Method for operating textile machine and textile machine

A textile machine and control mechanism technology, applied to spinning machines, textiles and papermaking, open-end spinning machines, etc., can solve the problems of high cost and achieve the effect of quick start

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

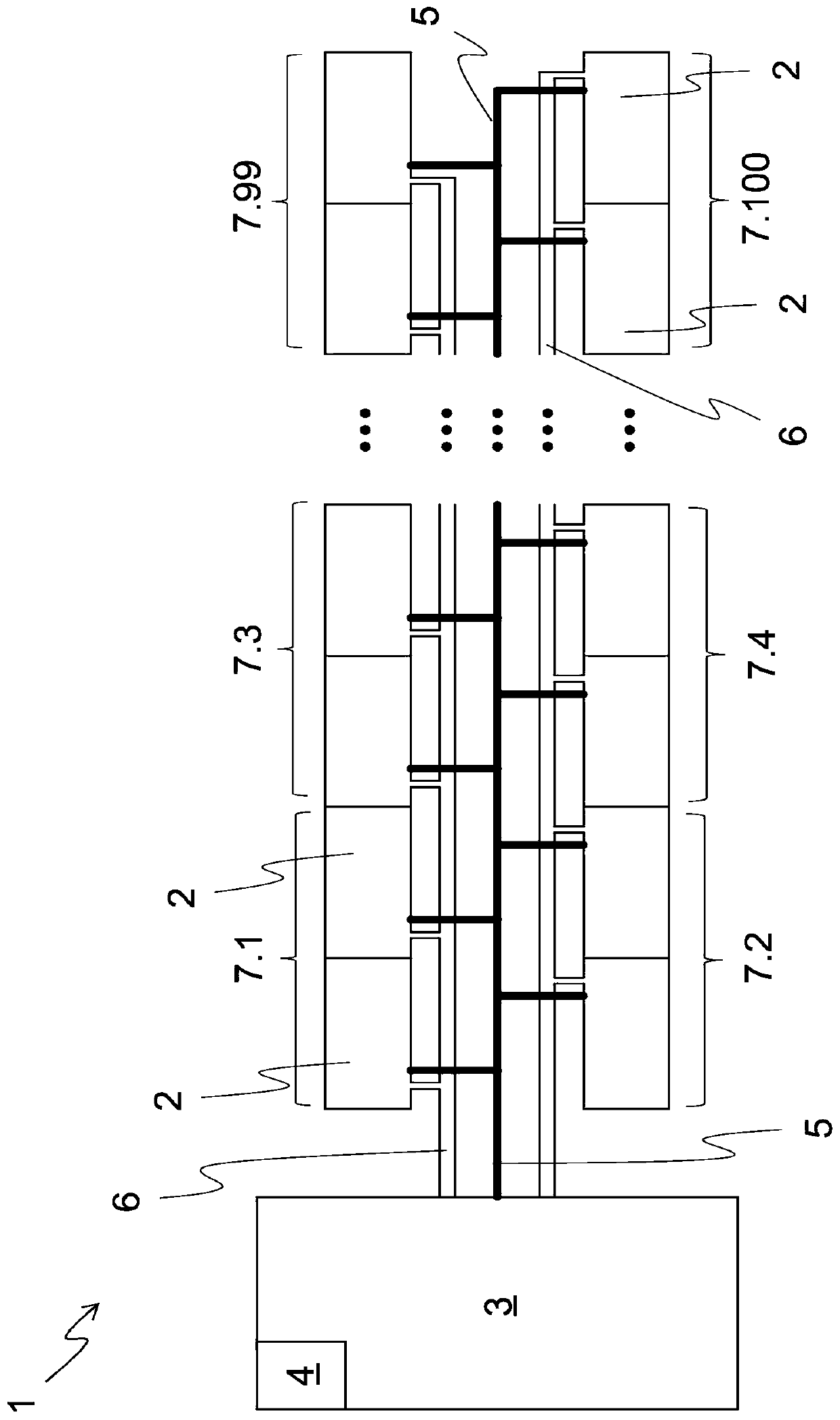

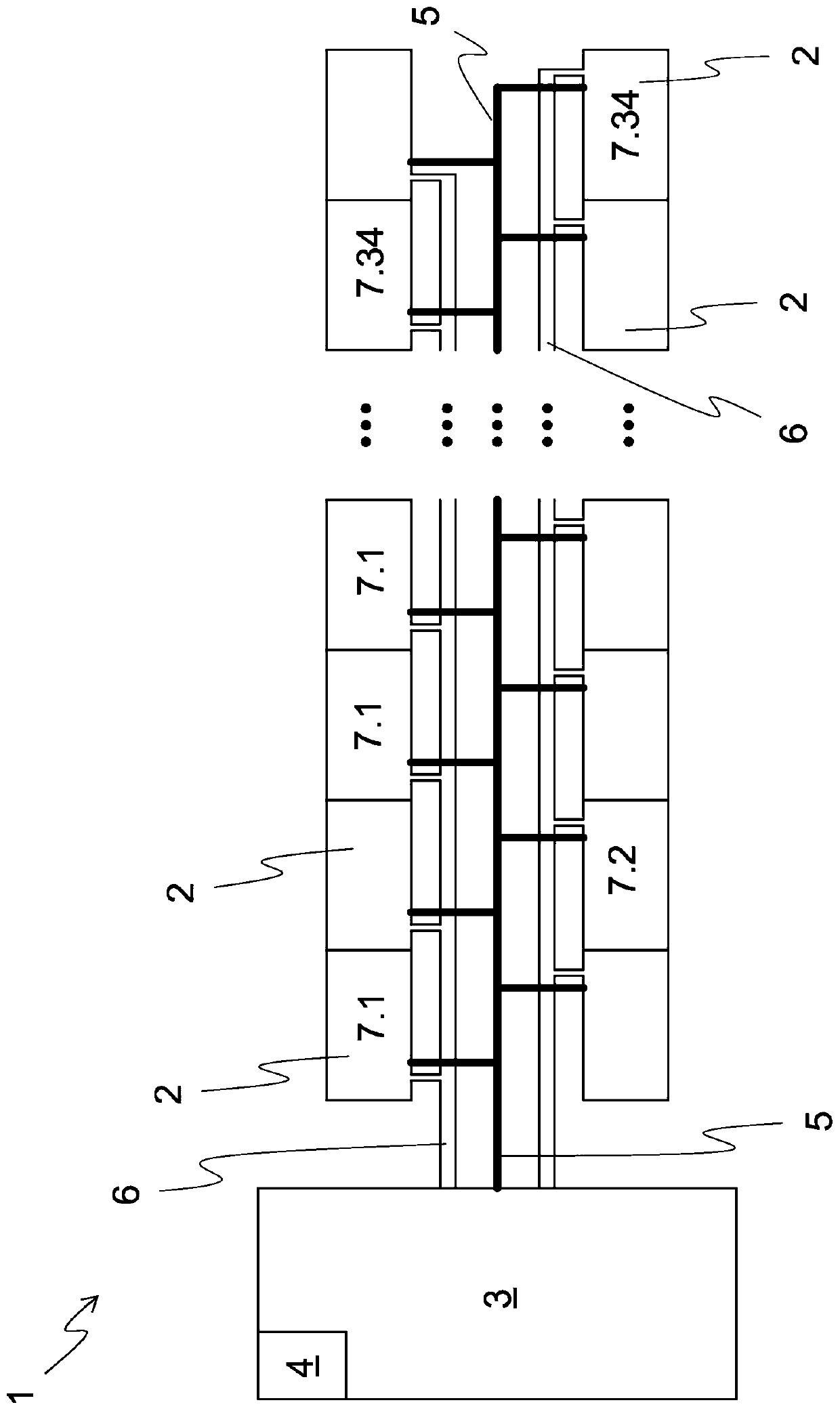

[0025] figure 1 A schematic top view of a textile machine 1 according to the invention is shown, with a plurality of similar workstations 2 , only a few of which are labeled for clarity.

[0026] The textile machine 1 can be any textile machine 1 having a plurality of similar workstations 2 , in particular a spinning or winding machine. In particular, textile machines 1 for the production of cross-winding packages, in particular open-end spinning machines and air-jet spinning machines, should be mentioned here.

[0027] Furthermore, the textile machine 1 has a machine head 3 which includes a central control unit 4 . In an alternative embodiment not shown in the figures, a decentralized control mechanism is used instead of the central control unit 4 to operate the textile machine 1 .

[0028] The handpiece 3 supplies electrical energy or compressed air to the station 2 via an electrical cable 5 and a compressed air tube 6 . Station 2 may require other resources, such as nega...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com