Dual-fuel ignition chamber type two-stroke engine based on reformed gas and combustion control method

A technology of ignition chamber and reformed gas, which is applied in engine control, combustion engine, internal combustion piston engine, etc. It can solve the problems of limiting engine performance improvement, difficult reliable control, and small working range, so as to improve ignition performance and clean it efficiently burning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

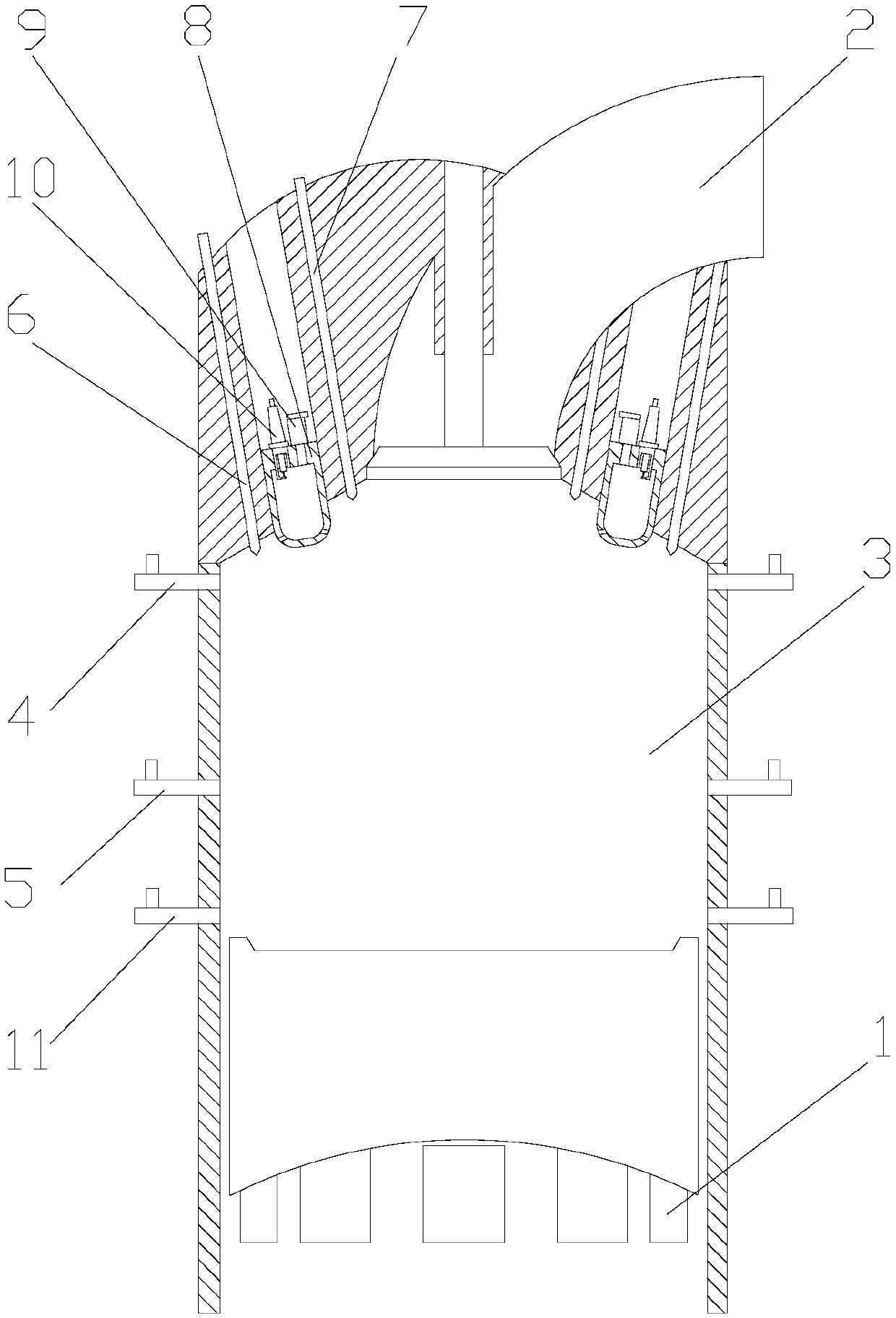

[0031] Such as figure 1As shown, the engine includes a scavenging port 1, an exhaust port 2 and a combustion chamber 3, and is characterized in that: the cylinder head first main fuel nozzle 6 is set on the cylinder head and / or the cylinder liner first main fuel nozzle 6 is set on the cylinder liner Nozzle 4, the second main fuel nozzle 7 of the cylinder head is set on the cylinder head and / or the second main fuel nozzle 5 of the cylinder liner is set on the cylinder liner; the ignition chamber 8 is set on the cylinder head, and the ignition chamber is set on the ignition chamber 8 Reformed gas nozzle 9 and spark plug 10, the ignition chamber 8 is connected to the combustion chamber 3 through a channel; or a cylinder liner reformed gas nozzle 11 is provided on the cylinder liner; the ignition mode of the engine is that the spark plug 10 ignites the ignition chamber 8 The internally reformed gas and the flame jet rich in active radicals are sprayed into the combustion chamber 3...

Embodiment 2

[0046] Embodiment 2: The difference from Embodiment 1 is that the first main fuel nozzle 4 of the cylinder liner is reduced, and the injection is made through the first main fuel nozzle 6 of the cylinder head, the second main fuel nozzle 7 of the cylinder head and the second main fuel nozzle 5 of the cylinder liner The main fuel is mixed with reformed gas to achieve efficient and clean combustion.

Embodiment 3

[0047] Embodiment 3: The difference from Embodiment 1 is that the first main fuel nozzle 6 of the cylinder head is reduced, and the injection is made through the first main fuel nozzle 4 of the cylinder liner, the second main fuel nozzle 5 of the cylinder liner and the second main fuel nozzle 7 of the cylinder head The main fuel is mixed with reformed gas to achieve efficient and clean combustion.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap