Infusion soft bag discharging device and method

A soft infusion bag and a technology for soft bags are applied in the field of infusion soft bag outlet devices, which can solve the problems of uneven bag outlet, affecting product sterilization quality, destroying leakage of welding surfaces, etc., so as to improve work efficiency and reduce The effect of manual intervention to improve product quality and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

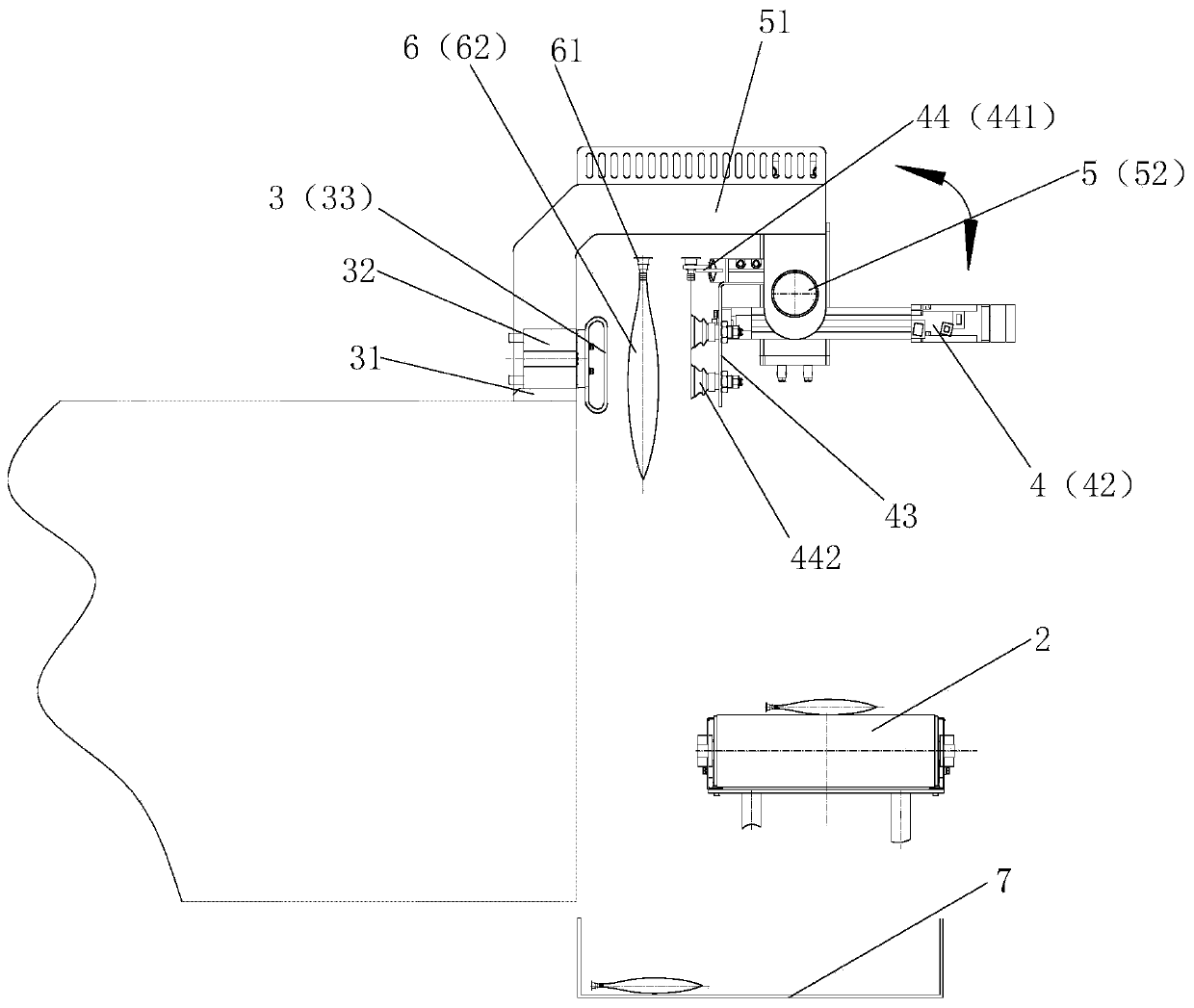

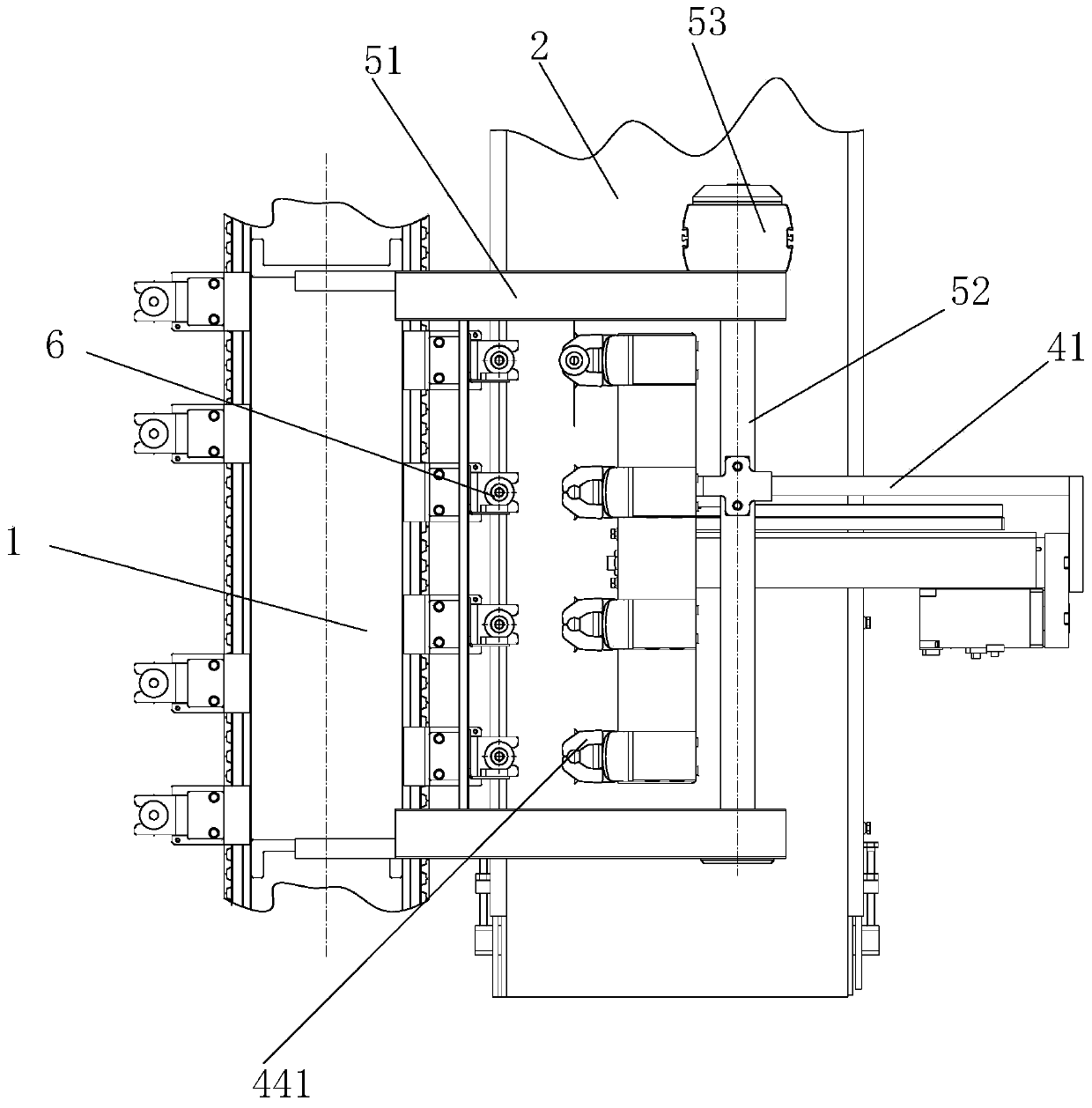

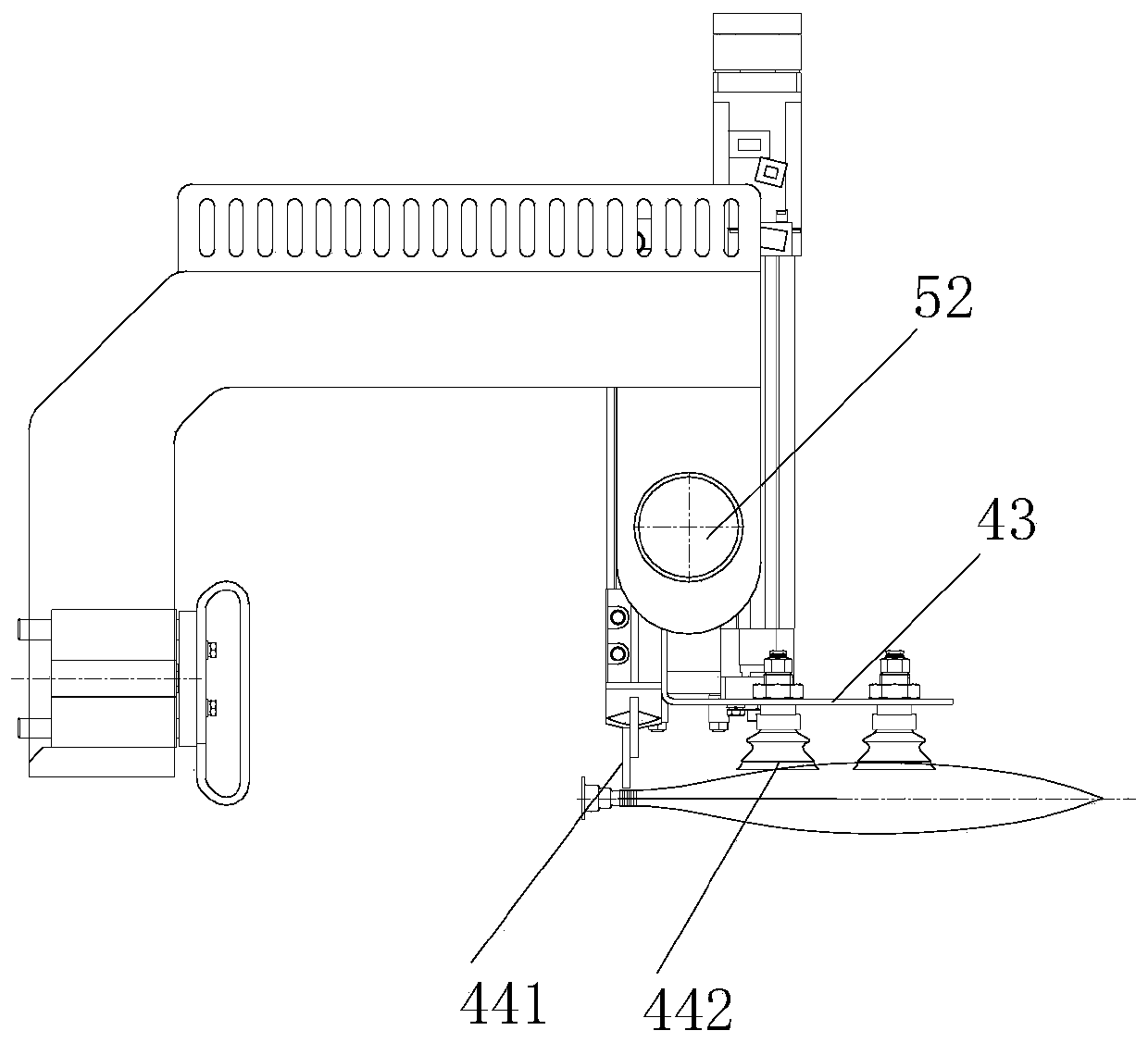

[0028] Figure 1 to Figure 3 An embodiment of the present invention is shown. The bag-out device for infusion soft bags of this embodiment includes a soft bag conveying mechanism 1, a soft bag output mechanism 2, and a flexible bag telescopic clamping mechanism 4 and a rotating mechanism 5. The bag telescopic clamping mechanism 4 is arranged on the side of the soft bag conveying mechanism 1, the soft bag output mechanism 2 is arranged below the soft bag telescopic clamping mechanism 4, and the rotating mechanism 5 is connected with the soft bag telescopic clamping mechanism 4. Wherein, the soft bag conveying mechanism 1 can be a common conveyer belt and is uniformly provided with clamping jaws 441 along the length direction to clamp the mouth pipe 61 of the soft bag 6 in a vertical state for conveying; the soft bag output mechanism 2 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap