A fully automatic film and coil packaging integrated production process

A production process, film roll technology, applied in the field of fully automatic film roll packaging integrated production process, can solve the problems of lower production efficiency, enterprise competitiveness, high equipment cost, etc., to reduce equipment cost and wrap quickly Thoroughly, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

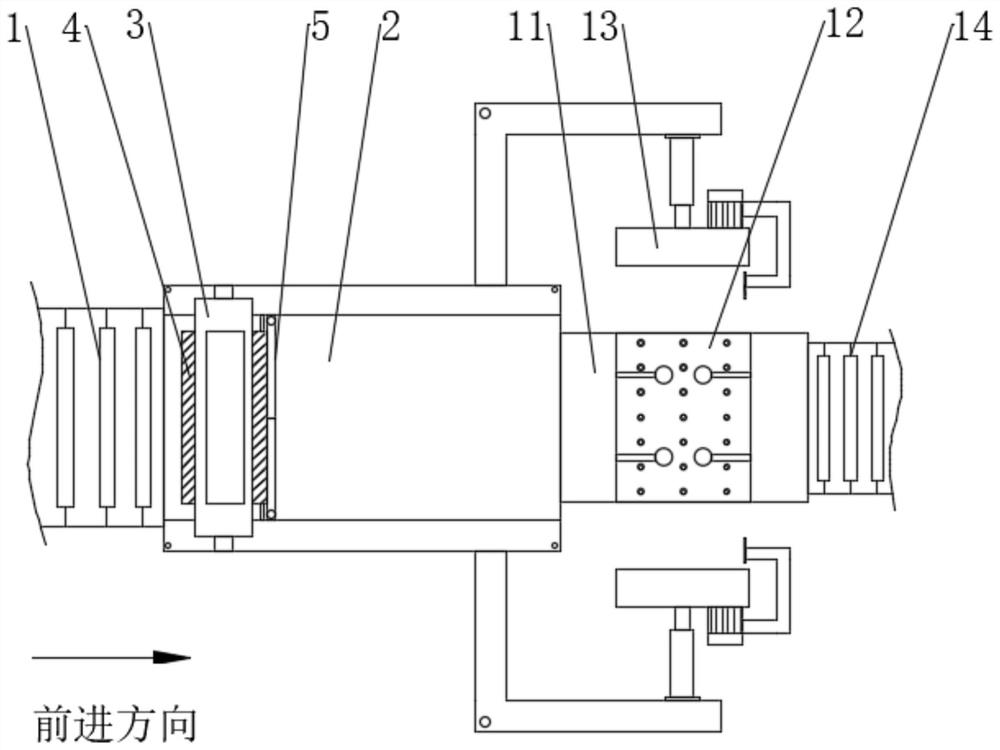

[0049] see figure 1 , an integrated production process for fully automatic film and coil packaging, comprising the following steps:

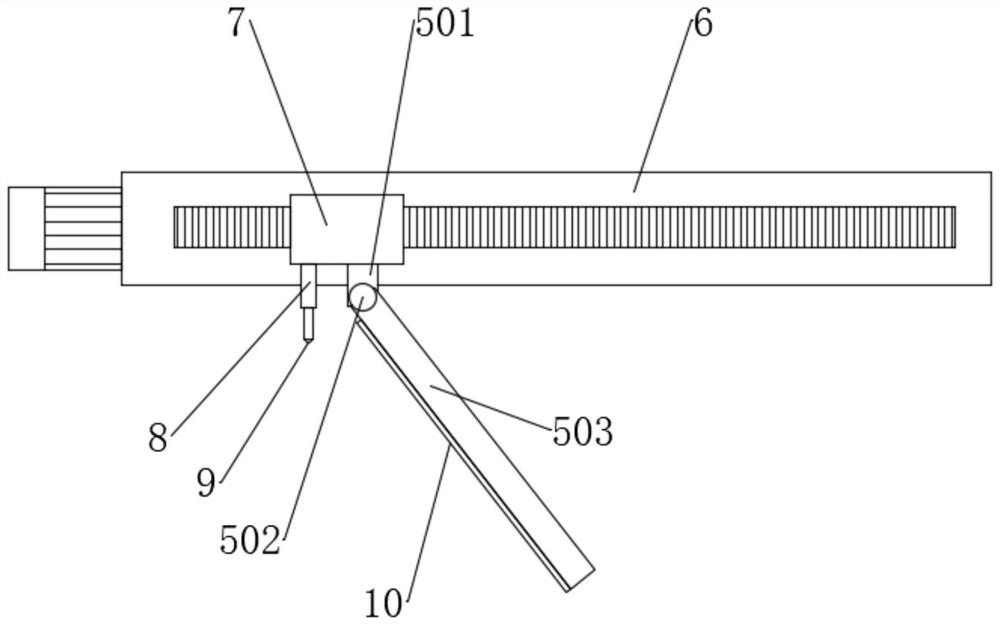

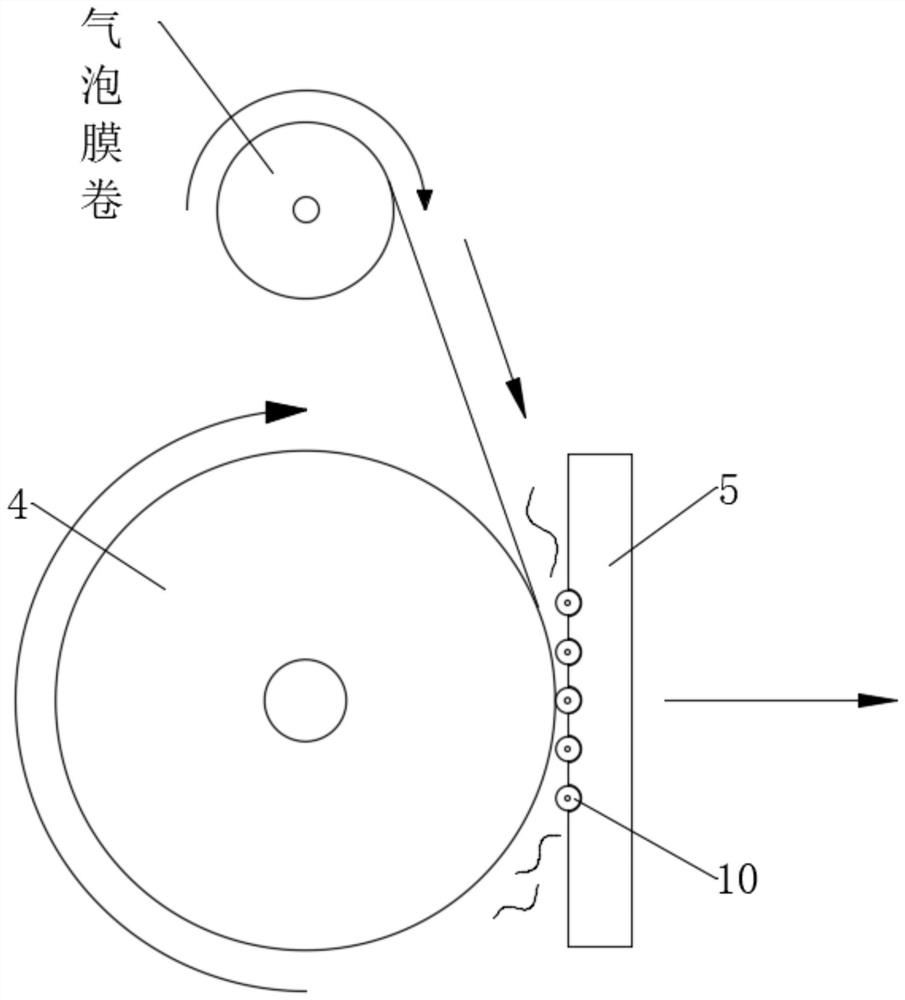

[0050] S1. The film coil 4 to be packaged is transported to the static packaging station 2 by the horizontal conveying mechanism 1, the film coil 4 is positioned by the positioning guide mechanism, and the bubble film is wound by the bubble film rolling mechanism 3 at the same time;

[0051] S2. Relying on the inclined surface of the static packaging table 2, the film coil 4 rolls down to complete the wrapping of the air bubble film, and the positioning and guiding mechanism guides and controls the speed in real time, and performs hot-melt coating on the wrapped air bubble film;

[0052] S3. After the hot-melt is completed, the film coil 4 falls onto the moving packaging table 11 to achieve equal depth bonding and clamping, and the paper cover fastening mechanism 13 on both sides of the tail end of the static packaging table 2 pairs the two ends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com