Circuit board surface cleaning device

A surface cleaning device and a technology for circuit boards, which are used in the cleaning/polishing of conductive patterns, cleaning methods and utensils, secondary processing of printed circuits, etc. problems, to achieve the effect of easy maintenance, improved service life and good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

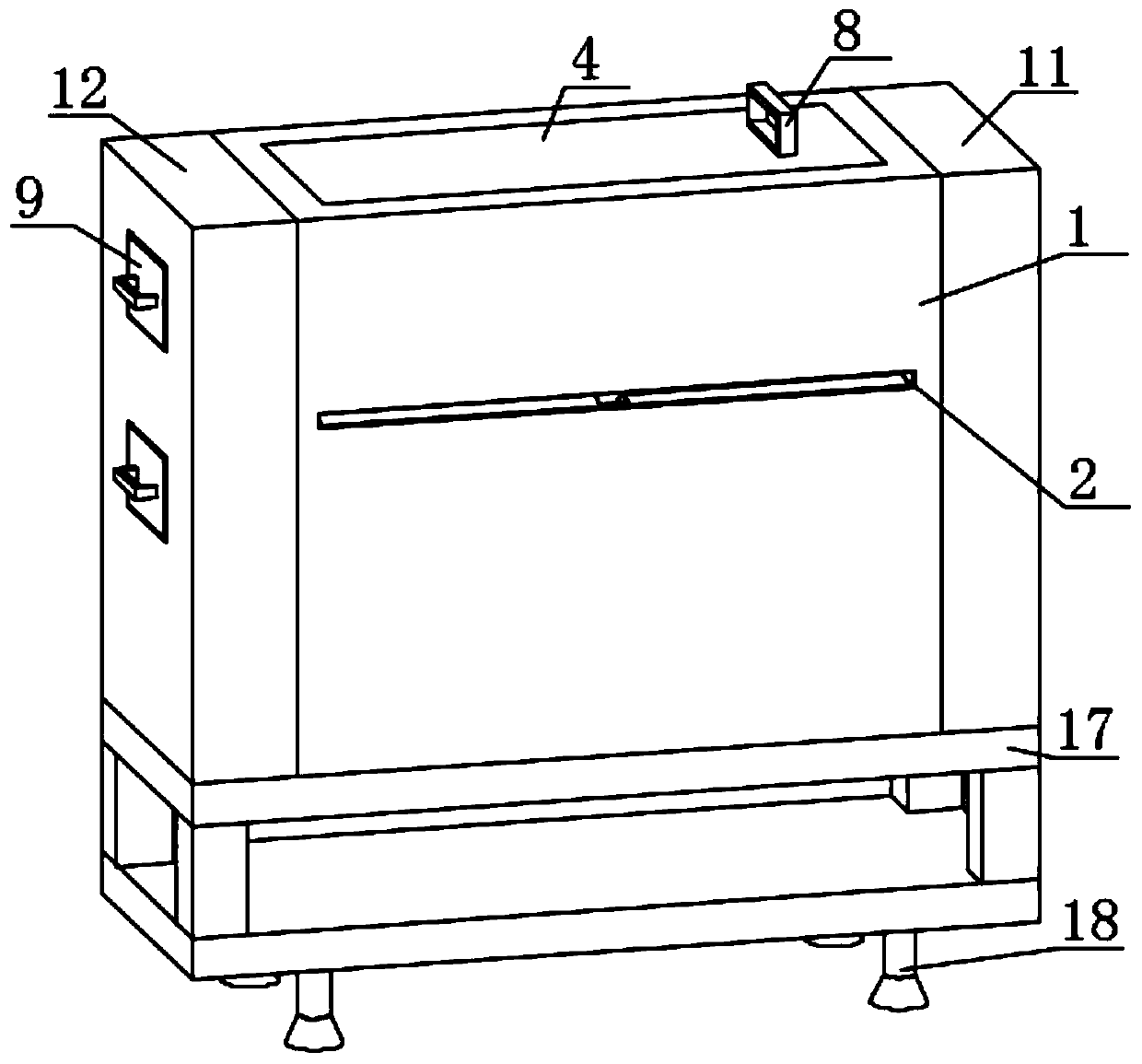

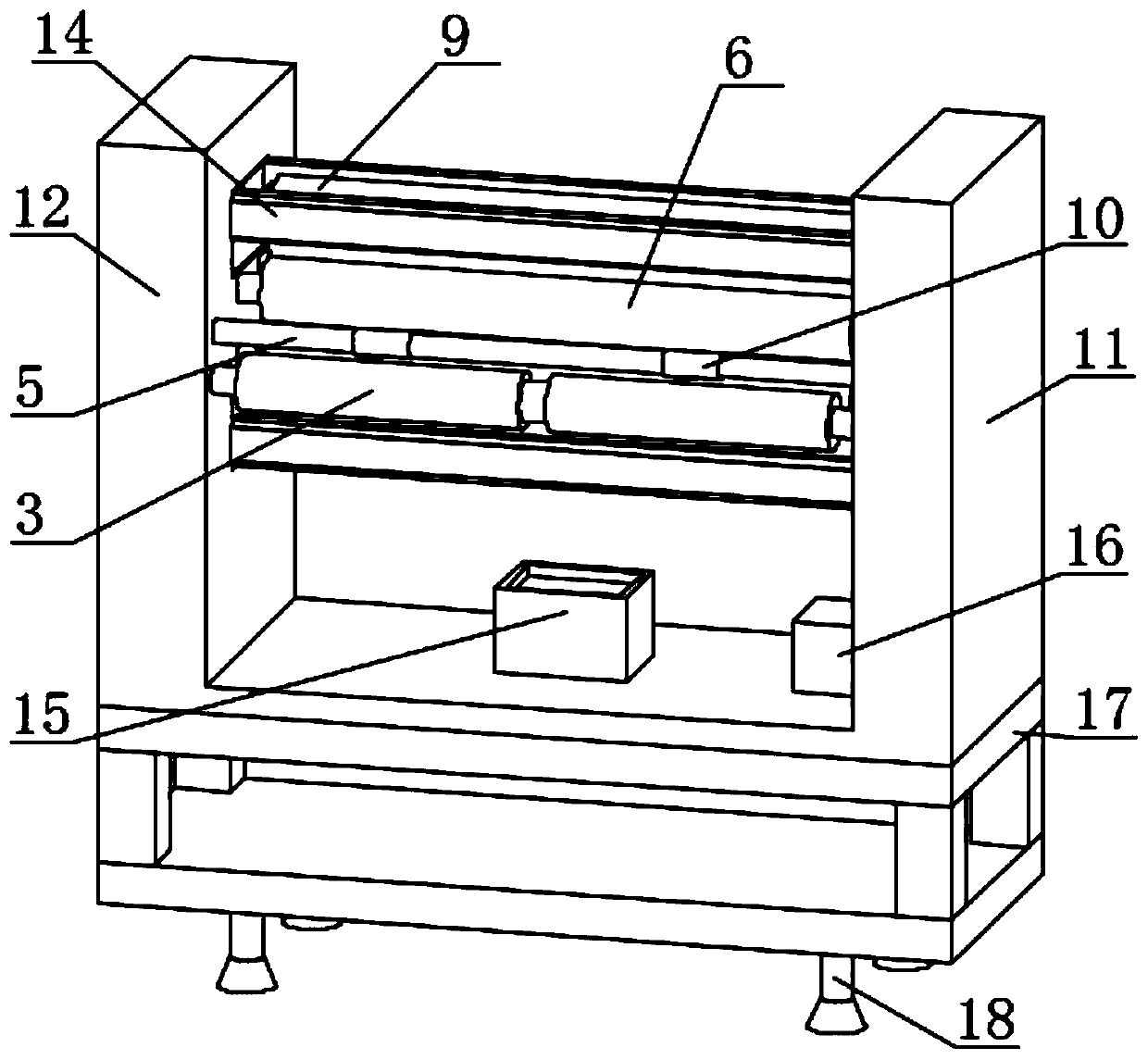

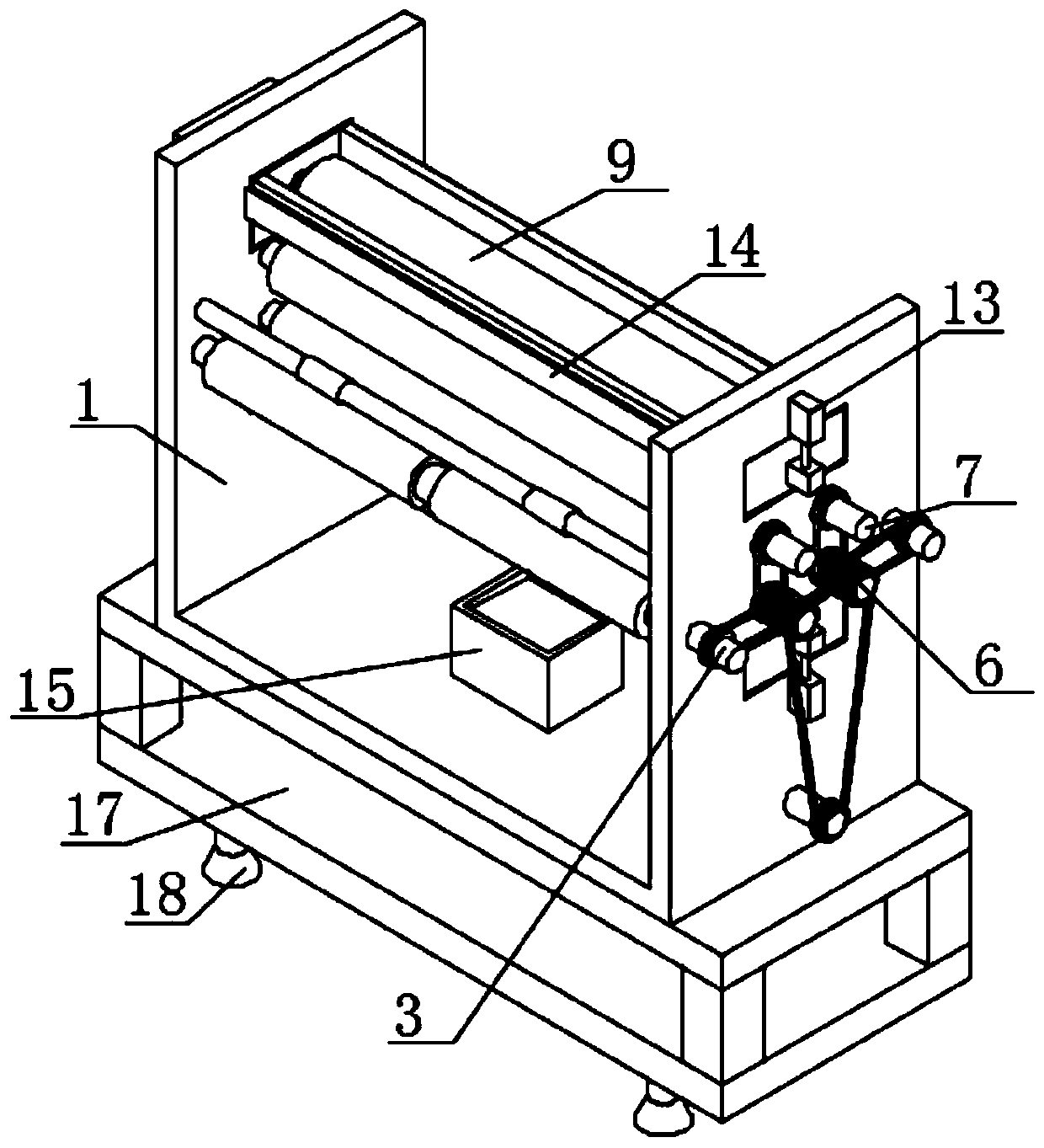

[0022] Such as Figure 1-4 As shown, the embodiment of the present invention provides a circuit board surface cleaning device, including a cleaning box 1, both sides of the cleaning box 1 are provided with access grooves 2, and one side of the inner bottom wall of the cleaning box 1 is fixedly connected with a variable speed motor 16, The variable-speed motor 16 of the present invention uses a 1300W variable-speed motor, and both sides of the cleaning box 1 are connected with feed rollers 3 in rotation, and the inside of the cleaning box 1 is fixedly connected with two symmetrical nip rolls 5, two nip rolls 5 They are respectively located directly above the two feed rollers 3, and the outer surfaces of the two nip rollers 5 are fixedly connected with pressure blocks 10. The board is limited and compacted to avoid the circuit board from being stuck on the feeding roller 3. The upper end of the cleaning box 1 is rotatably connected with two symmetrical upper ash rollers 7, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com