An easy-to-grind cement-based interior wall putty

An inner wall, cement-based technology, applied in the direction of filling slurry, etc., can solve the problems of laborious and time-consuming grinding, poor grinding performance, restricting the application of putty, etc., and achieve the effect of preventing the rapid volatilization of water and prolonging the surface hardness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

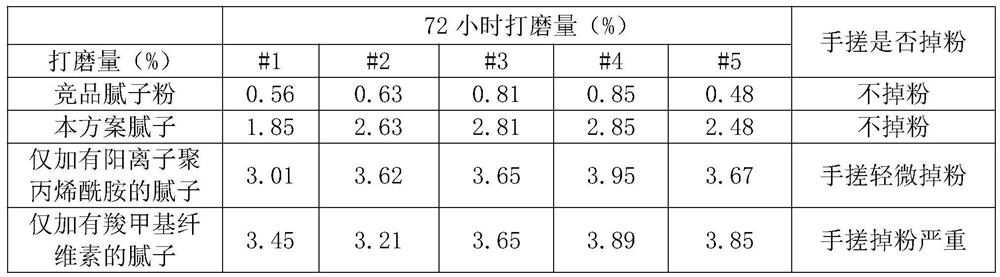

Image

Examples

Embodiment 1

[0027] An easy-to-polish cement-based interior wall putty, which contains, by weight, 75-90 parts of double fly powder; 10-20 parts of white cement; 0.5-1 part of dispersible organic rubber powder; 0.1-0.5 parts of expansion soil; 1-1.5 parts of cationic polyacrylamide; 0.5-1 parts of carboxymethyl cellulose; 0.1-0.2 parts of silicon dioxide, 0.3-0.5 parts of hydroxypropyl cellulose ether, 1-5 parts of poly Vinyl alcohol fine powder 1-5 parts.

[0028] Among them, preferably, hydroxypropyl cellulose ether has a viscosity of 60,000 to 70,000. The particle size of polyvinyl alcohol fine powder is 300-400 mesh. Shuangfei powder has a whiteness of 83 degrees and a particle size of 250 mesh. The whiteness of white cement is 90 degrees. The dispersible organic rubber powder is vinyl acetate vinyl copolymer. The molecular weight of cationic polyacrylamide is 15-20 million, and the particle size is 100-110 mesh.

[0029] At the time of preparation:

[0030] S1. In the heating an...

Embodiment 2

[0035] An easy-to-polish cement-based interior wall putty, 75-90 parts of Shuangfei powder; 10-20 parts of white cement; 0.5-1 part of dispersible organic rubber powder; 0.1-0.5 parts of expansive soil; 1-1.5 parts Cationic polyacrylamide; 0.5-1 parts of carboxymethyl cellulose; 0.1-0.2 parts of silicon dioxide, 0.3-0.5 parts of hydroxypropyl cellulose ether, 1-5 parts of polyvinyl alcohol fine powder 1- 5 servings.

[0036] Among them, preferably, hydroxypropyl cellulose ether has a viscosity of 60,000 to 70,000. The particle size of polyvinyl alcohol fine powder is 300-400 mesh. Shuangfei powder has a whiteness of 83 degrees and a particle size of 250 mesh. The whiteness of white cement is 90 degrees. The dispersible organic rubber powder is vinyl acetate vinyl copolymer. The molecular weight of cationic polyacrylamide is 15-20 million, and the particle size is 100-110 mesh.

[0037] Preparation, product requirements and storage are all the same as in Example 1.

Embodiment 3

[0039] An easy-to-polish cement-based interior wall putty, comprising: 75-90 parts of double fly powder; 10-20 parts of white cement; 0.5-1 part of dispersible organic rubber powder; 0.1-0.5 parts of expansion soil; 1-1.5 parts of cationic polyacrylamide; 0.5-1 parts of carboxymethyl cellulose; 0.1-0.2 parts of silicon dioxide, 0.3-0.5 parts of hydroxypropyl cellulose ether, 1-5 parts of poly Vinyl alcohol fine powder 1-5 parts.

[0040] Among them, preferably, hydroxypropyl cellulose ether has a viscosity of 60,000 to 70,000. The particle size of polyvinyl alcohol fine powder is 300-400 mesh. Shuangfei powder has a whiteness of 83 degrees and a particle size of 250 mesh. The whiteness of white cement is 90 degrees. The dispersible organic rubber powder is vinyl acetate vinyl copolymer. The molecular weight of cationic polyacrylamide is 15-20 million, and the particle size is 100-110 mesh.

[0041] Preparation, product requirements and storage are all the same as in Examp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com