Slow expansion type pre-crosslinked gel particle and preparation method thereof

A technology of gel particles and pre-crosslinking, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problem of enhanced expansion performance of pre-crosslinked gel particles, increased toxicity of pre-crosslinked gel particles, It is beneficial to protect the environment and other issues, and achieve the effect of reducing the entry speed, realizing the polymerization of aqueous solution, and improving the crosslinking strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

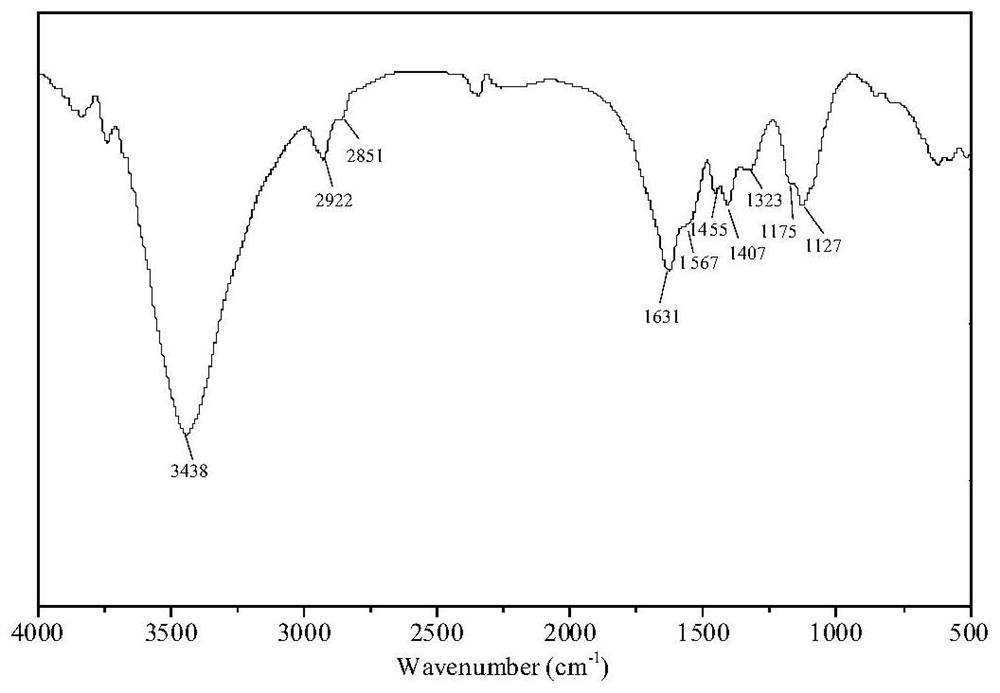

Method used

Image

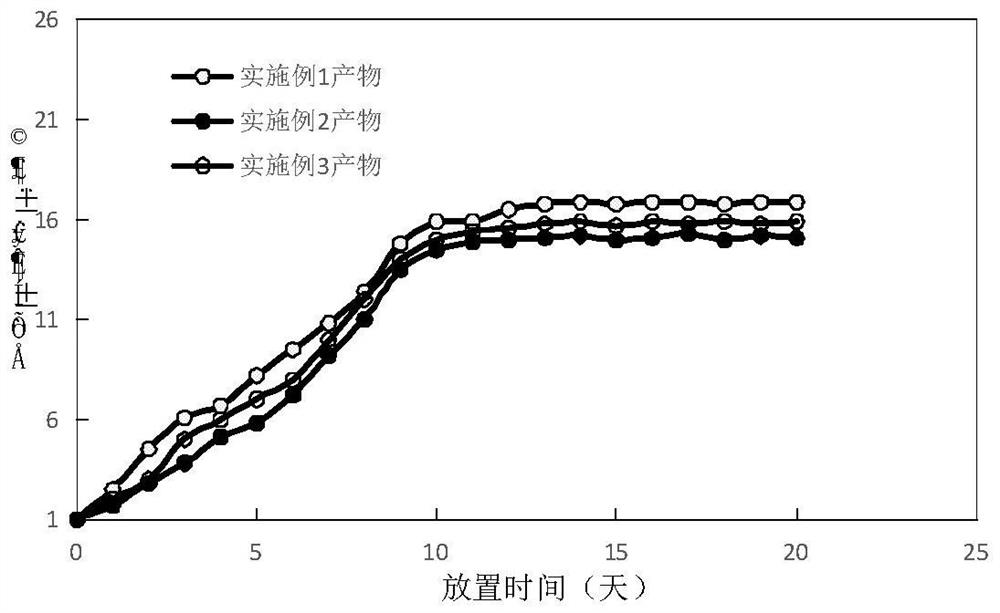

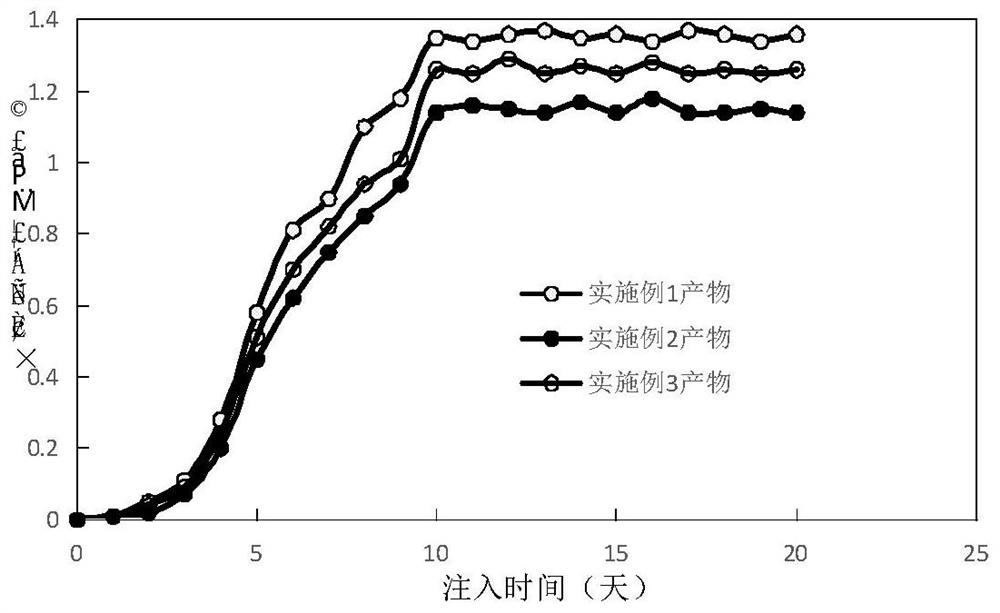

Examples

Embodiment 1

[0030] A slow-swelling pre-crosslinked gel particle is prepared from the following ingredients in parts by weight:

[0031] Acrylic acid 30g, sodium lauryl sulfate 0.15g, N,N'-methylenebisacrylamide 0.07g, 1,5-pentanediol diacrylate 0.12g, initiator 0.13g, pH adjuster, pH adjuster The dosage of the agent should meet the pH value requirement of the adjusted solution, and the balance of deionized water, the weight part of the pH regulator in this scheme is 16.65g.

[0032] The initiator is a redox system composed of an oxidizing agent and a reducing agent, preferably a sodium bisulfate-ammonium persulfate system; the pH regulator is sodium hydroxide.

[0033] A preparation method of slow-swelling type pre-crosslinked gel particles, comprising the following steps:

[0034] First, add 50g deionized water and 30g acrylic acid in the round bottom flask, adjust the pH with 16.65g sodium hydroxide, obtain the solution after adjusting the pH value;

[0035] Then, add 0.15g of sodium ...

Embodiment 2

[0039] A preparation method of slow-swelling type pre-crosslinked gel particles, comprising the following steps:

[0040] First, take the raw materials according to the following weight group distribution ratio:

[0041] Acrylic acid 25g, sodium lauryl sulfate 0.15g, N,N'-methylenebisacrylamide 0.09g, 1,5-pentanediol diacrylate 0.15g, initiator 0.16g, pH regulator 13.88g, Deionized water surplus; Wherein, initiator is sodium bisulfate-ammonium persulfate, and pH regulator is sodium hydroxide;

[0042] Then, add 50g deionized water and 25g acrylic acid in the round bottom flask, adjust pH with 13.88g sodium hydroxide, obtain the solution after adjusting the pH value;

[0043] Then, add 0.15g sodium lauryl sulfate, 0.09g N,N'-methylene bisacrylamide, 0.15g 1,5-pentanediol diacrylate to the solution obtained after adjusting the pH value, and stir thoroughly Supplementary adding deionized water is made into the aqueous solution that the mass concentration of acrylic acid is 25%; ...

Embodiment 3

[0047] 28g of acrylic acid, 0.14g of sodium lauryl sulfate, 0.08g of N,N'-methylenebisacrylamide, 0.13g of 1,5-pentanediol diacrylate, 0.12g of initiator, 15.55g of pH regulator, Deionized water balance.

[0048] In this scheme, the initiator is a redox system composed of an oxidizing agent and a reducing agent, preferably a sodium bisulfate-ammonium persulfate system; the pH regulator is sodium hydroxide.

[0049] A preparation method of slow-swelling type pre-crosslinked gel particles, comprising the following steps:

[0050] First, add 50g deionized water and 28g acrylic acid in the round bottom flask, adjust the pH with 15.55g sodium hydroxide, obtain the solution after adjusting the pH value;

[0051] Then, add 0.14g of sodium lauryl sulfate, 0.08g of N,N'-methylenebisacrylamide, 0.13g of 1,5-pentanediol diacrylate to the solution obtained after adjusting the pH value, and add Add deionized water to make an aqueous solution with a mass concentration of acrylic acid of 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com