A rapid cooling recovery device for reaction solvent

A technology of rapid cooling and reaction solvent, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as incomplete cooling and recovery, and achieve the effect of improving cooling effect, recycling water source, and improving cooling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

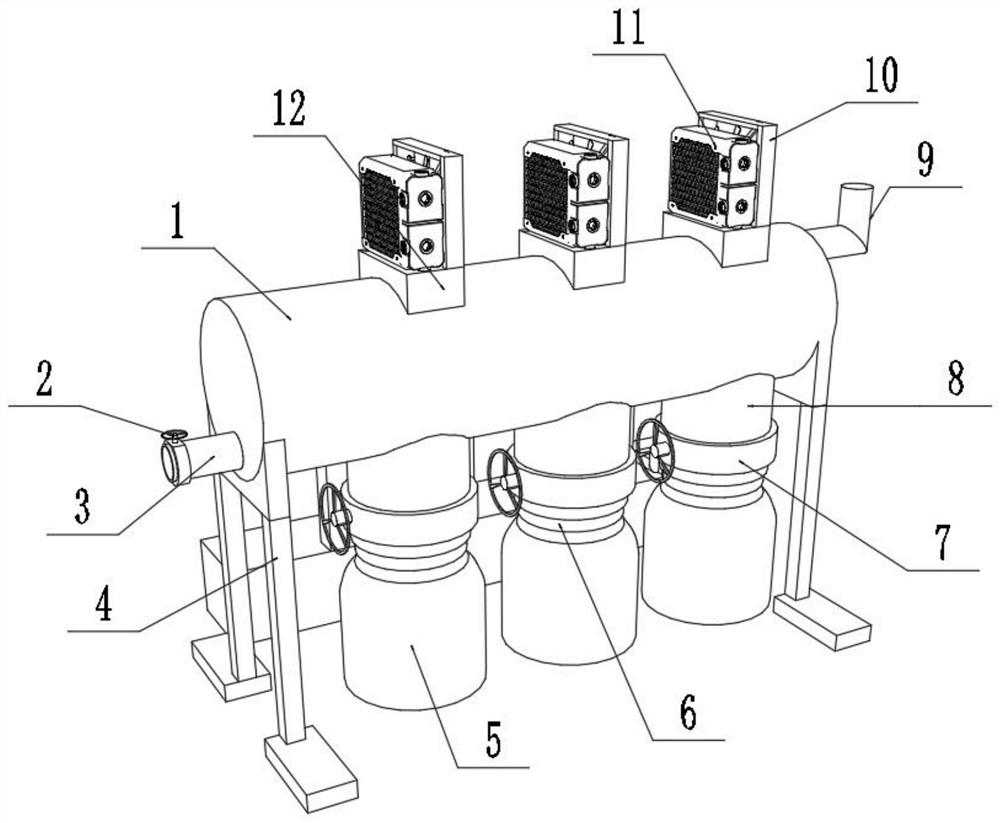

[0028] A reaction solvent rapid cooling recovery device, such as Figure 1-4 As shown, including the tank body 1 and the water tank 20, both sides of the bottom end of the tank body 1 are welded with brackets 4;

[0029] The bottom of one end of the tank body 1 is welded with an air inlet pipe 3, and the top of the other end of the tank body 1 is welded with an exhaust pipe 9. The outer wall of the air inlet pipe 3 is clamped with a first valve 2 through a clamp, and the air inlet pipe 3 is connected to a solvent-containing The chemical gas is discharged through the exhaust pipe 9 after cooling and recovery;

[0030] Wherein, the bottom end of the bottom of the tank body 1 is welded with several feeding pipes 8, the outer wall of the feeding pipe 8 is clamped with a second valve 7 through a clamp, and the bottom end of the feeding pipe 8 is welded with a connector 6, The bottom end of the connector 6 is threadedly connected to the collection tank 5; the tank body 1 is provide...

Embodiment 2

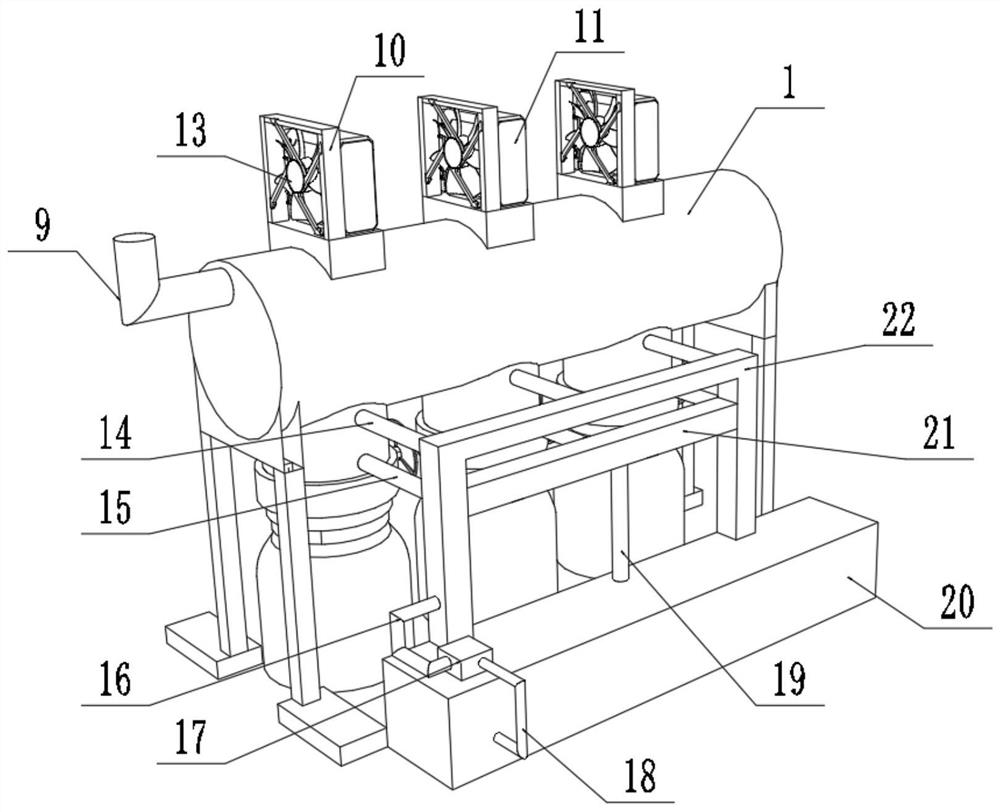

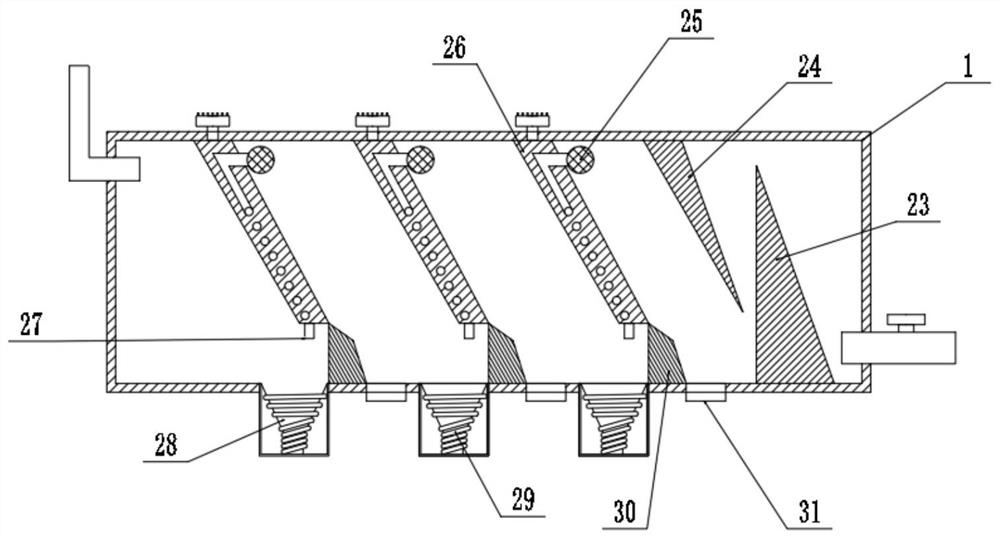

[0036] A reaction solvent rapid cooling recovery device, such as figure 2 and image 3 As shown, in order to solve the problem of incomplete cooling; this embodiment makes the following improvements on the basis of embodiment 1: the top of the water tank 20 is provided with a water-cooled driving mechanism, and a bucket body 28 is welded in the feeding pipe 8, and the bucket The outer wall of the body 28 is connected with a spirally distributed condensation pipe 29, and the solvent cooled by the drop pipe 27 is dropped into the bucket body 28 and discharged into the collection tank 5;

[0037] Wherein, the water-cooled drive mechanism includes a water tank 20, a gantry frame 22 and a water pump 17, the water pump 17 is fixed on the top of the water tank 20 by screws, the gantry frame 22 is welded to the top of the water tank 20, and the top of the condensation pipe 29 is welded with an outlet pipe 14, The bottom end of the condensation pipe 29 is welded with a water inlet pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com