Pi-energy fuel catalyst core

A fuel catalytic core and fuel technology, which is applied to combustion engines, internal combustion piston engines, combustion air/combustion-air treatment, etc., can solve the problems of high use cost, affecting the life of fuel injectors, and interfering with the work of electronic components, etc. Improve the utilization rate of combustion power, reduce exhaust pollutant emissions, and improve the effect of fuel catalysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described below with reference to specific examples. Those skilled in the art can understand that these examples are only used to illustrate the present invention and do not limit the scope of the present invention in any way.

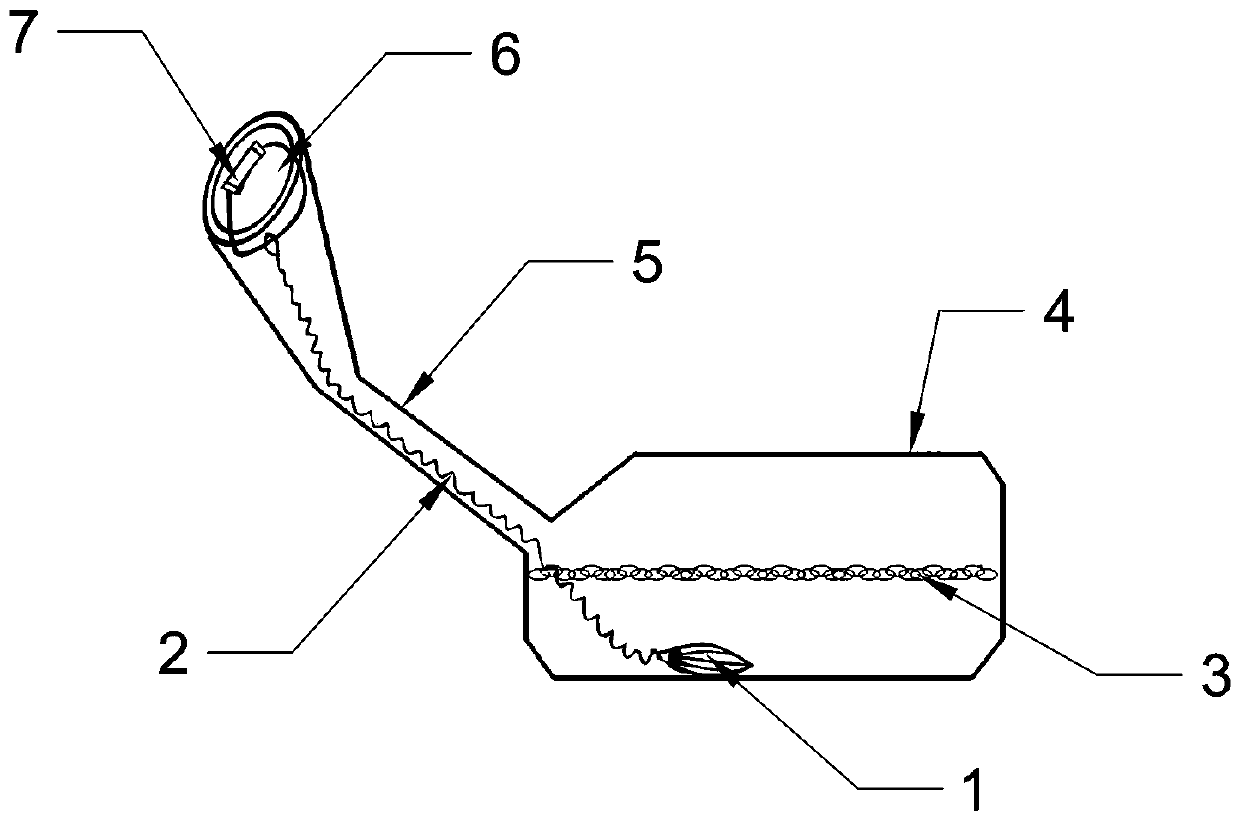

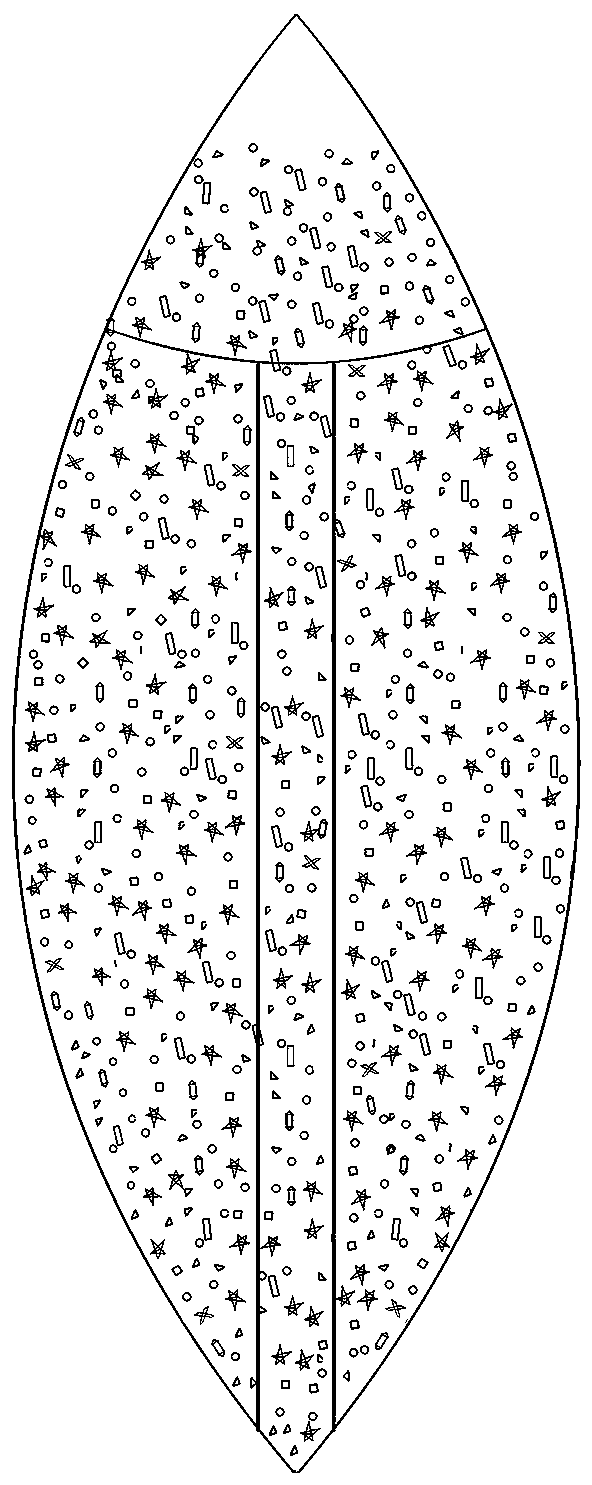

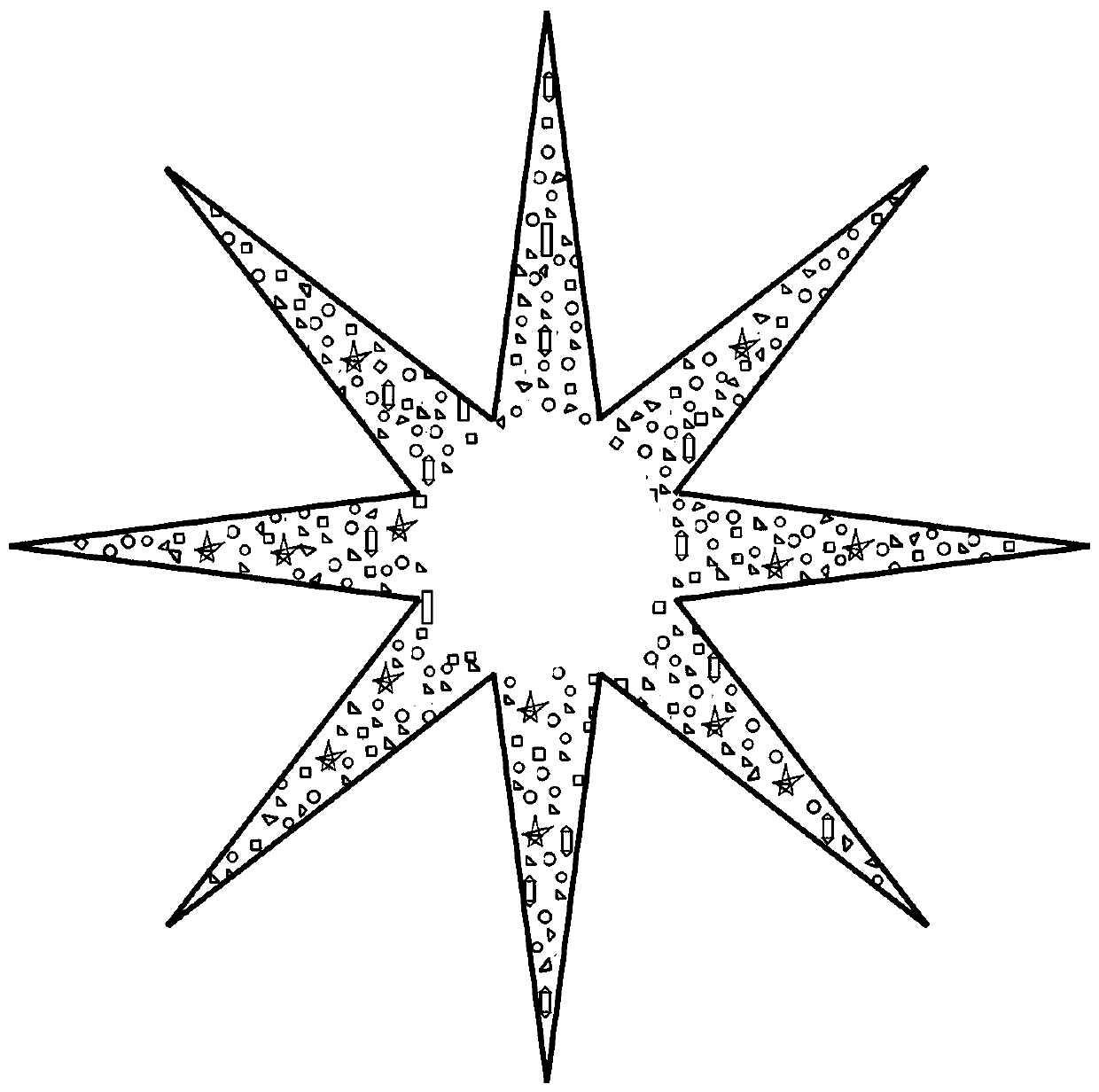

[0020] A π-energy fuel catalyst core, such as Figure 1 to Figure 3 As shown, it includes a crystal and a carrier; the material of the carrier is fluorine rubber; the carrier adopts an ellipsoid-shaped 8-piece sector structure; the crystal adopts various technical elements such as high-energy composite materials and rare metals, and produces 7 kinds of high-frequency vibrations of different frequencies Energy crystals, 7 different crystals can produce far infrared rays and near infrared rays at the same time, all of which are permanent carriers produced by physical endogenous sources; the crystals are vertically implanted on the carrier to form a fuel catalytic core (1);

[0021] The fuel catalytic core (1) is plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com