Micro-texture machining device for surface of metal plate

A technology for processing equipment and metal plates, applied in the field of microtexture processing equipment, can solve the problems of high cost and low processing efficiency, and achieve the effects of low processing cost, low equipment manufacturing cost, and improved load resistance capability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

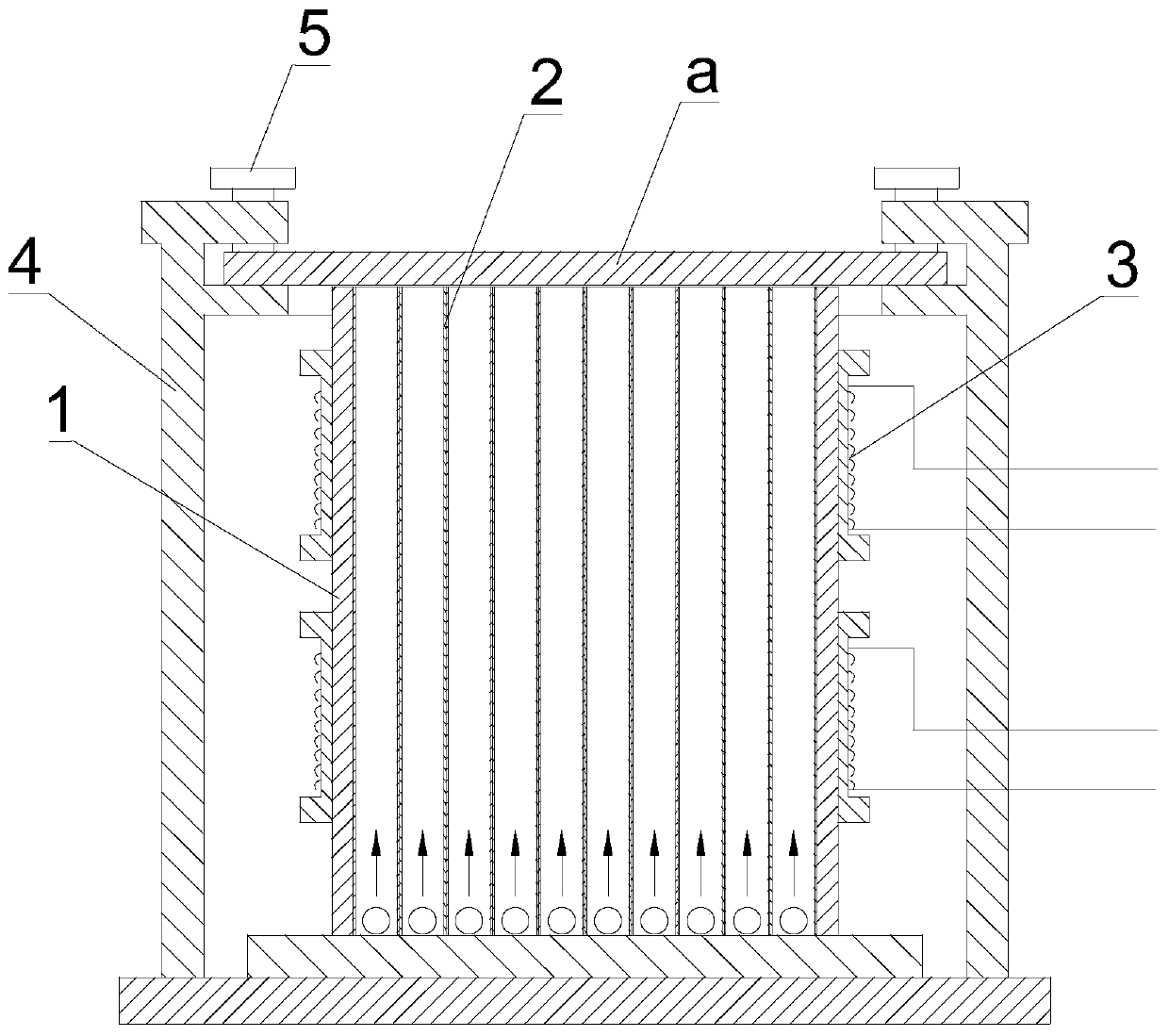

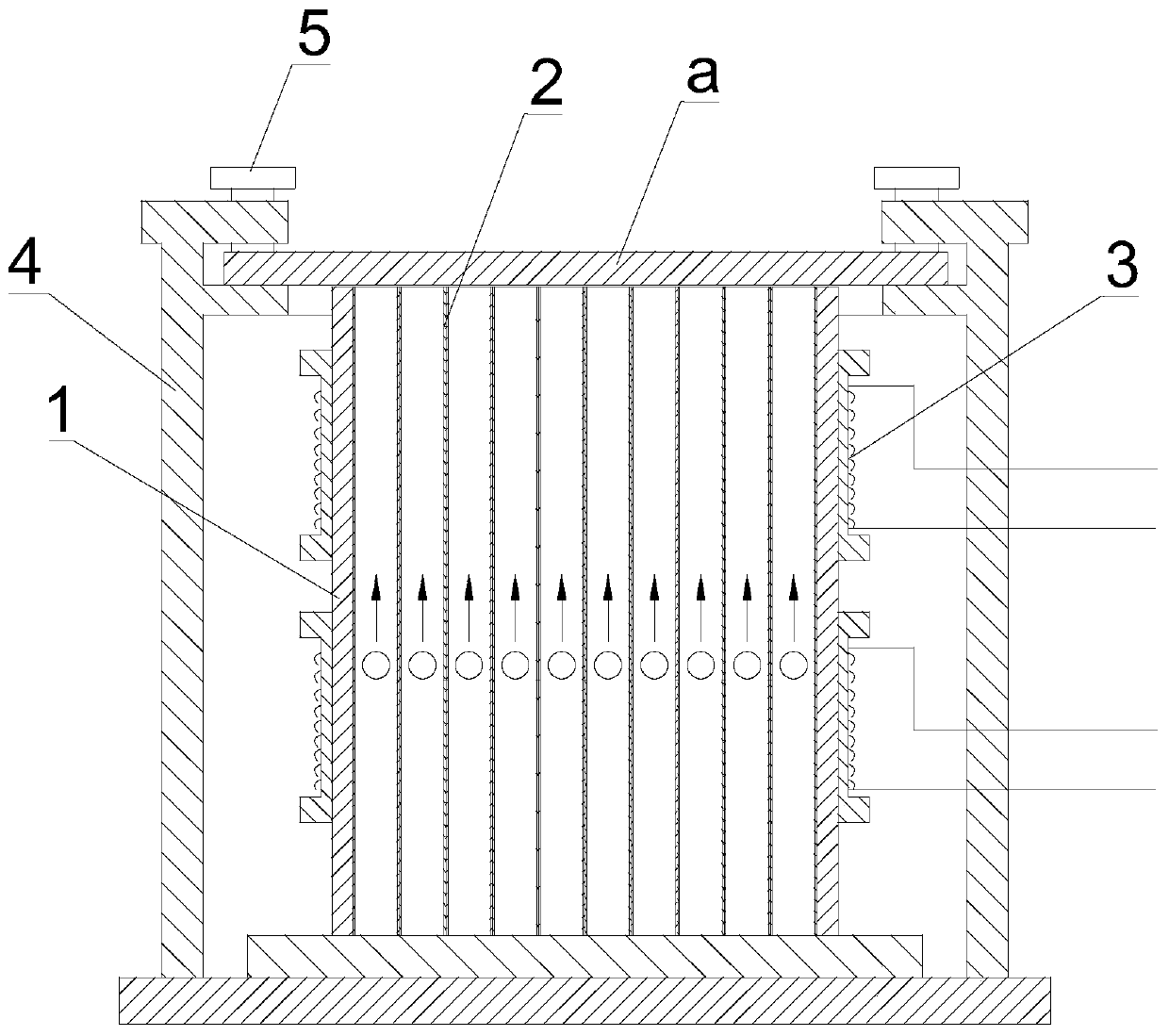

[0032] see Figure 1-4 , the micro-texture processing equipment for the surface of the metal plate in this embodiment includes a processing box 1, a clamping mechanism and an electromagnetic acceleration mechanism, wherein the processing box 1 is provided with a metal plate to be processed The inner cavity with the same shape as the processing plane of a (in this embodiment, the square metal plate a is taken as an example, of course it can be other shapes, such as elongated), the inner cavity is provided with a plurality of closely arranged straight Round pipe 2, the inner cavity of the straight round pipe 2 constitutes a processing channel, each processing channel is provided with steel balls for high-speed impact processing; the clamping mechanism clamps and fixes the metal plate a to be processed in the processing box The top of the body 1, the processing plane of the metal plate to be processed a is facing downwards and directly facing the multiple processing channels belo...

Embodiment 2

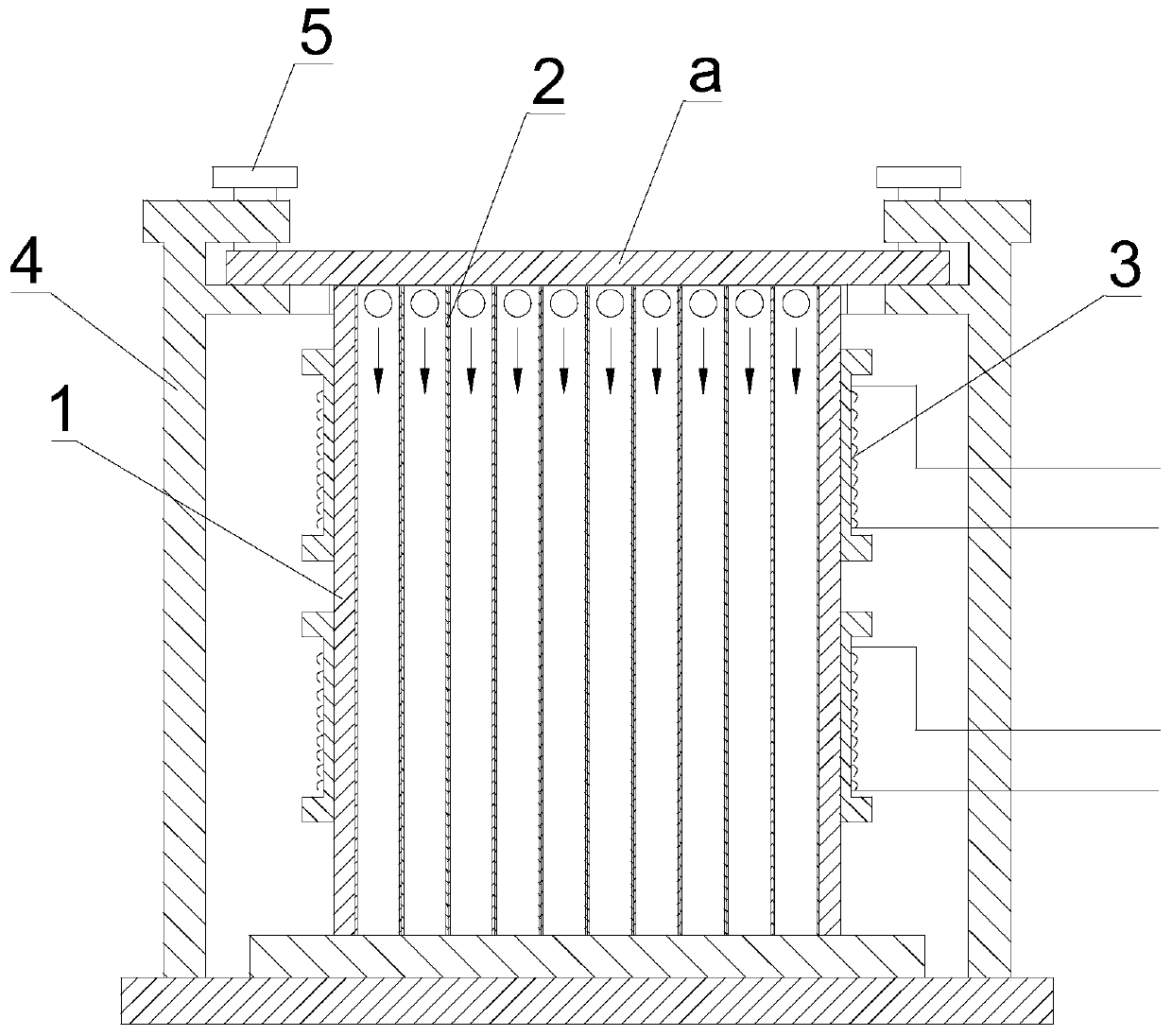

[0043] see Figure 5 , and the difference from Embodiment 1 is that there is one pulsed helical coil 3 in this embodiment, which is suitable for different processing occasions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com