Excellent boiling-resistant and neutral-salt-mist-resistant polyester resin for low-temperature curing type powder and preparation method thereof

A technology of polyester resin and water boiling resistance, applied in powder coatings, polyester coatings, coatings, etc., can solve the problems of water boiling resistance, neutral salt spray resistance, and inability to cure at low temperature with TGIC system, achieving outstanding performance Boiling resistance and neutral salt spray resistance, excellent boiling resistance and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

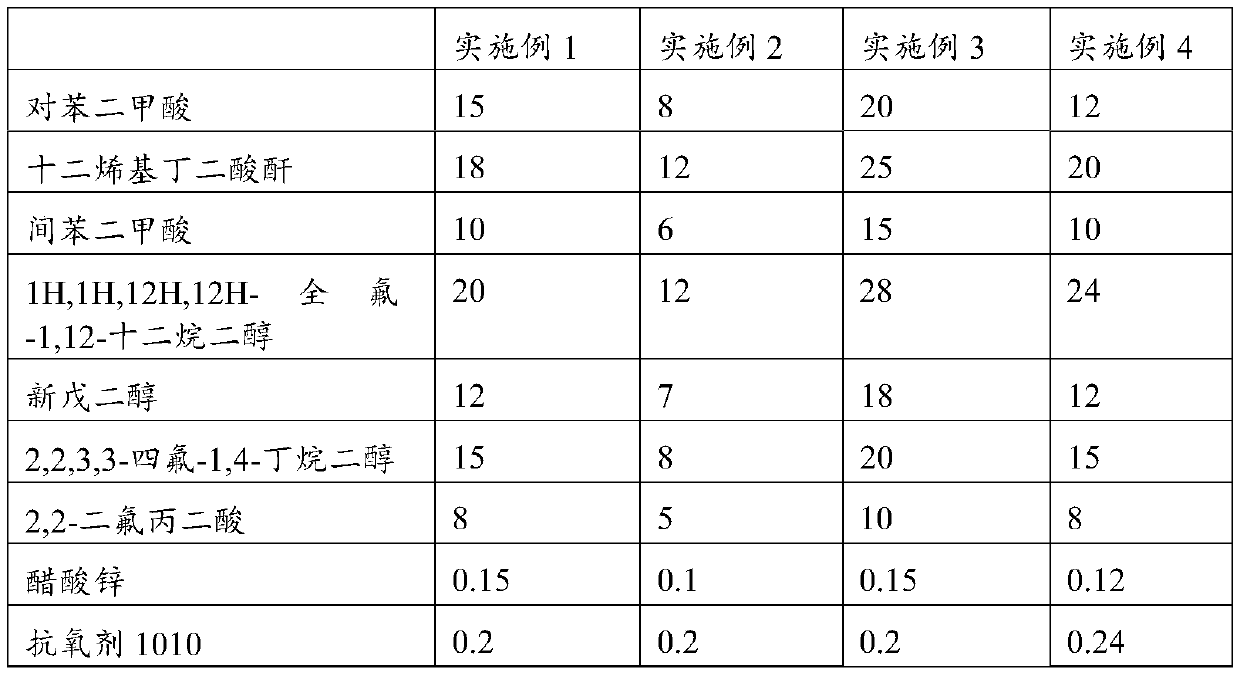

[0038] The preparation method of the TGIC type powder coating polyester resin of water boiling resistance and neutral salt spray comprises the following steps:

[0039] (1) Prepare each raw material, and the consumption of each raw material is as follows Table 1. Add the catalyst zinc acetate, 1H, 1H, 12H, 12H-perfluoro-1,12-dodecanediol, terephthalic acid, dodecenylsuccinic anhydride into the reactor at a rate of 20°C / h Gradually raise the temperature to 150°C, and keep it warm for 6 hours; then raise the temperature to 190°C at a rate of 10°C / h, and keep it warm for 5 hours;

[0040] (2) When the acid value of the reactant is 55mgKOH / g, add neopentyl glycol and isophthalic acid to the reaction kettle to carry out sufficient esterification polymerization reaction, and slowly heat up to 220°C at a rate of 7°C / h. And insulation continued polymerization reaction 6h;

[0041] (3) When the acid value of the reactant is 55mgKOH / g, lower the temperature to 210°C, add 2,2,3,3-tetra...

Embodiment 5

[0065] The formula of high acid value TGIC system powder coating is usually as follows in parts by weight:

[0066]

[0067]

[0068] Coating coating preparation: According to the formula of high acid value TGIC powder coating, all materials are mixed evenly, extruded with twin-screw extruder, pressed into tablets, crushed, and then crushed and sieved to make powder coating. The powder coating is sprayed on the surface-treated aluminum plate with an electrostatic spray gun, and is rapidly cured at 150°C / 15min to obtain a powder coating.

[0069] Coating index testing is based on GB / T 21776-2008 "Powder Coatings and Coatings Testing Standard Guide"; water boiling performance test GB 5237.4-2008 "Aluminum Aluminum Building Profiles Part 4 Powder Spraying Profiles" part 5.4.10; The neutral salt spray test is based on GB / T 1771-91 "Determination of the neutral salt spray resistance of paints and varnishes".

[0070] Table 3 embodiment and comparative example coating basic p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com