Deslagging device of venturi cyclone dust collector

A cyclone dust collector and Venturi technology, applied in the field of Venturi cyclone dust collector, can solve the problems of high sealing requirements and difficult slag cleaning, and achieve the effect of increasing pipeline life and reducing scouring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The technical solution in one embodiment of the present invention will be described below with reference to the drawings in the embodiments of the present invention.

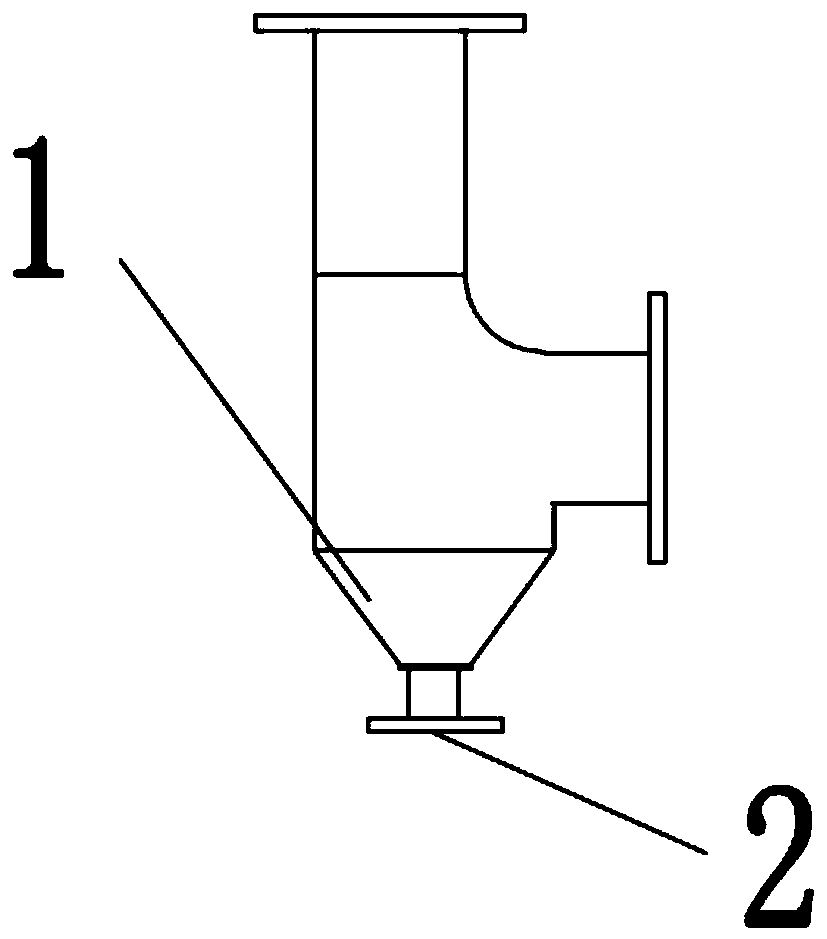

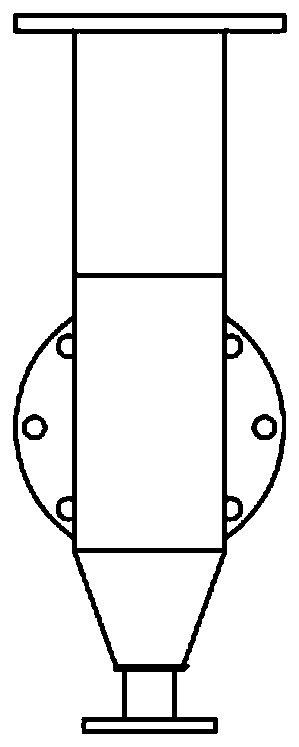

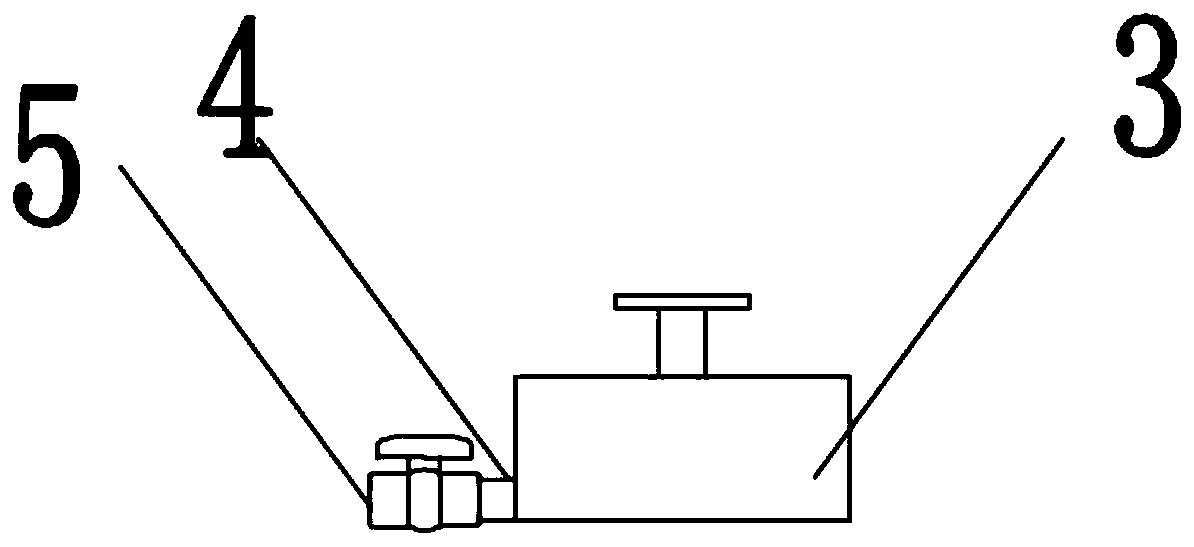

[0013] Such as figure 1 , 2 As shown in . The funnel 1 is composed of a rectangle and a truss structure, which is arranged at the rear end of the Venturi tube diffusion section, the cuboid and the truss are welded, the length, width and height of the cuboid are 250×150×50mm, and the size of the upper bottom of the truss is 250×150mm. The size of the lower bottom is 70×70mm, the height of the truss is 100mm, and the bottom of the cuboid is welded to the upper bottom of the truss; the flapper valve is set on the pipeline behind the slag outlet 2 of the funnel to control the removal of slag liquid and the The diameter of the pipe is DN50; the slag liquid tank 3 is connected behind the flapper valve, the slag liquid tank 3 is a cuboid structure with a length, width and height of 350×350×150 mm, and a sewage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com