OLED panel display defect detection equipment

A defect detection and panel display technology, which is applied in the direction of measuring devices, static indicators, optical instrument testing, etc., can solve defects and other problems, achieve the effect of simple structure, reduce labor intensity, and improve detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

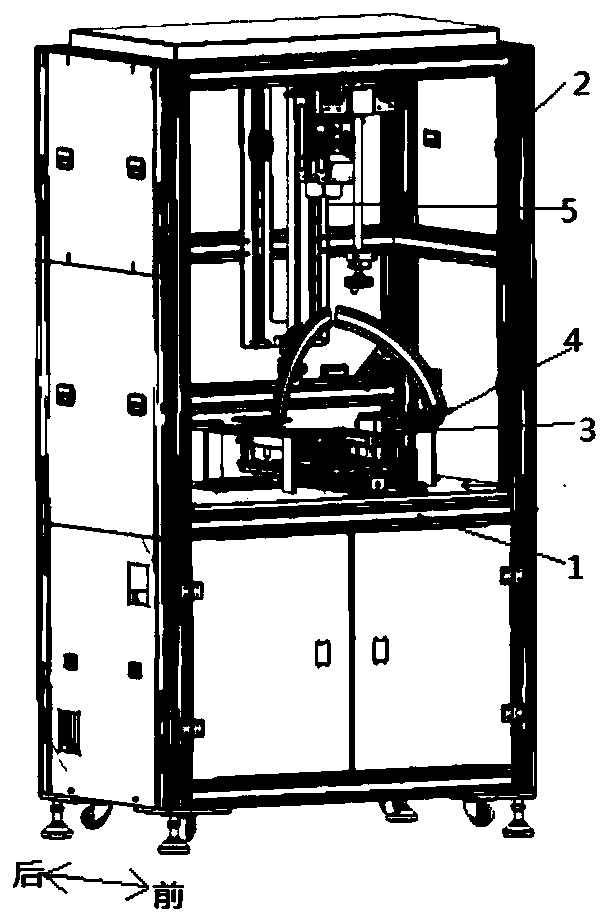

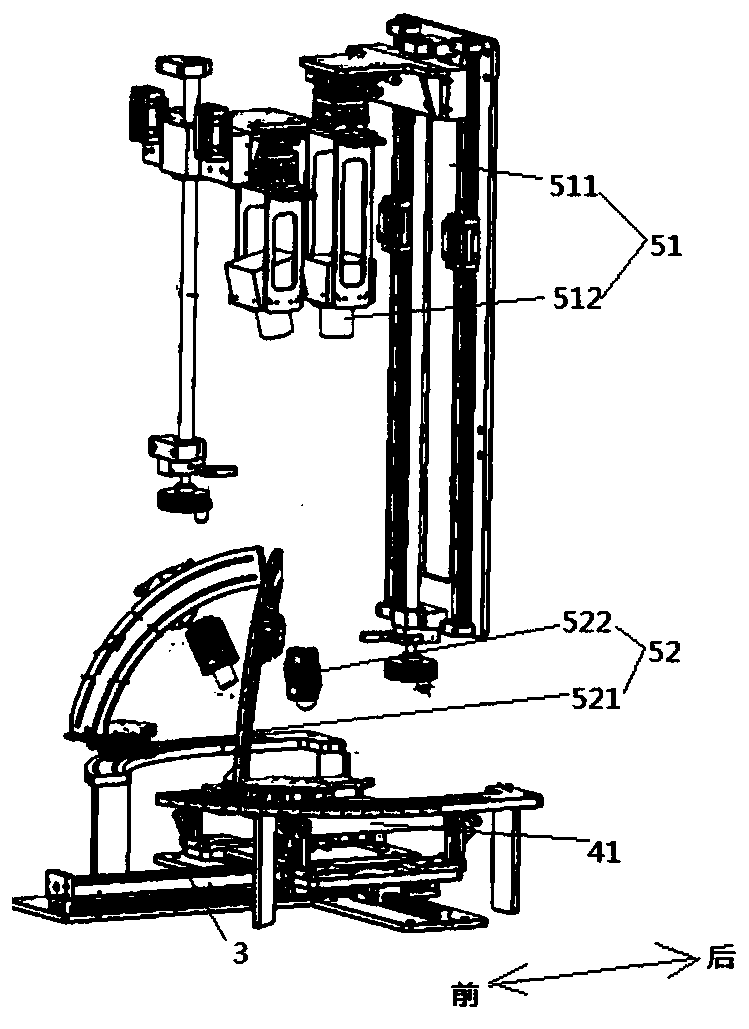

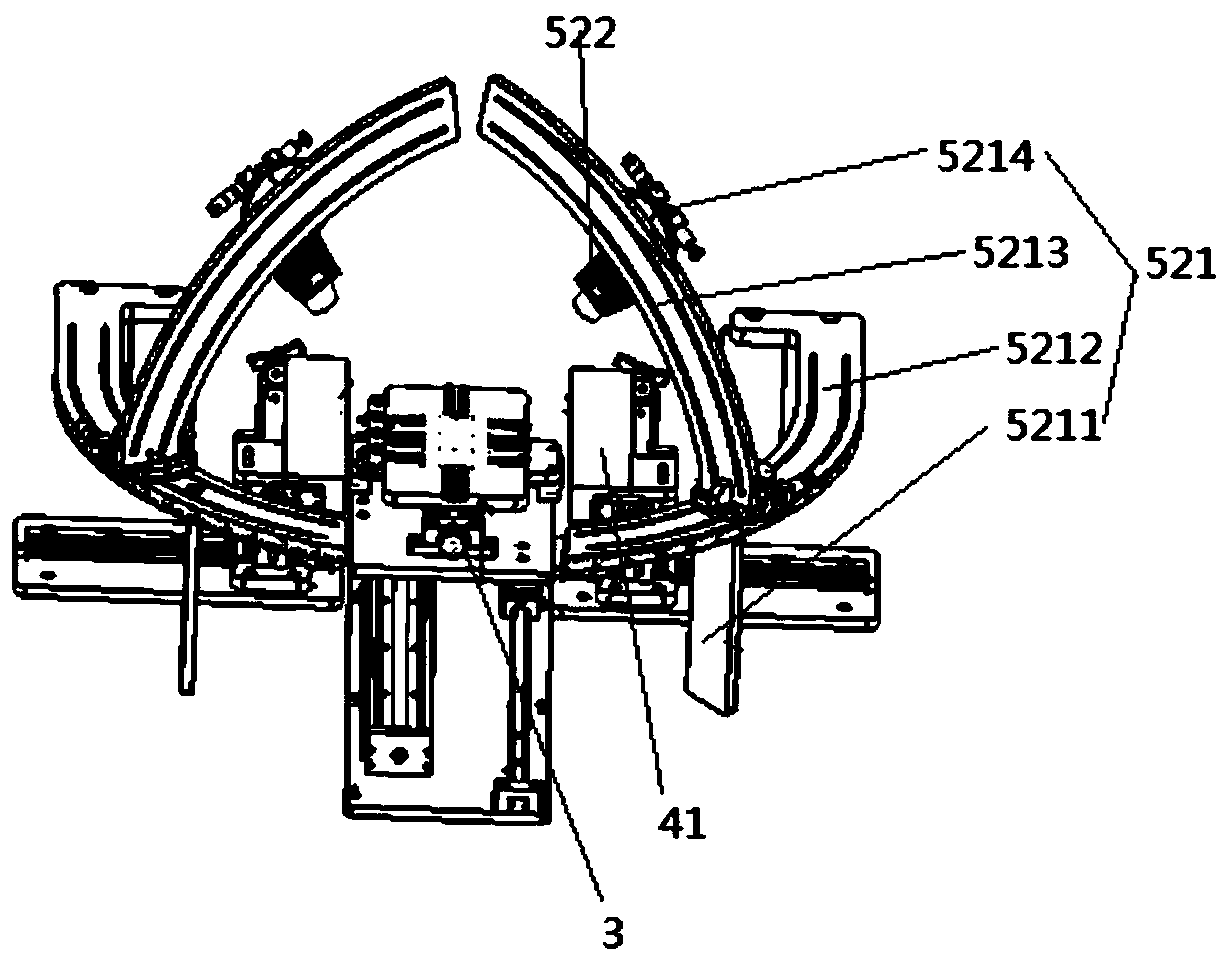

[0031] This embodiment provides an OLED panel display defect detection device, including a workbench 1, a black box cover 2, an object stage 3, a light source assembly 4, a camera assembly 5 and an image analysis device, and the black box cover 2 is set on the The top of the workbench is surrounded to form a light-tight chamber, and the dark box cover 2 is provided with a door that can be opened or closed, and the object table 3, light source assembly 4 and camera assembly 5 are all placed In the chamber, the image analysis device is arranged inside or outside the chamber, and the camera assembly 5 is electrically connected to the image analysis device, and the stage 3 is used to horizontally place the OLED panel to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com