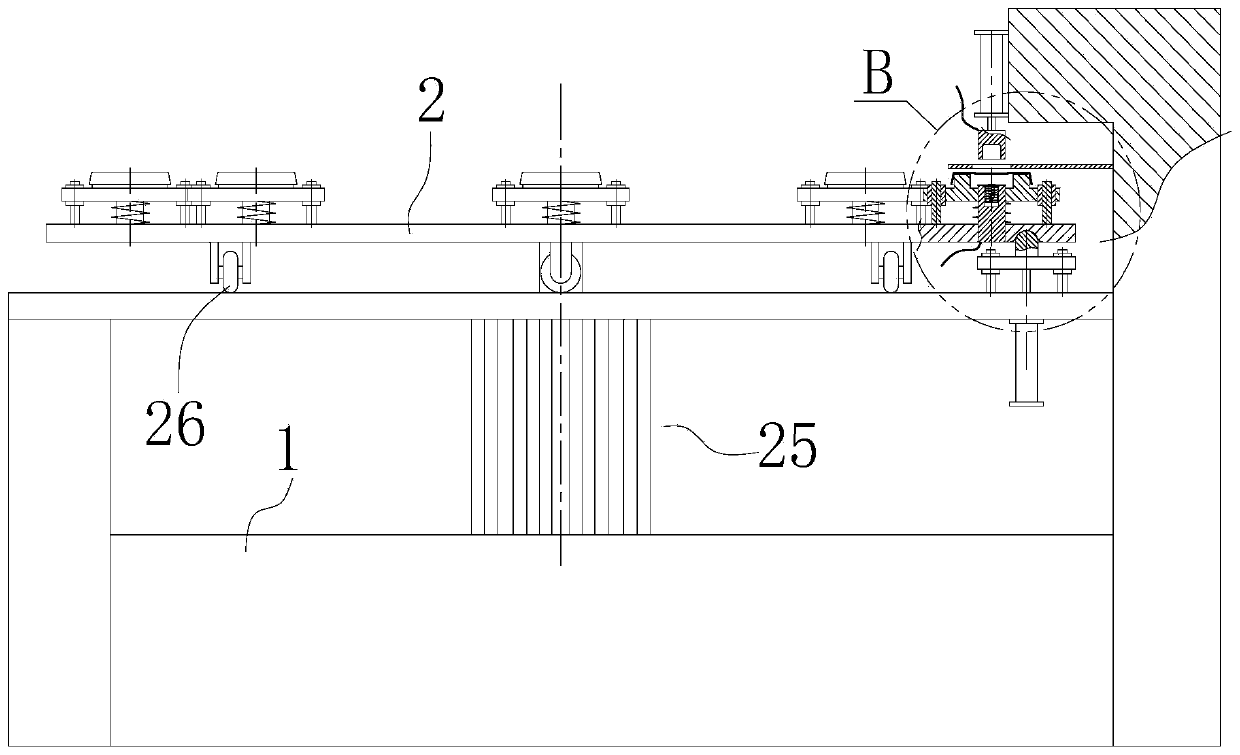

[0049] Such as Figure 1-4 As shown, a filter element lower end cover bypass valve welding device includes a frame 1, a turntable 2, a bypass valve 3, a lower end cover 4, a first lifting mechanism 5, a second lifting mechanism 6, and a lateral drive mechanism 7 ,control unit.

[0050] In this embodiment, the main function of the frame 1 is to provide installation positions for the rest of the components. The frame 1 is not limited to a specific shape, as long as it can meet the requirements of installing and matching each component, and realize the corresponding functions. , in order to avoid the frame 1 from covering the parts that need to be clearly shown, the shape of the frame 1 in the figure is not completely drawn.

[0051] The control unit in this embodiment adopts PLC, which is an existing technology, and those skilled in the art can program it according to actual needs to realize the control function described in this embodiment.

[0052] Such as figure 1 As shown...

Embodiment 2

[0061] The difference between this embodiment and Embodiment 1 is:

[0062] Such as Figure 4 As shown, the frame 1 is also provided with a turntable positioning mechanism 8 for limiting the rotation of the turntable 2. The turntable positioning mechanism 8 includes a positioning column 81 and a positioning column driving mechanism 82. matching positioning holes, and each column 21 corresponds to a positioning hole, the positioning column 81 is arranged on the movable end of the positioning column drive mechanism 82, when the turntable 2 drives the bypass valve 3 and the lower end cover 4 to a specific position, the positioning The column driving mechanism 82 drives the positioning column 81 to extend into the positioning hole to realize positioning. The positioning column driving mechanism 82 adopts a cylinder or a linear motor.

[0063] Such as Figure 4 As shown, it also includes a positioning plate 84 that is vertically slidably installed on the frame 1 through a third g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com