Organic solvent liquid compression rate online test method and system based on micro-upgraded volume

An organic solvent and liquid compression technology, which is applied to the online measurement of the compressibility of organic solvents under high pressure, and in the field of ultra-high pressure liquid phase analysis, can solve problems such as crossover and complex implementation processes, and achieve good universality, simple calculation process, highly operable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

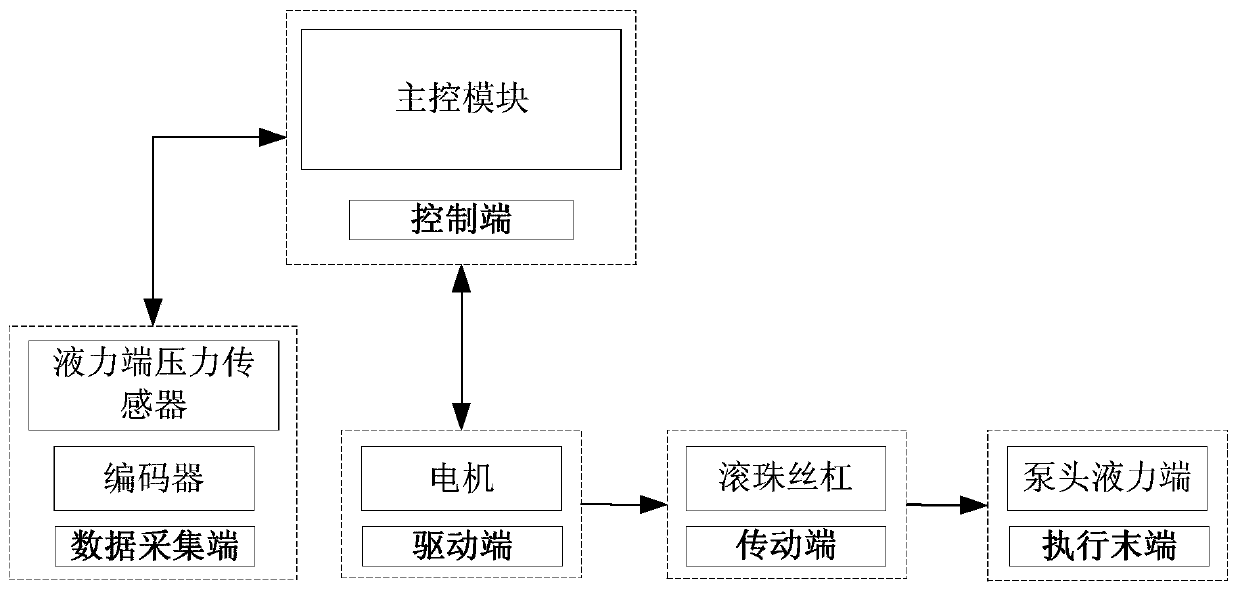

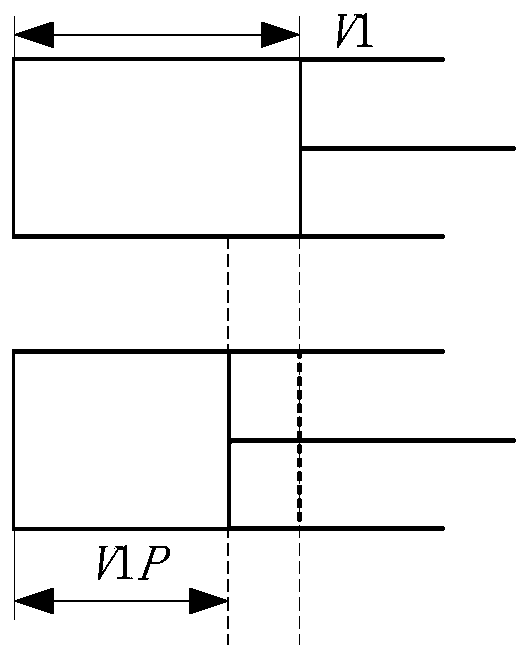

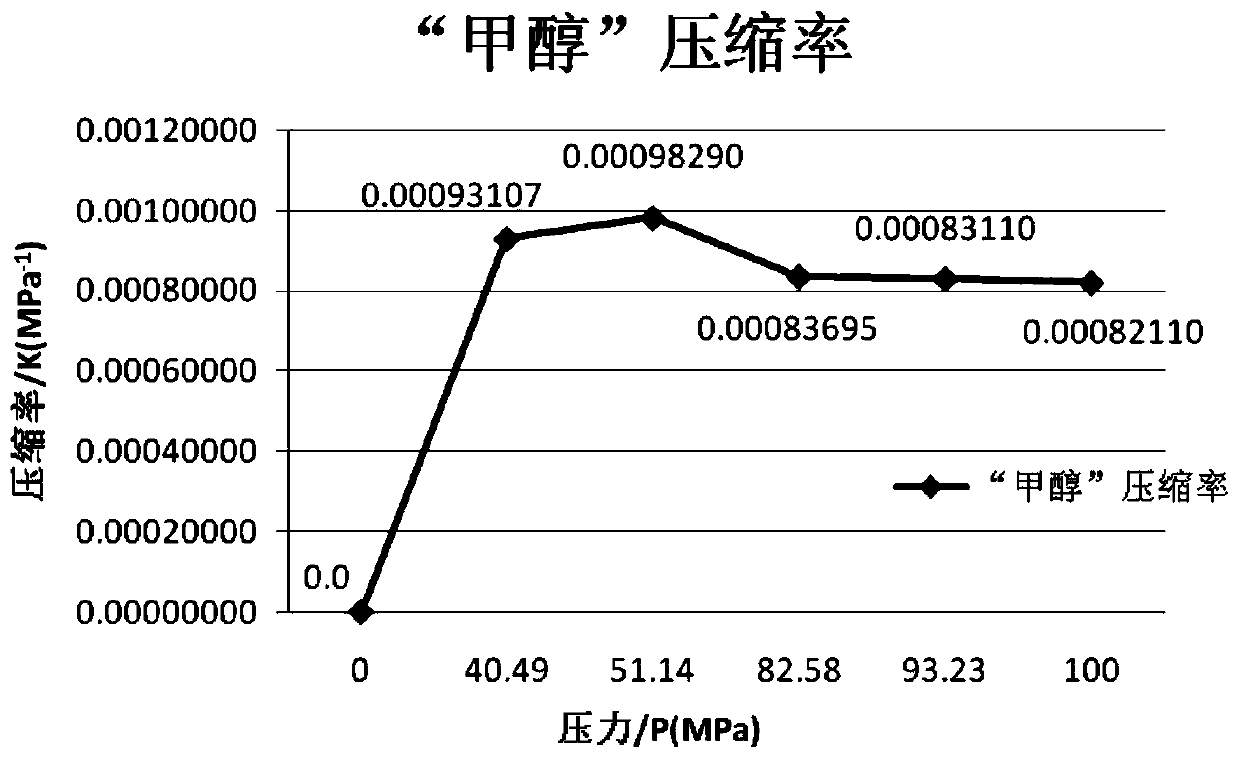

[0049] The present invention proposes an on-line test method and system for liquid compression rate of organic solvents based on micro-upgraded volume, using micro-upgraded volume at the liquid end of a liquid-phase pump, and controlling the reciprocating motion of the liquid-phase pump to compress the organic solvent online and read it in real time The pressure value of the hydraulic system correlates the pressure increment with the compression value, so as to realize the online test of the compressibility of the organic solvent liquid in microliter volume. In order to solve the influence of the flow accuracy caused by the ultra-high pressure compression of the liquid solvent in the process of transporting the organic solvent by the high-precision ultra-high pressure liquid phase pump; when the ultra-high pressure and high-precision or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com