Rotary grillage machine

A grid machine and rotary technology, applied in water/sludge/sewage treatment, mobile filter element filter, filtration separation, etc., can solve problems such as easy to be entangled by debris, impurity odor, difficult to clean, etc., to achieve Good decontamination effect, guaranteed normal work, guaranteed decontamination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

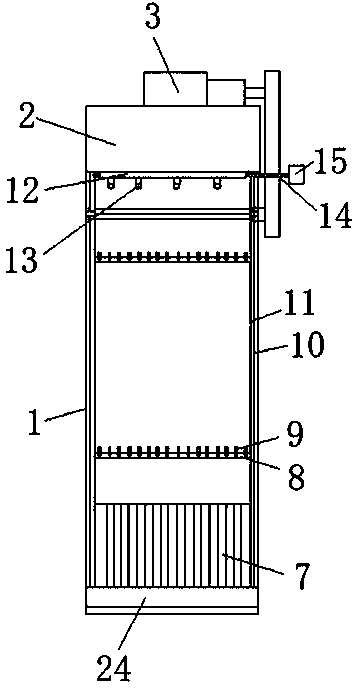

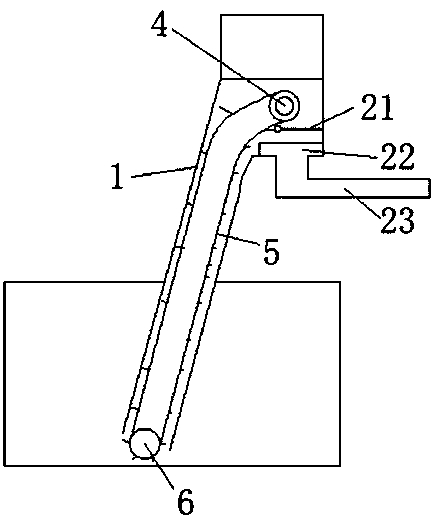

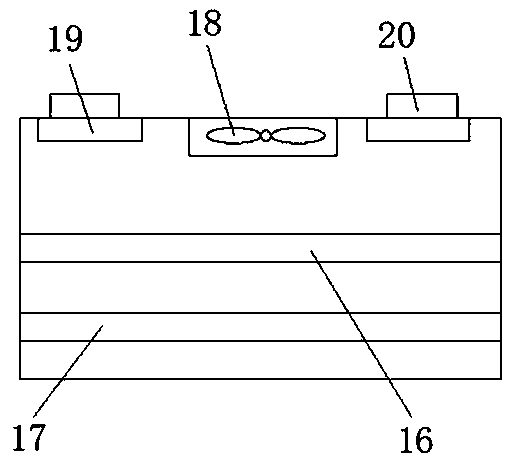

[0019] Such as Figure 1-3 As shown, a rotary grille machine includes a frame 1, a purification box 2 is arranged above the frame 1, a motor 3 is arranged above the purification box 2, and one end of the motor 3 is connected to the No. 1 sprocket with a belt 4, and the No. 1 sprocket 4 is located above the interior of the frame 1. The No. 1 sprocket 4 is connected to the No. 2 sprocket 6 through the traction chain 5. A grid 7 is arranged on the inner side of the traction chain 5. The grid A tooth rake 8 is arranged above the bar 7, and the surface of the tooth rake 8 is fixedly connected to the tooth head 9. Slide rails 11 are arranged on both sides of the inside of the frame 1, and one side of the slide rail 11 is slidingly connected to a cross b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com