Polymer micro-emulsion adopting gemini sulfonate type composite emulsifier, profile control and flooding system, and preparation method and application of polymer micro-emulsion

A technology of polymers and microemulsions, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problem of reduced oil displacement effect, poor oil-water interface activity, aquatic toxicity, skin irritation, poor teratogenicity and biodegradation sexual issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

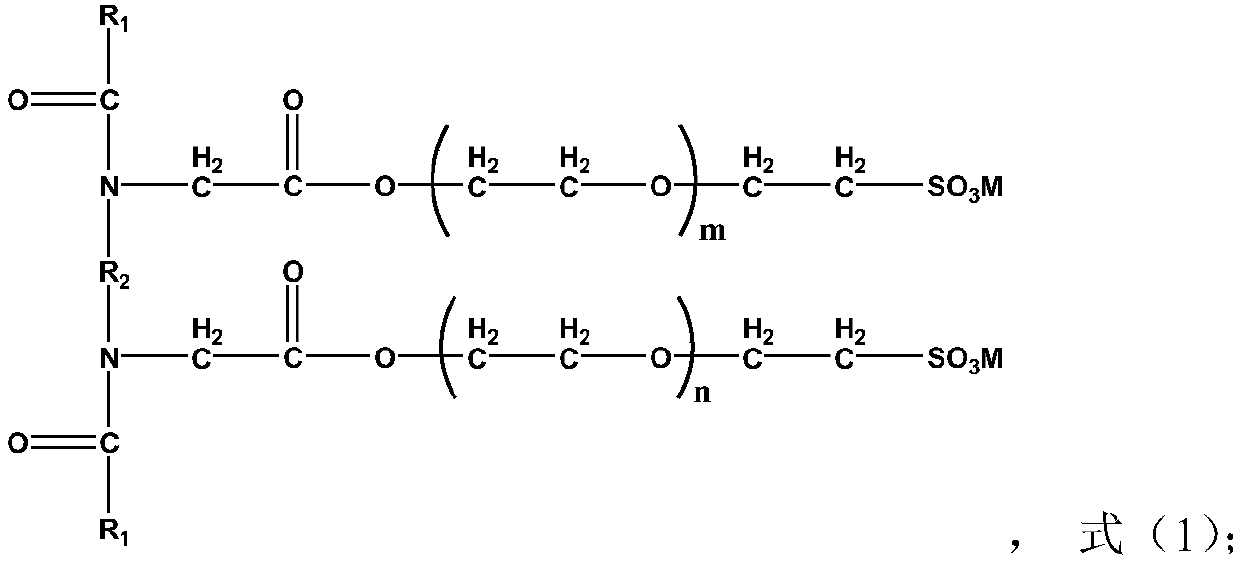

[0056] Preparation of N, N-dilauroyl ethylenediamine diacetic acid dipolyoxyethylene ether (m+n=6) disulfonate surfactant:

[0057] (a) Synthesis of two lauryl (lauroyl) ethylenediamine

[0058] Add 300g (1.5mol) of lauric acid, 267.8g (2.25mol) of thionyl chloride and 4.5g of DMF (0.06mol) into a 2000mL four-necked flask equipped with a sealed mechanical stirrer, a thermometer, a condenser, etc., and react at 80°C After 3 hours, excess thionyl chloride was distilled off under reduced pressure to obtain lauroyl chloride. When the temperature drops to 60°C, add 150g of dry toluene, stir evenly, slowly add dropwise the composition consisting of 30.0g (0.5mol) of anhydrous ethylenediamine, 99.0g (1.25mol) of anhydrous pyridine and 150g of dry toluene The mixed solution, the temperature is controlled to be less than 60°C, and the temperature is raised to 85°C for 2 hours after the dropwise completion. After cooling and filtering, the crude product was recrystallized from ethanol...

Embodiment 2

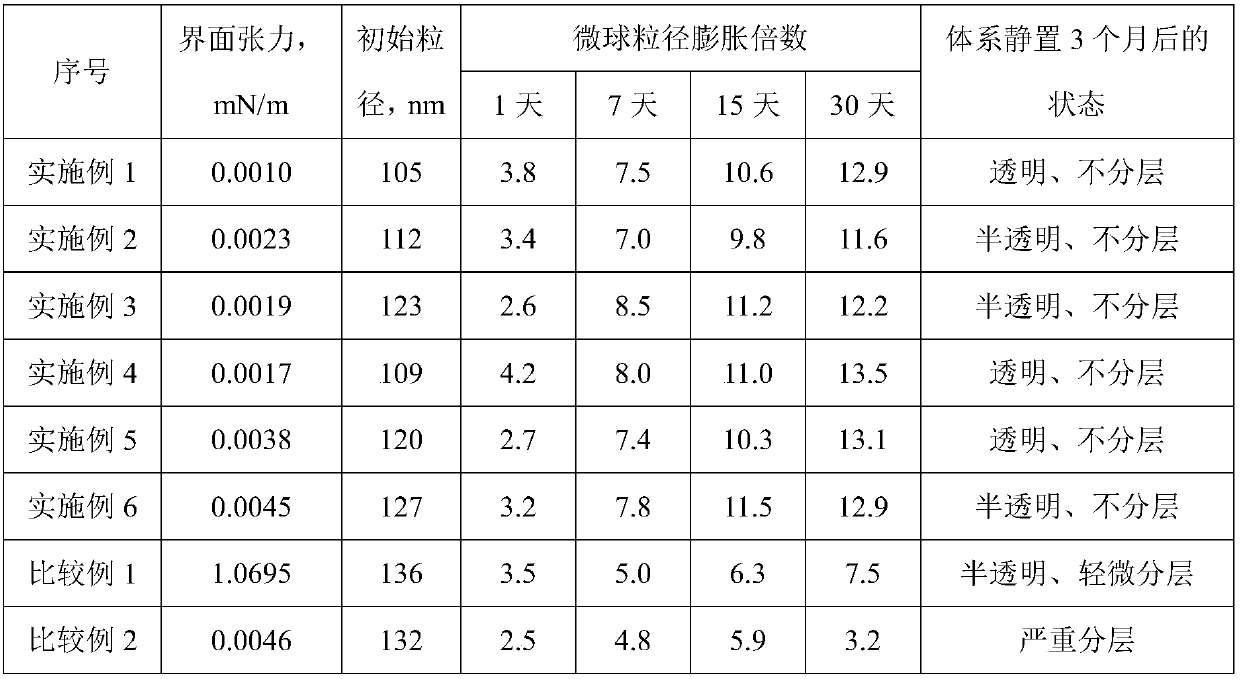

[0075] The preparation of N,N-dilauroyl ethylenediamine diacetic acid dipolyoxyethylene ether (m+n=6) sodium disulfonate surfactant and the preparation process of the polymer microemulsion control and flooding system are the same as [implementation Example 1], but the amount of emulsifier N, N-dilauroyl ethylenediamine diacetic acid dipolyoxyethylene ether (m+n=6) sodium bissulfonate and Tween80 were changed to 8g and 10g respectively. The polymer microemulsion control and flooding system and the characterization method of the polymer microspheres in it are the same as [Example 1], and the results are shown in Table 1.

Embodiment 3

[0077] The preparation of N,N-dilauroyl ethylenediamine diacetic acid dipolyoxyethylene ether (m+n=6) sodium disulfonate surfactant and the preparation process of the polymer microemulsion control and flooding system are the same as [implementation Example 1], but the amount of emulsifier N,N-dilauroyl ethylenediamine diacetic acid dipolyoxyethylene ether (m+n=6) sodium bissulfonate and Tween80 were changed to 10g and 8g respectively. The polymer microemulsion control and flooding system and the characterization method of the polymer microspheres in it are the same as [Example 1], and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com