A kind of chitosan-silk fibroin edible film and preparation method thereof

A technology of silk fibroin and chitosan, applied in the field of edible film, can solve the problems of poor moisture resistance, not edible film, easy aging and cracking of the film, etc., achieving good moisture resistance, delaying aging and browning, equipment less dependent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

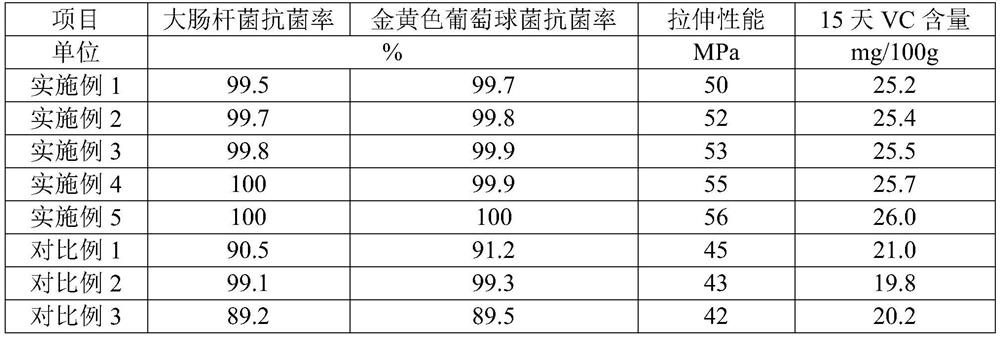

Examples

preparation example Construction

[0022] The present invention relates to a kind of preparation method of chitosan-silk fibroin edible film, is characterized in that, comprises the following steps:

[0023] Step S1, preparation of quaternized chitosan solution: dissolving quaternized chitosan in deionized water, stirring at 50-60° C. for 15-30 minutes to form a solution, and then adding mass percent concentration of 1-3% glacial acetic acid, continue to insulate and mechanically stir for 35-45 minutes with a rotating speed of 450-550rpm, and then let it stand to obtain a clear and transparent light yellow quaternized chitosan solution;

[0024] Step S2, preparation of silk fibroin solution: dissolving nano-silk fibroin in deionized water, stirring at 55-65°C for 20-35 minutes to form a solution, and then adding 0.5-1.5% of silk fibroin to the solution Glacial acetic acid, continue to insulate and mechanically stir for 25-35 minutes with a rotating speed of 500rpm, and then let it stand to obtain a silk fibroin...

Embodiment 1

[0032] This example provides a kind of preparation method of chitosan-silk fibroin edible film, is characterized in that, comprises the steps:

[0033] Step S1, preparation of quaternized chitosan solution: Dissolve 10 g of quaternized chitosan in 1 L of deionized water, stir at 50° C. for 15 minutes to form a solution, and then add % of glacial acetic acid 8mL, continue to insulate and mechanically stir for 35 minutes with the rotating speed of 450rpm, leave standstill behind, obtain clear and transparent micro-yellow quaternized chitosan solution;

[0034] Step S2, preparation of silk fibroin solution: dissolve 9 g of nano silk fibroin in 1 L of deionized water, stir at 55° C. for 20 minutes to form a solution, and then add 8 mL of glacial acetic acid with a concentration of 0.5% by mass to the solution , continue to insulate and mechanically stir for 25 minutes with a rotating speed of 500rpm, and then let it stand to obtain a silk fibroin solution;

[0035]Step S3, prepar...

Embodiment 2

[0040] This example provides a kind of chitosan-silk fibroin edible film, and it is basically consistent with example 1, and difference is, the proportioning of quaternized chitosan described in step S1, deionized water, glacial acetic acid 10g: 1.2L: 9mL; the proportioning of nano silk fibroin, deionized water, and glacial acetic acid described in step S2 is 9.5g: 1.1L: 9mL; the quaternized chitosan solution, silk The mass ratio of plain protein solution, glycerol, polyethylene glycol and surfactant is 1:1:0.03:0.03:0.02; Described surfactant is Tween 80; Chitosan-silk fibroin described in step S4, The mass ratio of water and alginic acid is 3:100:0.3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com