High-efficiency integrated treatment process for landfill leachate membrane concentrated solution

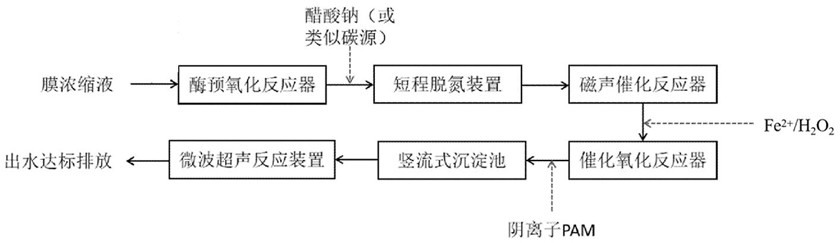

A landfill leachate and treatment process technology, which is applied in the field of high-efficiency integrated treatment process of landfill leachate membrane concentrate, can solve problems such as high difficulty, low economic cost, and inconspicuous removal effect, and achieve carbon source reduction and more catalytic active points , high oxidation reaction rate and high oxidation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

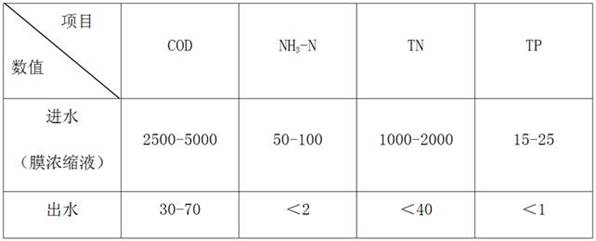

[0025]Wastewater source: a landfill in Beijing, with a daily water treatment capacity of 2,200m³ / d. Currently, there are two sets of treatment processes: one is a 1,200-ton / day facility "regulating tank + anaerobic reactor + MBR + NF + RO"; the other The set is a 1000 ton / day skid-mounted equipment "mixing tank + biological turntable + biological aeration tank + sedimentation tank + sand filter + two-stage DTRO"; the concentrated solution of NF, RO and DTRO is produced every day, a total of 500m³ / d;

[0026] Our company adopts the combined process of biological enzyme oxidation-short-path nitrification and denitrification-heterogeneous metal chemical catalysis-free radical oxidation to treat the membrane concentrate wastewater. ) the discharge standard required in Table 2, which realizes the full quantitative treatment of the landfill leachate membrane concentrate.

[0027] technical parameter:

[0028] The processing scale of membrane concentrate is 500 tons per day. Enzyme...

Embodiment 2

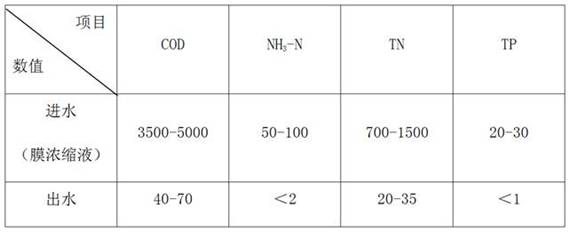

[0040] Wastewater source: The treatment scale of landfill leachate in a landfill in Jiangsu is 1,000 tons per day. The treatment process mainly adopts "regulating tank + first-level anoxic biochemical tank (A) + first-level aerobic biochemical tank (O) + second-level biochemical tank Anoxic biochemical tank (A) + secondary aerobic biochemical tank (O) + MBR + NF + RO", the membrane concentrate produced by NF and RO is collected in the pool, and the water volume of the concentrate is 250 tons / day;

[0041] Our company adopts the combined process of biological enzyme oxidation-short-path nitrification and denitrification-heterogeneous metal chemical catalysis-free radical oxidation to treat the membrane concentrate wastewater. ) the discharge standard required in Table 2, thus the membrane concentrate implements the engineering scale application of the content of the present invention, and realizes the full quantification of the landfill leachate membrane concentrate.

[0042] t...

Embodiment 3

[0055] Wastewater source: The treatment scale of landfill leachate in a landfill in Guangxi is 600 tons / day. The treatment process mainly adopts "regulating tank + first-level anoxic biochemical tank (A) + first-level aerobic biochemical tank (O) + second-level Anoxic biochemical pool (A) + secondary aerobic biochemical pool (O) + MBR+NF+RO";

[0056] At present, the landfill has been closed, and the existing biochemical treatment facilities for leachate mainly deal with 300,000 tons of leachate stored in the big pit and some fresh leachate from the landfill garbage mountain, which is mainly characterized by high nitrogen content.

[0057] The leachate produced by the existing biochemical + membrane treatment facilities adopts the combined process of biological enzyme oxidation-short-path nitrification and denitrification-heterogeneous metal chemical catalysis-free radical oxidation to treat the membrane concentrate wastewater, with a designed treatment scale of 300 tons / day, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com