High-temperature-resistant polytetrafluoroethylene lubricating grease for sealing and preparation method thereof

A technology for polytetrafluoroethylene grease and sealing, applied in lubricating compositions, petroleum industry, additives, etc., can solve problems such as poor high temperature resistance, achieve excellent extreme pressure and anti-wear performance, excellent lubricating performance, good The effect of tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

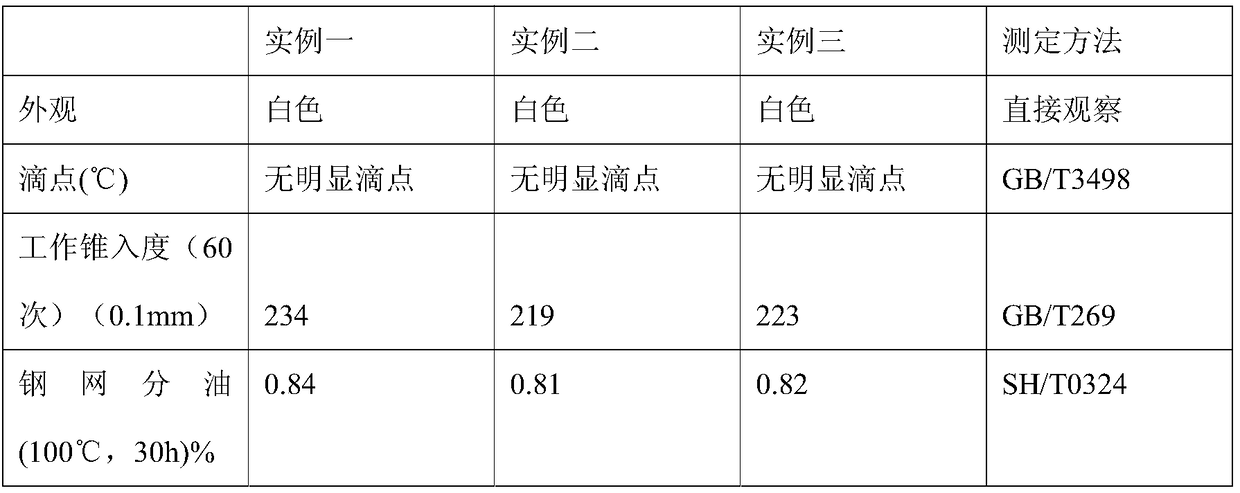

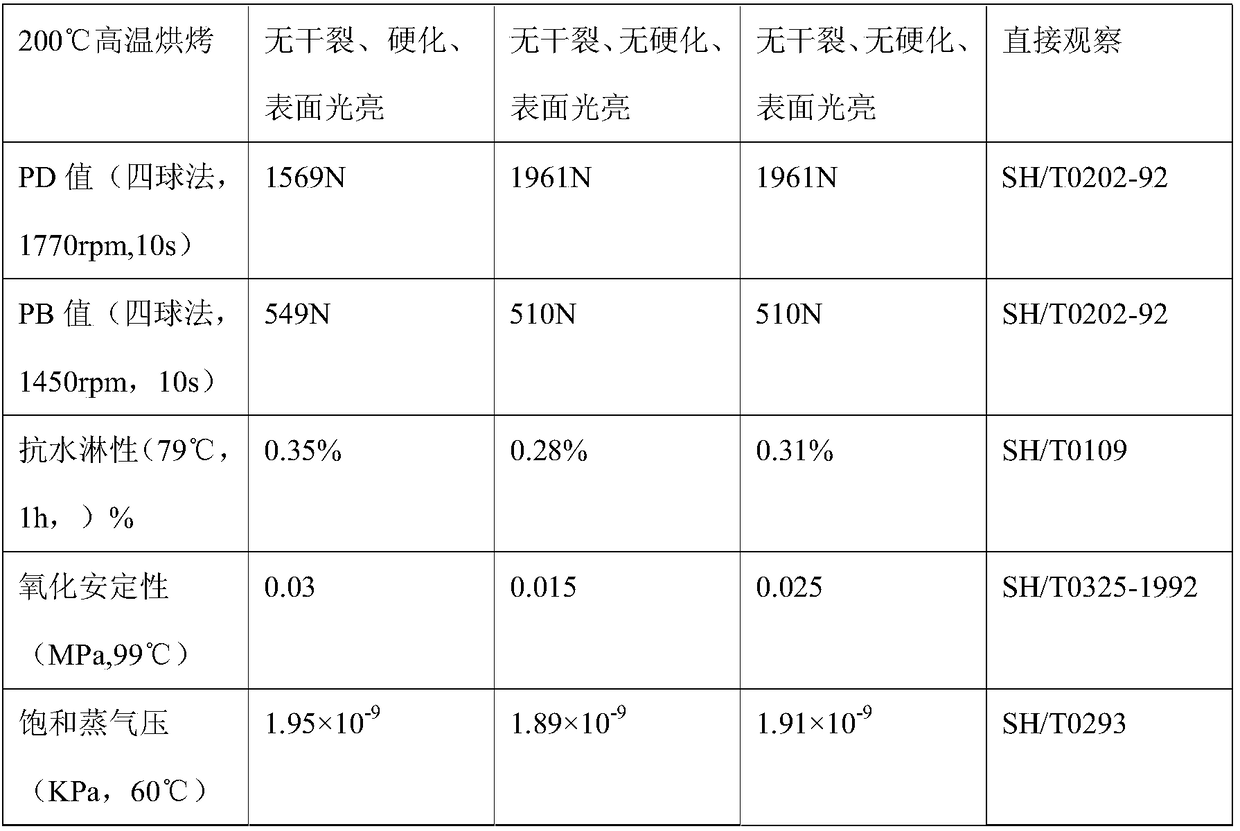

Examples

Embodiment 1

[0042] The following components are used to prepare the polytetrafluoroethylene grease for high temperature resistant sealing, based on the total mass of the grease, high viscosity methyl silicone oil: 15%, low viscosity methyl silicone oil: 25%, phenyl silicone oil: 15% , PTFE thickener: 30%, diphenylsilanediol: 3%, polymethyl methacrylate: 5%, boron nitride: 7%;

[0043] The preparation method of a kind of high-temperature-resistant sealing polytetrafluoroethylene grease product described in this example is as follows:

[0044] (1) Add base oil to the reactor and heat up to 120°C, and carry out stirring and heating reaction under this temperature condition;

[0045] (2) Add a structural stabilizer to the reactor and raise the temperature of the reactor to 150°C, and carry out a constant temperature stirring reaction for 20-30min;

[0046] (3) Add polytetrafluoroethylene powder to the reactor and carry out constant temperature refining and stirring reaction at 150°C for 1 ho...

Embodiment 2

[0052] The following components are used to prepare the polytetrafluoroethylene grease for high temperature resistant sealing, based on the total mass of the grease, high viscosity methyl silicone oil: 15%, low viscosity methyl silicone oil: 20%, phenyl silicone oil: 15% , PTFE thickener: 35%, diphenylsilanediol: 4%, polymethyl methacrylate: 6%, boron nitride: 4%, silicon dioxide: 1%;

[0053] The preparation method of a kind of high temperature resistant sealing polytetrafluoroethylene grease product described in this example is as follows:

[0054] (1) Add base oil to the reactor and heat up to 120°C, and carry out stirring and heating reaction under this temperature condition;

[0055] (2) Add a structural stabilizer to the reactor and raise the temperature of the reactor to 150°C, and carry out a constant temperature stirring reaction for 20-30min;

[0056] (3) Add polytetrafluoroethylene powder to the reaction kettle and carry out constant temperature refining and stirring...

Embodiment 3

[0062] The following components are used to prepare the polytetrafluoroethylene grease for high temperature resistant sealing, based on the total mass of the grease, high viscosity methyl silicone oil: 10%, low viscosity methyl silicone oil: 15%, phenyl silicone oil: 25% , PTFE thickener: 35%, structure stabilizer: 5%, polymethyl methacrylate: 5%, boron nitride: 3.5%, silicon dioxide 1.5%;

[0063] The preparation method of a kind of high-temperature-resistant sealing polytetrafluoroethylene grease product described in this example is as follows:

[0064] (1) Add base oil to the reactor and heat up to 120°C, and carry out stirring and heating reaction under this temperature condition;

[0065] (2) Add a structural stabilizer to the reactor and raise the temperature of the reactor to 150°C, and carry out a constant temperature stirring reaction for 20-30min;

[0066] (3) Add polytetrafluoroethylene powder to the reaction kettle and carry out constant temperature refining and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com