Cementitious material containing waste incineration fly ash and steel slag slag, preparation method and application

A waste incineration fly ash and cementitious material technology, which is applied in the field of building materials, can solve the problems of adding too much activator, etc., and achieve the effects of improving recycling rate, high compressive strength, leaching safety, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] A high-aluminum steel slag-slag-fly ash-desulfurized gypsum solidified heavy metal cementitious material of this embodiment is mainly composed of the following components in mass percentage: 40% of S95 slag powder, 20% of high-alumina steel slag powder, and 30% of waste incineration fly ash , Desulfurization gypsum 10%.

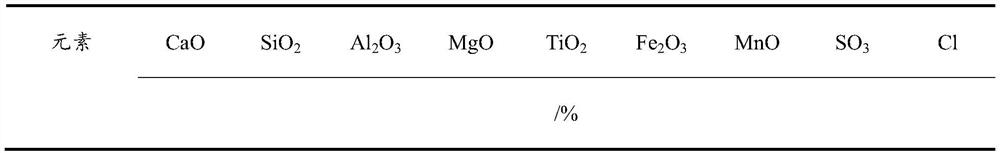

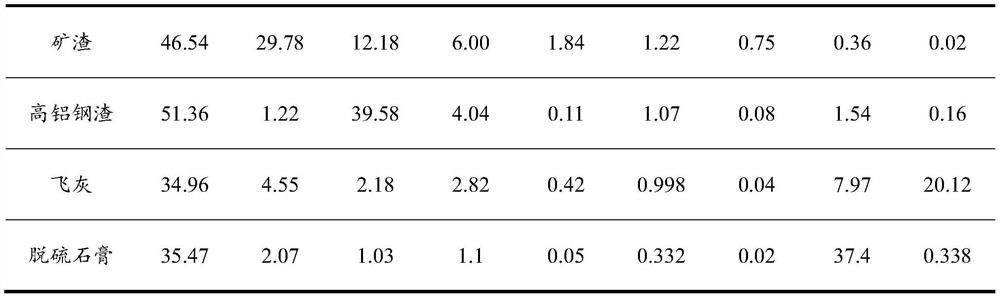

[0057] Among them, the chemical compositions of S95 slag powder, fly ash, high-alumina steel slag and desulfurized gypsum are shown in Table 1.

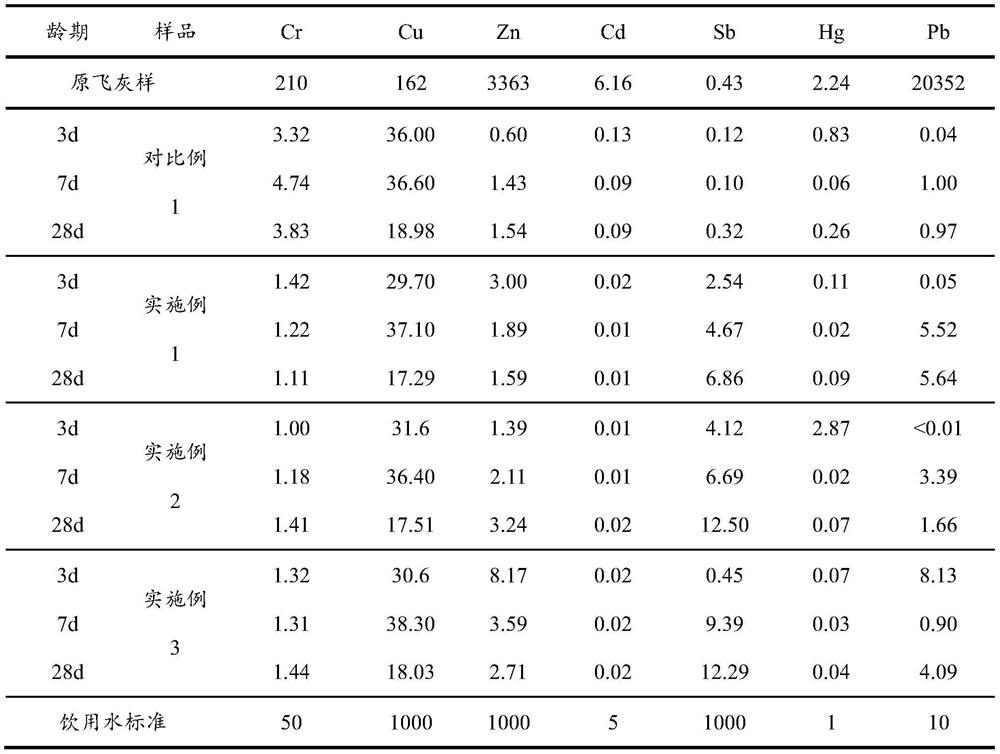

[0058] After pouring and molding, it was maintained to different ages for leaching toxicity testing. The test method was the same as that of Comparative Example 1. The test results are shown in Table 2.

Embodiment 2

[0060] The preparation method of a high-alumina steel slag-slag-fly ash-desulfurized gypsum solidified heavy metal cementitious material in this embodiment mainly consists of the following components in mass percentage: S95 slag powder 20%, high-alumina steel slag powder 40%, garbage Incineration fly ash 30%, desulfurization gypsum 10%.

[0061] Among them, the chemical compositions of S95 slag powder, fly ash, high-alumina steel slag and desulfurized gypsum are shown in Table 1.

[0062] After pouring and molding, it was maintained to different ages for leaching toxicity testing. The test method was the same as that of Comparative Example 1. The test results are shown in Table 2.

Embodiment 3

[0064] The preparation method of a high-alumina steel slag-slag-fly ash-desulfurized gypsum solidified heavy metal cementitious material in this embodiment is mainly composed of the following components in terms of mass percentages: high-alumina steel slag powder 60%, waste incineration fly ash 30% %, desulfurized gypsum 10%.

[0065] Among them, the chemical compositions of fly ash, high aluminum steel slag and desulfurized gypsum are shown in Table 1.

[0066] After pouring and molding, it was maintained to different ages for leaching toxicity testing. The test method was the same as that of Comparative Example 1. The test results are shown in Table 2.

[0067] Table 1 Raw material chemical composition % analysis

[0068]

[0069]

[0070] Table 2 The leaching concentration of heavy metals in clean slurry test blocks of different ages (μg / L)

[0071]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com