Spunlace composite nonwoven fabric and preparation method thereof

A non-woven and spunlace technology, applied in needle punching machines, non-woven fabrics, textiles and papermaking, etc., can solve the problems of product performance uniformity and reduced stability, and achieve difficult interface separation, good hand feel, and shape retention. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of above-mentioned spunlace composite non-woven fabric, comprises the following steps:

[0039]S1. High-strength fiber web: laying high-strength fibers into a web to prepare a high-strength fiber web;

[0040] S2. Viscose fiber web: laying viscose fiber into a web to prepare a viscose fiber web;

[0041] S3. Spunlace reinforcement: laminate high-strength fiber webs and viscose fiber webs with a mass ratio of 9:1 to 5:5, and perform composite spunlace on the laminated composite fiber webs to obtain a composite non-woven fabric after spunlace reinforcement;

[0042] S4. Drying and molding: drying the spunlace-reinforced composite non-woven fabric, then winding, removing defects, slitting and packaging to obtain a spunlace composite non-woven fabric.

[0043] Preferably, in step S3, the composite spunlace uses high-pressure water flow to perform 5-10 spunlace processes on the laminated composite fiber web, and the water needle pressure of each spunl...

Embodiment 1

[0058] The spunlace composite non-woven fabric provided in this example is made of polyester fiber web and viscose fiber web with a mass ratio of 5:1 and is spunlace reinforced, and its surface density is 120g / m 2 , the polyester fiber fineness is 5dtex, and the viscose fiber fineness is 0.8dtex, and its preparation method comprises the following steps:

[0059] S1. Polyester fiber web: laying polyester fibers with a fineness of 5dtex into a web to prepare a polyester fiber web;

[0060] S2. Viscose fiber web: laying viscose fiber with a fineness of 0.8dtex into a web to prepare a viscose fiber web;

[0061] S3. Spunlace reinforcement: The polyester fiber web and the viscose fiber web with a mass ratio of 5:1 are laminated, and the laminated composite fiber web is composited with five spunlace processes to obtain a composite nonwoven after spunlace reinforcement. cloth;

[0062] Among them, the water needle pressure P of the first spunlace process 1 is 2MPa, the water needl...

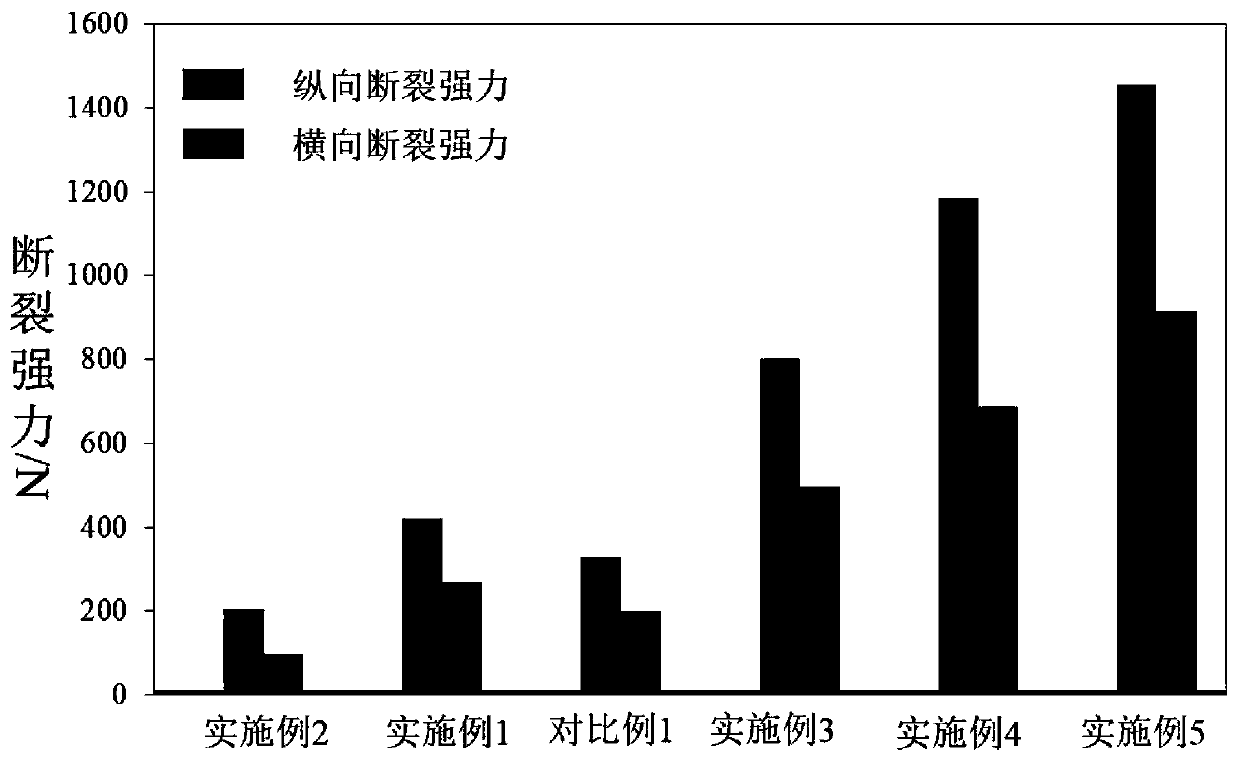

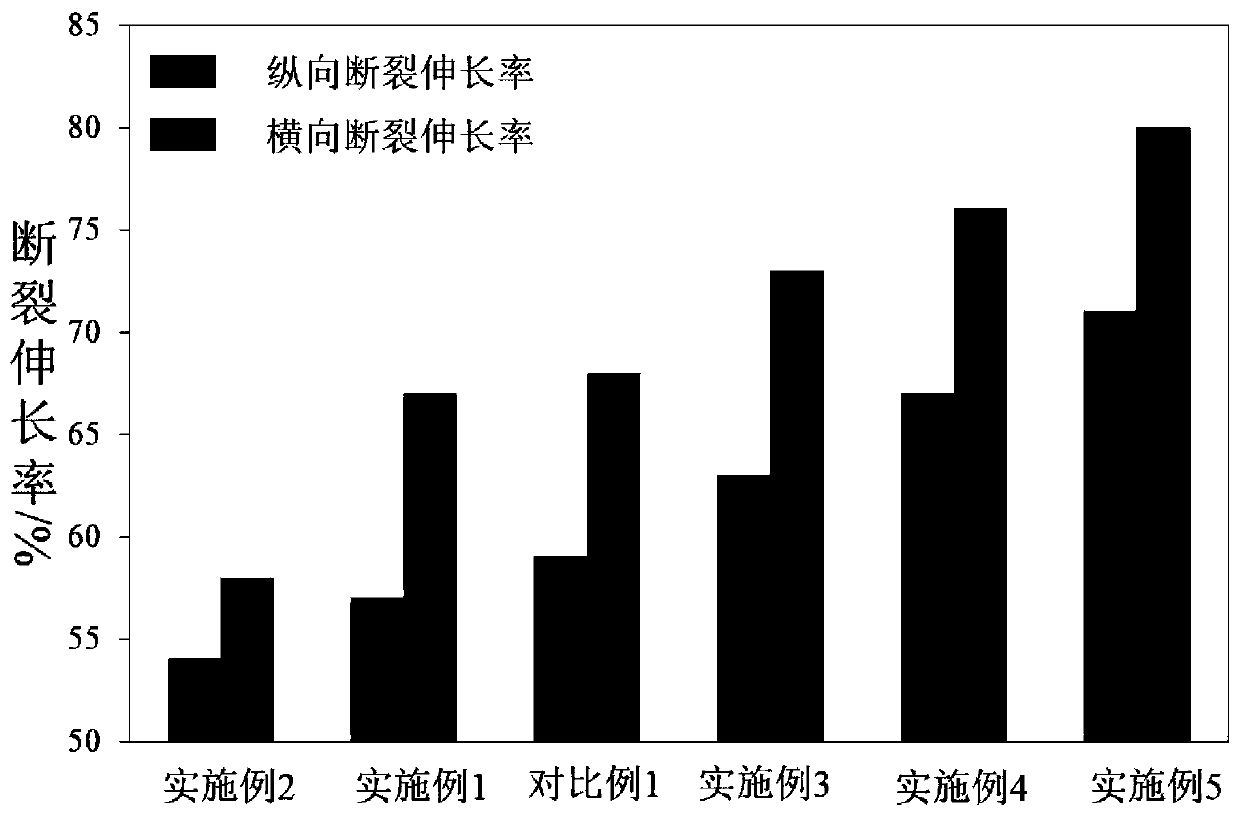

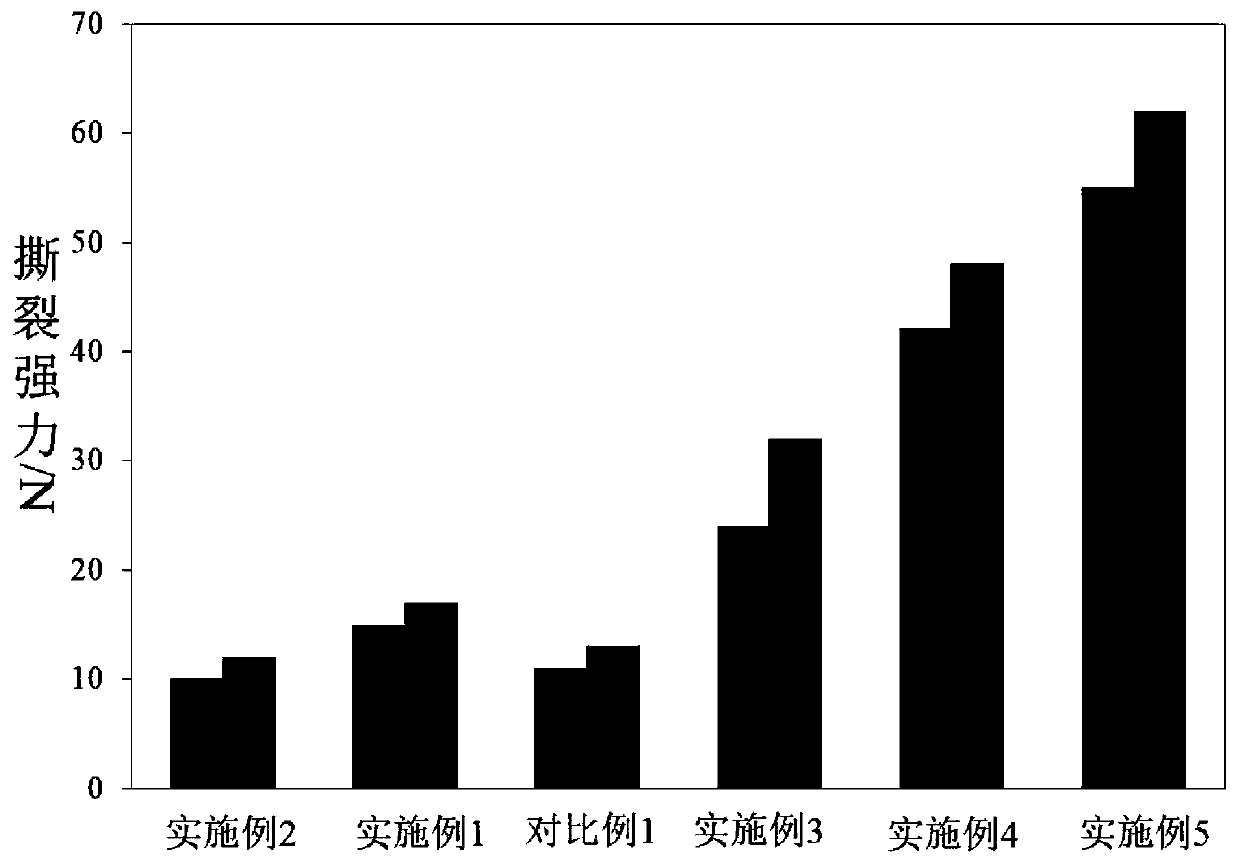

Embodiment 2~11

[0065] The surface density, mass ratio and fineness of polyester fibers and viscose fibers of the spunlace composite nonwovens provided in Examples 2 to 11 are shown in Table 1, wherein the preparation methods of Examples 2 and 3 and Examples 6 to 8 All are substantially the same as in Embodiment 1, and will not be repeated here. The water needle pressures of the five spunlace processes in Example 4 are 2MPa, 5MPa, 11MPa, 10.5MPa and 9.5MPa respectively, and the water needle pressures of the five spunlace processes in Example 5 are 2MPa, 5MPa, 14MPa, 13.5MPa respectively and 12.5Mpa, others are basically the same as in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

| Fiber fineness | aaaaa | aaaaa |

| Fiber fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com