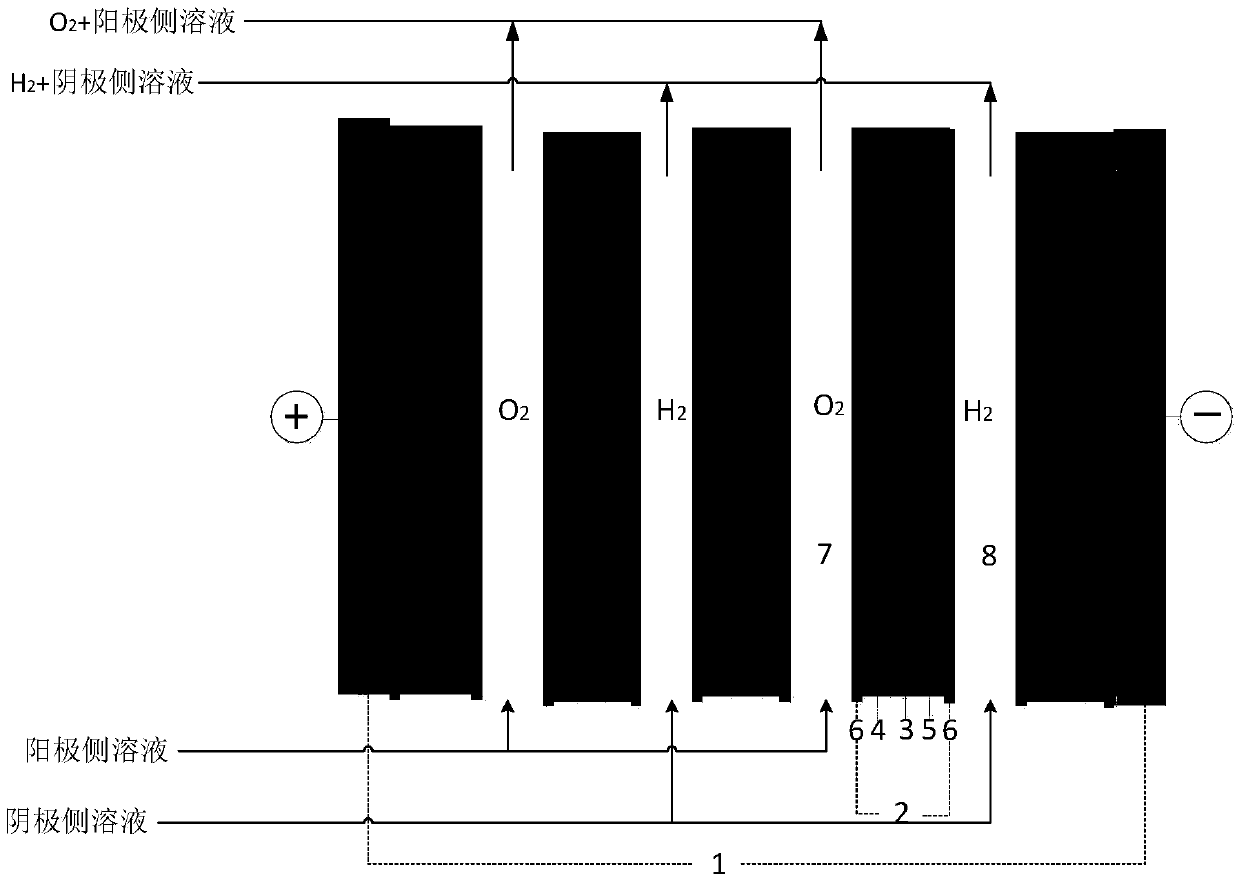

Method and device for producing hydrogen through water electrolysis

A technology for electrolyzing water and electrolyte, applied in electrolysis process, electrolysis components, cells, etc., can solve problems such as increased energy consumption, achieve the effect of reducing energy consumption and improving electrolysis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The electrolyte on the cathode side is water at 80°C, the electrolyte on the anode side is 30% by weight KOH solution at 80°C, the absolute value of the pH difference between the electrolyte on the cathode side and the electrolyte on the anode side is 8, and the ion exchange membrane uses Nafion117 membrane (purchased from DuPont (DuPont Company), the same below), the cathode catalyst and the anode catalyst are both Pt, apply a 2.2V DC voltage, and generate H under the action of the cathode side electrolyte cathode catalyst 2 , the anode side electrolyte produces O under the action of the anode catalyst 2 , energy consumption is 4.0kWh / Nm 3 .

Embodiment 2

[0054] The cathode side electrolyte is 20 wt% H at 80°C 2 SO 4 solution, the electrolyte on the anode side is water at 80°C, the absolute value of the pH difference between the electrolyte on the cathode side and the electrolyte on the anode side is 5, the ion exchange membrane is Nafion117 membrane, the cathode catalyst and the anode catalyst are both Pt, and 2.2 V DC voltage, so that the electrolyte on the cathode side generates H under the action of the cathode catalyst 2 , the anode side electrolyte produces O under the action of the anode catalyst 2 , energy consumption is 3.9kWh / Nm 3 .

Embodiment 3

[0056] The electrolyte on the cathode side is water at 50°C, the electrolyte on the anode side is 30% by weight KOH solution at 50°C, the absolute value of the pH difference between the electrolyte on the cathode side and the electrolyte on the anode side is 7.8, and the ion exchange membrane adopts X37-50 anion exchange membrane (purchased from Dioxide Materials (carbon dioxide material company)), the cathode catalyst and the anode catalyst are both Ni, and a 2.2V DC voltage is applied to make the cathode side electrolyte generate H under the action of the cathode catalyst. 2 , the anode side electrolyte produces O under the action of the anode catalyst 2 , energy consumption is 4.9kWh / Nm 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com