Method for detecting consistency of furnace temperature of continuous heating furnace

A detection method and heating furnace technology, applied to heat treatment furnaces, furnaces, furnace types, etc., can solve the problem that the temperature detection method cannot accurately measure the temperature consistency of the heating furnace, and achieve the effect of accurate temperature consistency and good continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

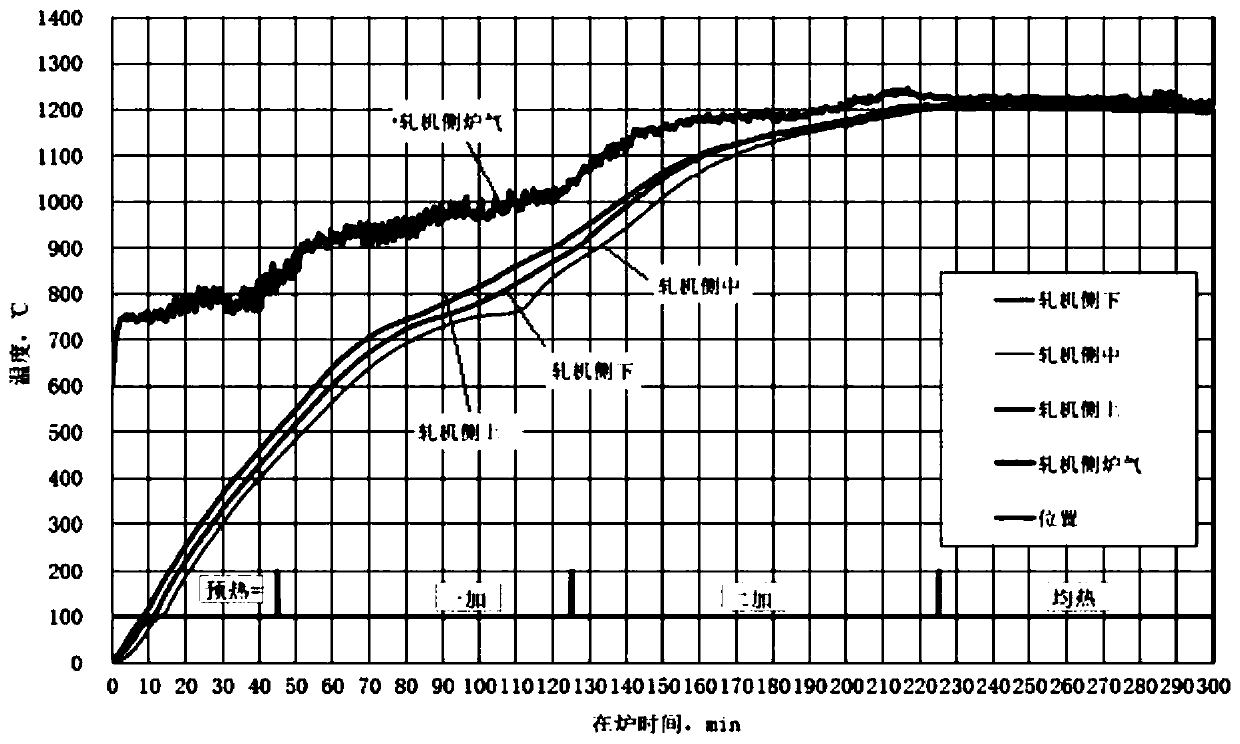

[0039] This embodiment provides a method for detecting the consistency of furnace temperature in a continuous heating furnace, comprising the following steps:

[0040] Step 1. Set the temperature test point:

[0041] In this embodiment, a bearing steel billet is used as the test billet. The bearing steel is a high-carbon steel with relatively poor thermal conductivity. There is a temperature difference between the internal and surface temperatures of the billet, which can better reflect the actual heating capacity and temperature consistency of the heating furnace.

[0042] The size of the test billet is based on the size of the hearth of the continuous heating furnace, which should be able to cover all heating areas, especially the length can reflect the heating effect of different positions in the furnace. The size of the test billet used in this example is 250mm*280mm*7270mm .

[0043] First, a total of 9 temperature measurement points are set up on the test billet. Selec...

Embodiment 2

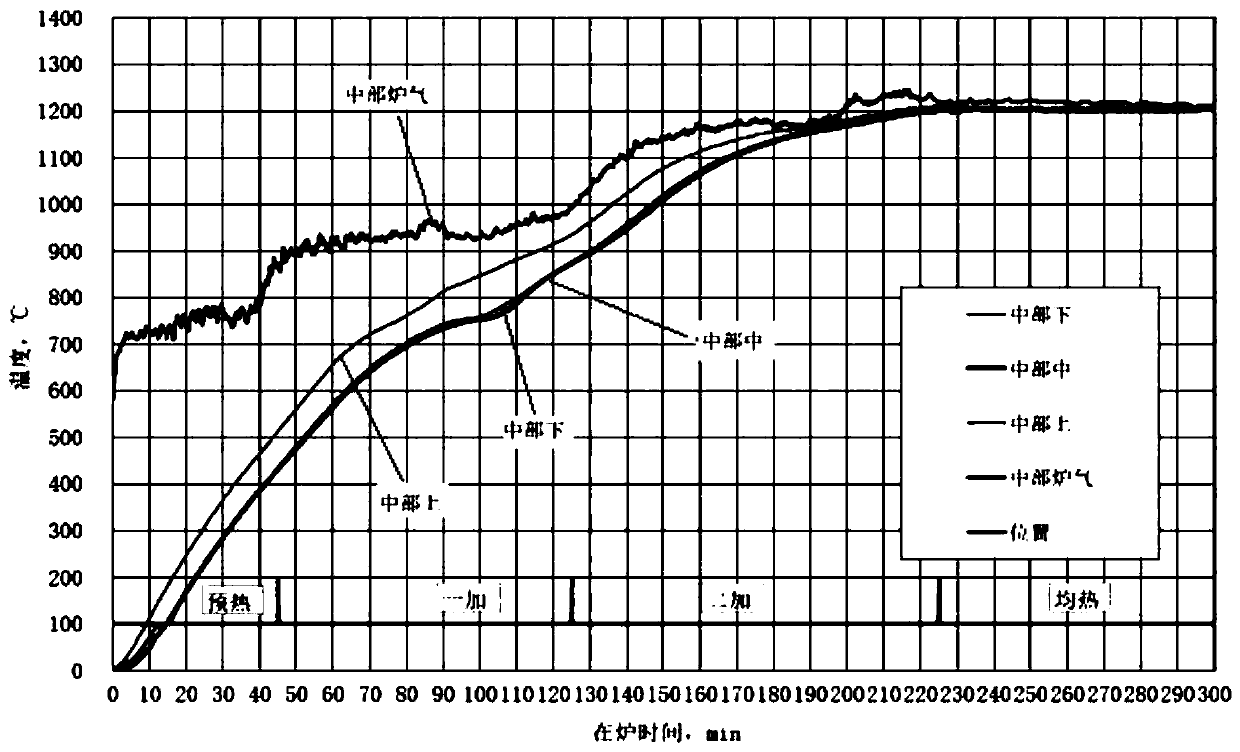

[0054] This embodiment provides a method for detecting the consistency of furnace temperature in a continuous heating furnace, comprising the following steps:

[0055] Step 1. Set the temperature test point:

[0056] In this embodiment, a bearing steel billet is used as the test billet. The bearing steel is a high-carbon steel with relatively poor thermal conductivity. There is a temperature difference between the internal and surface temperatures of the billet, which can better reflect the actual heating capacity and temperature consistency of the heating furnace.

[0057] The size of the test billet is based on the size of the hearth of the continuous heating furnace, which should be able to cover all heating areas, especially the length can reflect the heating effect of different positions in the furnace. The size of the test billet used in this example is 250mm*280mm*7270mm .

[0058] First, a total of 12 temperature measurement points are set on the test billet. Select ...

Embodiment 3

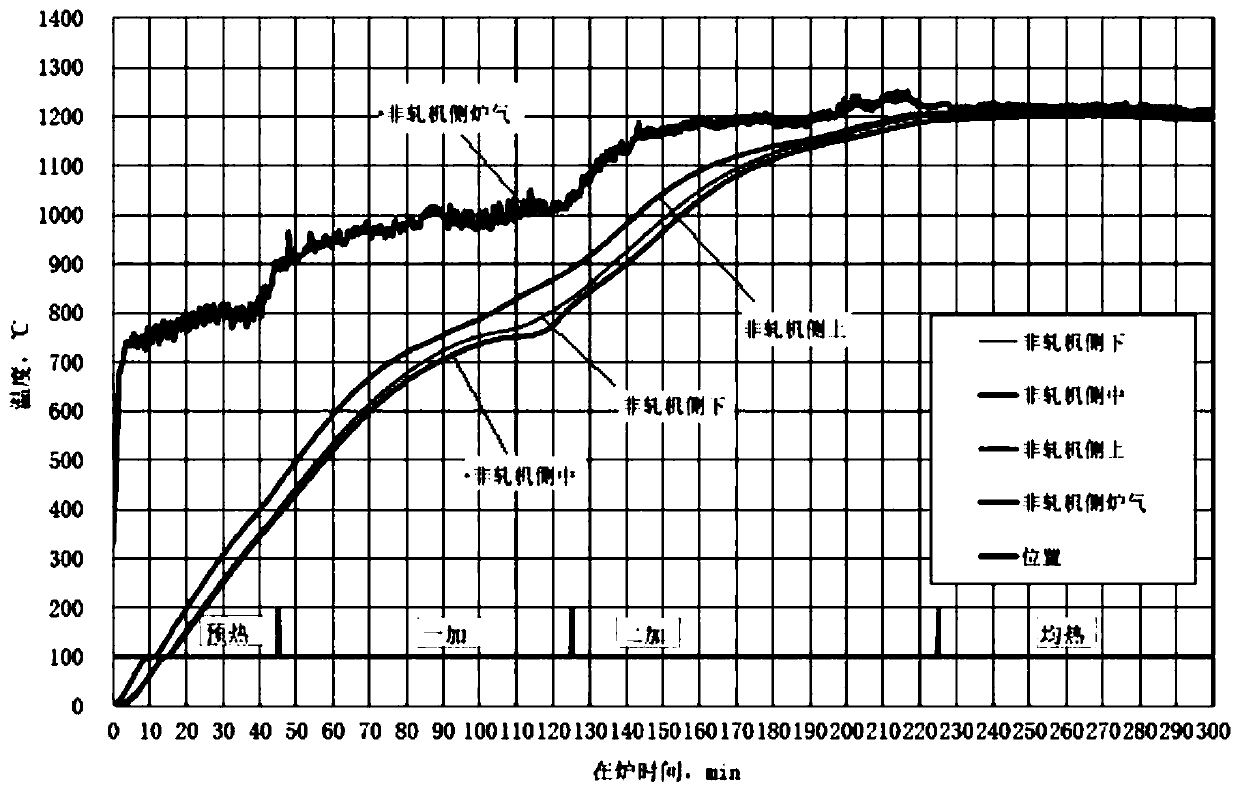

[0091] This embodiment provides a method for detecting the consistency of furnace temperature in a continuous heating furnace, comprising the following steps:

[0092] Step 1. Set the temperature test point:

[0093] In this embodiment, a bearing steel billet is used as the test billet. The bearing steel is a high-carbon steel with relatively poor thermal conductivity. There is a temperature difference between the internal and surface temperatures of the billet, which can better reflect the actual heating capacity and temperature consistency of the heating furnace.

[0094] The size of the test billet is based on the size of the hearth of the continuous heating furnace, which should be able to cover all heating areas, especially the length can reflect the heating effect of different positions in the furnace. The size of the test billet used in this example is 250mm*280mm*7270mm .

[0095] First, a total of 9 temperature measurement points are set up on the test billet. Selec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com