Giant magnetostrictive flap wind turbine blade vibration reduction system and control method

A giant magnetostrictive, wind turbine blade technology, applied in the control of wind turbines, wind turbines, wind turbine components, etc., can solve the problems of limited, reduced total cost, and rising wind power total cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The preferred embodiments will be described in detail below in conjunction with the accompanying drawings. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

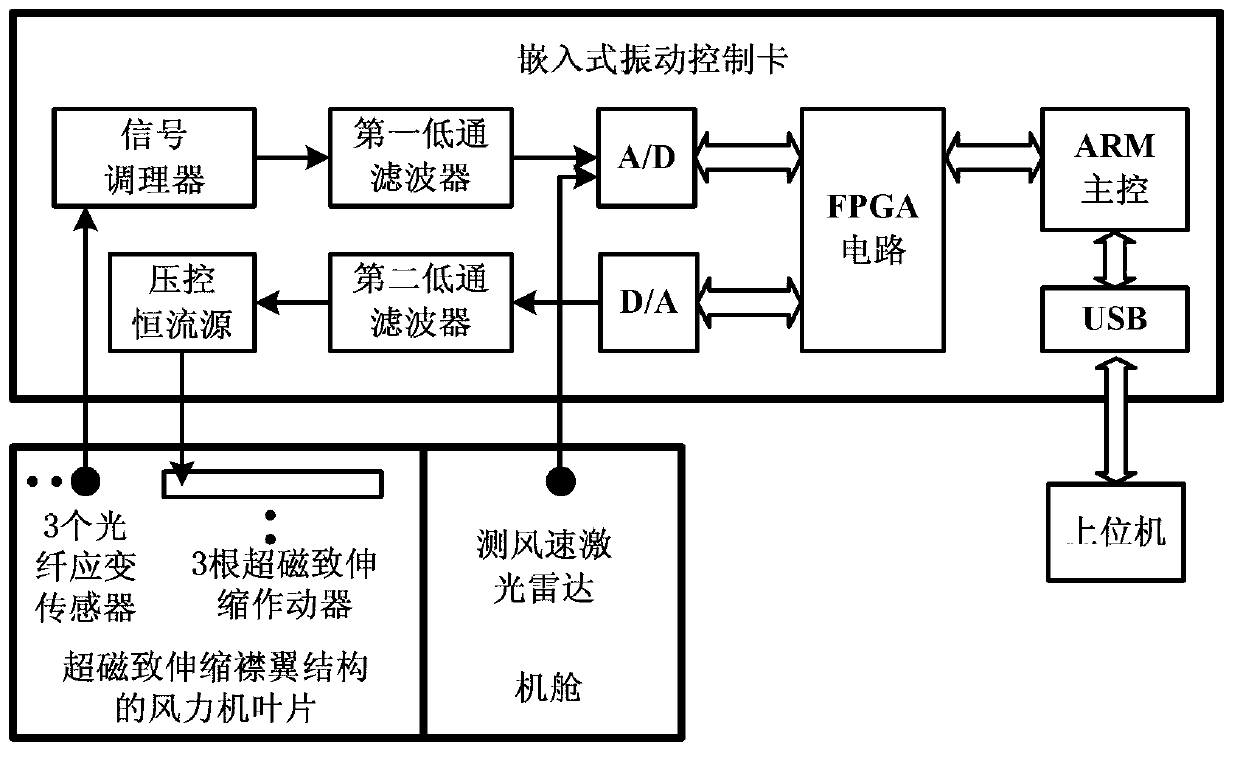

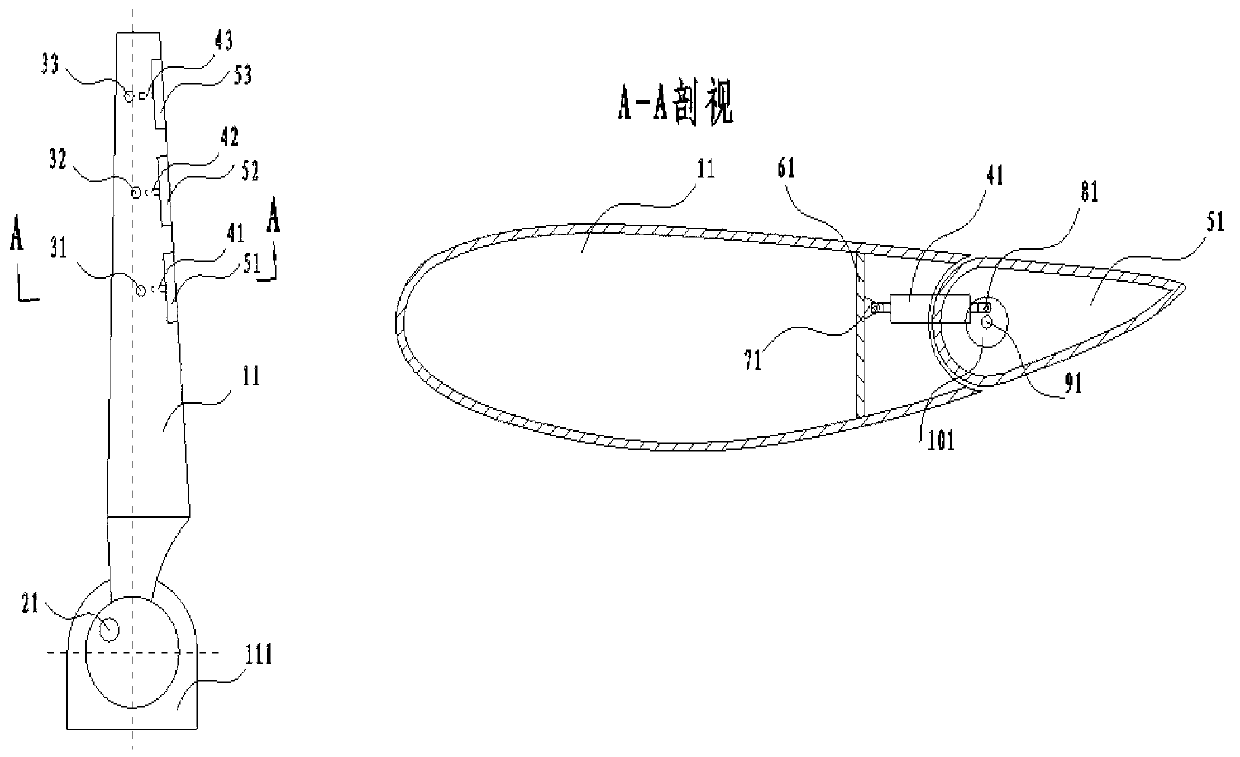

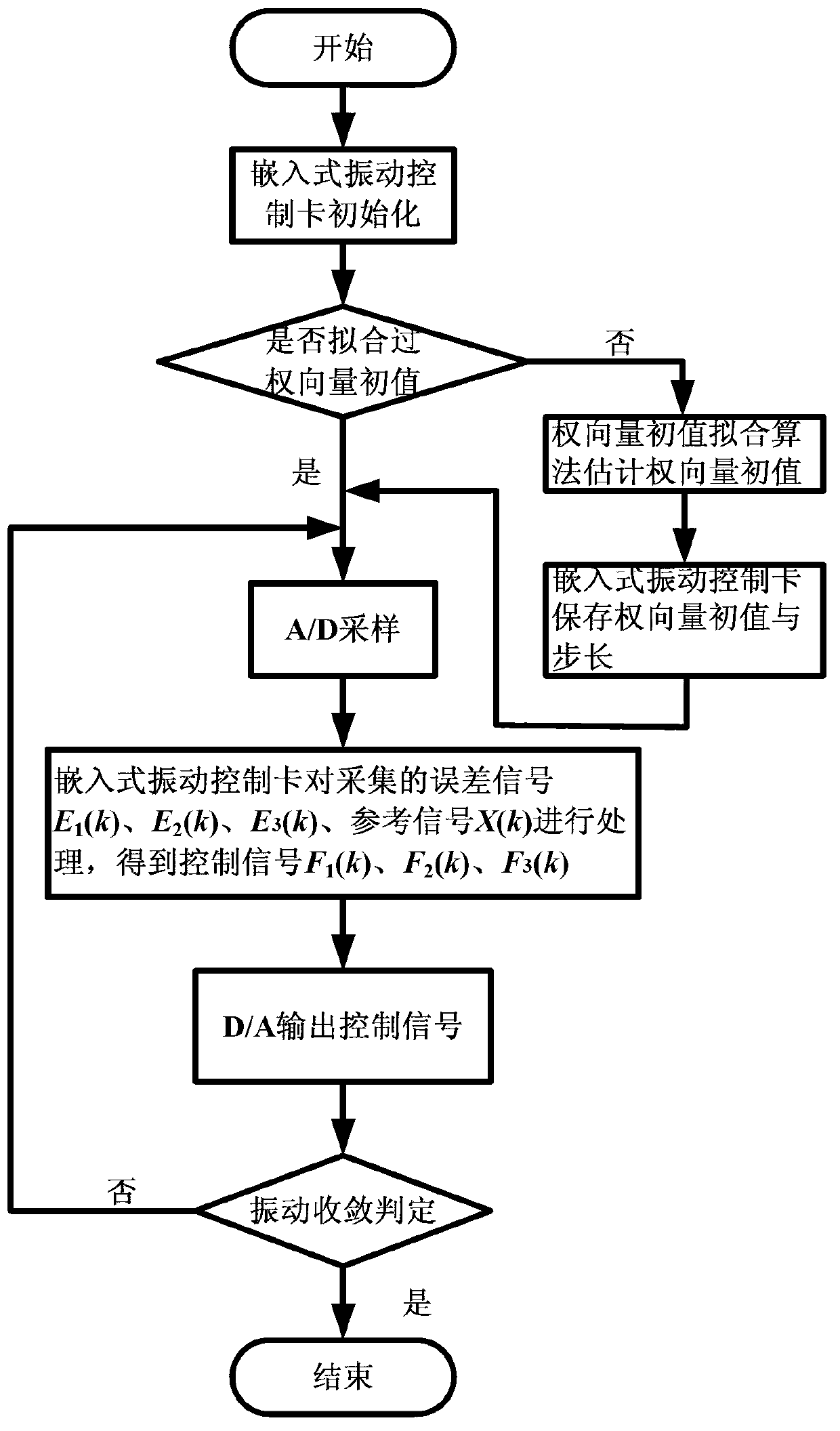

[0069] figure 1 It is a structural block diagram of a wind turbine blade damping system with a giant magnetostrictive flap structure provided by the present invention. figure 1 Among them, the system includes a wind turbine blade with a giant magnetostrictive flap structure, a wind speed laser radar, an embedded vibration control card and a host computer; the wind turbine blade with a giant magnetostrictive flap structure includes three optical fiber strain sensor and three giant magnetostrictive actuators; the embedded vibration control card includes an ARM main control chip, an FPGA circuit, an analog-to-digital converter, a first low-pass filter, a signal conditioner, a voltage-controlled constant current source, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com