A kind of water-based drilling fluid lubricant and magnetic polyether used therein and preparation method thereof

A water-based drilling fluid and lubricant technology, which is applied in the field of oil drilling, can solve the problems of continuous lubrication in long horizontal sections, etc., achieve good cycle stability, improve continuous lubrication effect, and improve lubrication effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

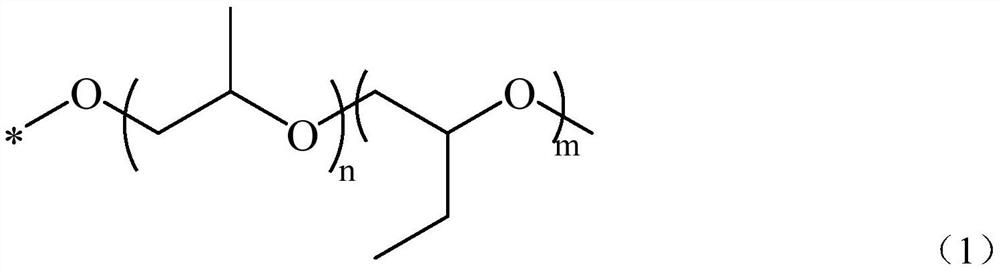

[0029] Preparation of magnetic polyether: Weigh 6g of hydroxylated nano-Fe 3 o 4 The magnetic particles and 1g of monomethylamine are fully mixed at room temperature, and the reaction system is heated to 70°C under nitrogen protection with a purity of 99.99%. The reaction temperature is maintained and propylene oxide and 1,2-butylene oxide are added separately In the reaction system, after 12-24 hours of mechanical stirring at constant temperature, the stirring was stopped, and the reaction system was naturally cooled to room temperature, and methanol was slowly added to the reaction system to end the polyether chain segment with a methyl group to obtain a magnetic Fe 3 o 4 Polyether crude product;

[0030] Remove the unreacted raw materials and methanol from the crude magnetic polyether product under reduced pressure, add concentrated hydrochloric acid to neutralize the pH value of the system to neutral, wash with deionized water, leave the liquid separation to remove the w...

Embodiment 2

[0034] Preparation of magnetic polyether: Weigh 8g of hydroxylated nano-Ni-Fe magnetic particles and 1.5g of dimethylamine and mix them fully at room temperature, and heat the reaction system to 80°C under nitrogen protection with a purity of 99.99%, and keep the reaction temperature Add 40g of propylene oxide and 30g of 1,2-butylene oxide into the reaction system respectively, and then stop stirring at 80°C for 24 hours with mechanical stirring at a constant temperature, then cool down to room temperature naturally, and slowly add 10g of methanol into the reaction system to make the polymerization The ether segment is terminated with a methyl group to obtain a crude magnetic Ni-Fe polyether product;

[0035] Remove the unreacted raw materials and methanol from the crude magnetic polyether product under reduced pressure, add concentrated hydrochloric acid to neutralize the pH value of the system to neutral, wash with deionized water, leave the liquid separation to remove the wa...

Embodiment 3

[0039] Weigh 14g of hydroxylated nano-cobalt oxide magnetic particles and 2g of liquid basic catalyst trimethylamine and mix them thoroughly at room temperature, heat the reaction system to 90°C under nitrogen protection with a purity of 99.99%, maintain the reaction temperature and mix 30g of epoxy Propane and 30g 1,2-butylene oxide were added to the reaction system respectively, and the reaction was mechanically stirred at a constant temperature at 90°C for 24 hours, then the stirring was stopped, and the reaction system was naturally cooled to room temperature, and 10g of methanol was slowly added to the reaction system to make the polyether chain segment form in form End-capping obtains magnetic polyether crude product;

[0040]Remove the unreacted raw materials and methanol from the crude magnetic polyether product under reduced pressure, add concentrated hydrochloric acid to neutralize the pH value of the system to neutral, wash with deionized water, leave the liquid sepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com