Welding table suitable for processing metal pipes and metal plates

A metal plate and welding table technology, which is applied in metal processing, welding equipment, auxiliary welding equipment, etc., can solve the problems of high processing difficulty and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

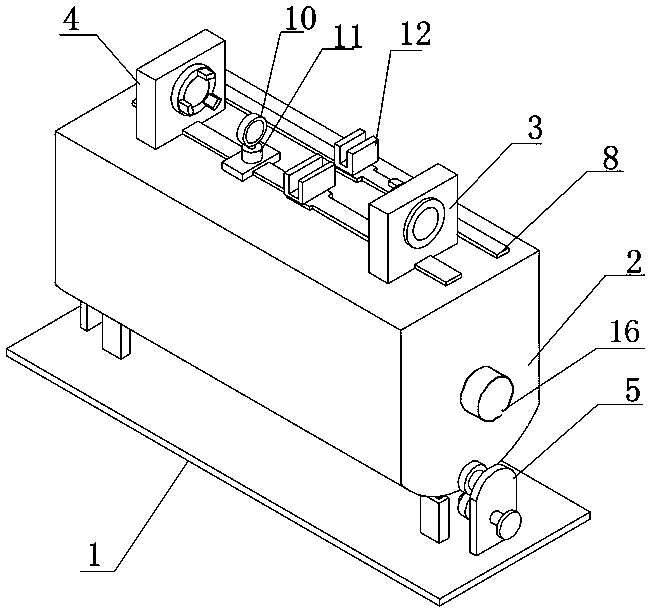

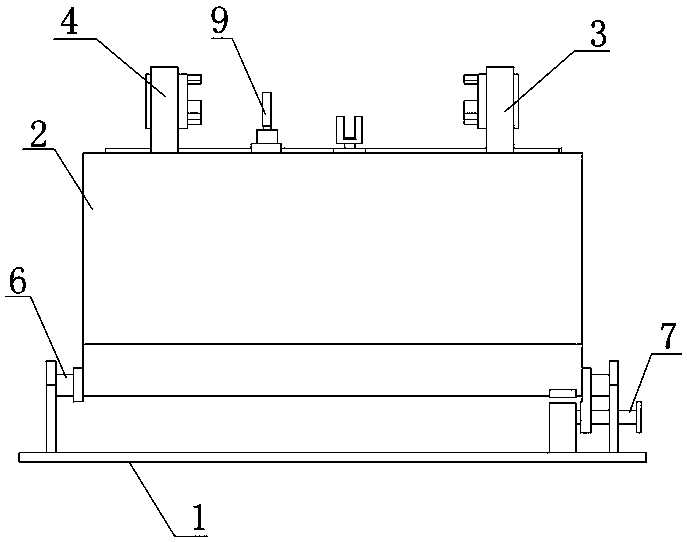

[0032]As shown in the figure: the embodiment of the present invention provides a welding table suitable for processing metal pipes and metal plates. The processing table 2 is arranged on the base 1. The base 1 includes a supporting bottom and two supporting arms 5 with threaded mounting holes. , the bottom of the support is provided with rollers, the bottom surface of the processing table 2 is arc-shaped, and mounting studs 6 are fixed on both sides of the bottom surface. Gears are also fixed on the column 6, and an adjustment rod 7 is pierced below the threaded mounting hole of a support arm 5, and the part of the adjustment rod 7 located between the two support arms 5 is fixed with a gear meshed with the gear of the installation stud 6, The other end is provided with an adjustment disc for convenient rotation of the adjusting rod 7, and the bottom of the processing table 2 is symmetrically provided with a restricting table with the mounting studs 6, and a clamping table is pr...

Embodiment 2

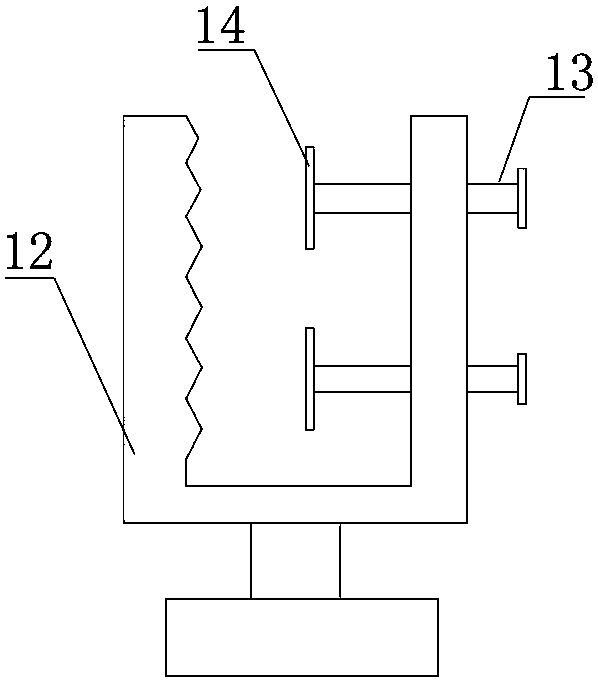

[0037] On the basis of Embodiment 1, the structure of this scheme is further optimized. In this scheme, the top of the processing table 2 is open and a processing plate 20 is installed through a plurality of cross bars. The processing plate 20 is parallel to the upper surface of the processing table 2 Opening, the length and width of the processing plate 20 are all smaller than the length and width of the top surface of the processing table 2, so that there is a gap between the four sides of the top surface of the processing table 2 and the four edges of the processing plate 20 to facilitate the falling of waste materials, and the processing plate The four edges of 20 are provided with folded edges that are bent downward in the inner cavity of processing table 2, which facilitates the cleaning of processing plate 20. A waste material collection mechanism is also provided inside the processing table 2. The waste material collection mechanism includes a vibrating screen plate 15 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com