Bottom slurry for light-transmitting ceramic tile and preparation method of bottom slurry

A technology of ceramic tiles and primer, which is applied in the field of ceramics, can solve the problems that the primer does not have light transmission, affects the appearance of light-transmitting bricks, and blocks the irradiation of light, so as to improve the suspension performance, improve the aesthetics, and eliminate the impact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

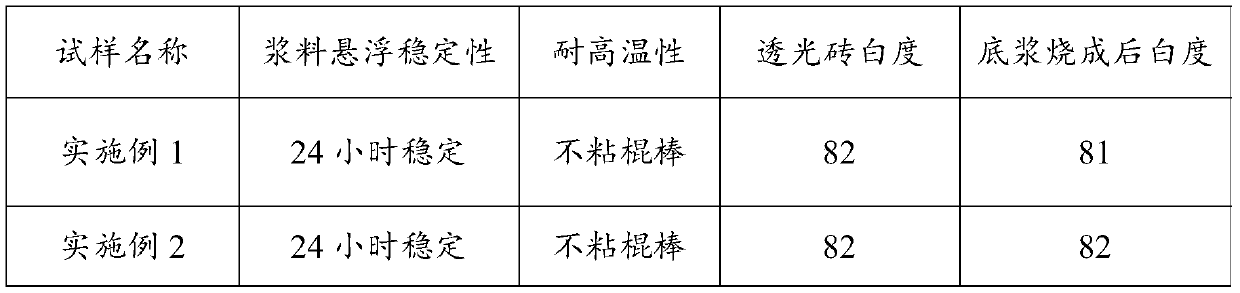

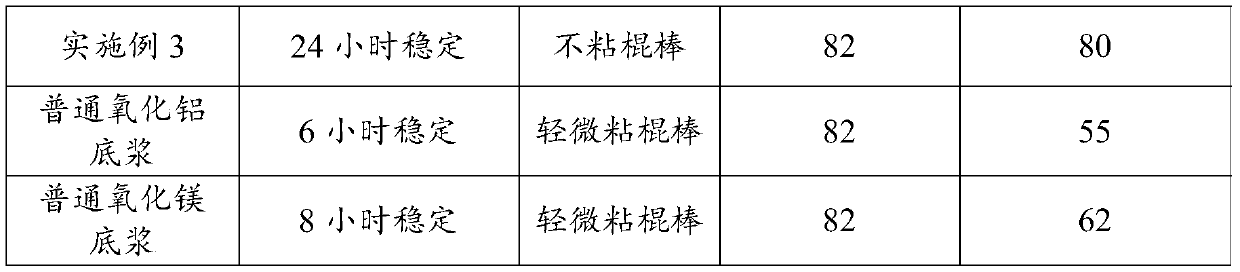

Embodiment 1

[0021] A primer for light-transmitting ceramic tiles, the raw materials and the added mass parts of the primer for light-transmitting ceramic tiles are: 30 parts of clay, 70 parts of anorthite and 0.5 parts of surfactant, wherein the surfactant It is made by mixing sodium polycarboxylate and sodium tripolyphosphate at a weight ratio of 1:1, and the content of iron oxide and titanium oxide in the clay is 0.45%.

[0022] A method for preparing a primer for light-transmitting ceramic tiles, wherein the specific operating steps are:

[0023] (1) Take by weighing 30 parts of clay, 70 parts of anorthite and 0.5 part of surfactant, place in a ball mill, then add a certain amount of water, mix and ball mill to obtain a slurry,

[0024] (2) The obtained slurry is discharged, and then iron removal treatment is carried out through an iron removal tank equipped with iron removal rods to obtain a base slurry for light-transmitting ceramic tiles, wherein the solid phase content of the slurr...

Embodiment 2

[0026] A primer for light-transmitting ceramic tiles, the raw materials and the added mass parts of the primer for light-transmitting ceramic tiles are: 10 parts of clay, 90 parts of anorthite and 2 parts of surfactant, wherein the surfactant It is made by mixing sodium polycarboxylate and sodium tripolyphosphate at a weight ratio of 3:1, and the content of iron oxide and titanium oxide in the clay is 0.35%.

[0027] A method for preparing a primer for light-transmitting ceramic tiles, wherein the specific operating steps are:

[0028] (1) Take by weighing 10 parts of clay, 90 parts of anorthite and 2 parts of surfactant, place in a ball mill, then add a certain amount of water, mix and ball mill to obtain a slurry,

[0029] (2) The obtained slurry is discharged, and then iron removal treatment is carried out through an iron removal tank equipped with iron removal rods to obtain a base slurry for light-transmitting ceramic tiles, wherein the solid phase content of the slurry i...

Embodiment 3

[0031] A primer for light-transmitting ceramic tiles, the raw materials and the added mass parts of the primer for light-transmitting ceramic tiles are: 20 parts of clay, 80 parts of anorthite and 1.5 parts of surfactant, wherein the surfactant It is made by mixing sodium polycarboxylate and sodium tripolyphosphate at a weight ratio of 2:1, and the content of iron oxide and titanium oxide in the clay is 0.48%.

[0032] A method for preparing a primer for light-transmitting ceramic tiles, wherein the specific operating steps are:

[0033] (1) Take by weighing 20 parts of clay, 80 parts of anorthite and 1.5 parts of surfactant, place in a ball mill, then add a certain amount of water, mix and ball mill to obtain a slurry,

[0034] (2) The obtained slurry is discharged, and then iron removal treatment is carried out through an iron removal tank equipped with iron removal rods to obtain a base slurry for light-transmitting ceramic tiles, wherein the solid phase content of the slur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com