A cam slider plunger pump

A technology of cam slider and plunger pump, which is applied in the field of liquid ultra-high pressure, can solve the problems of easy wear failure rate of connecting rod and crosshead, limited increase of pump output pressure, large volume of ultra-high pressure pump, etc., to avoid positioning Difficulty, improved reliability, and good concentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

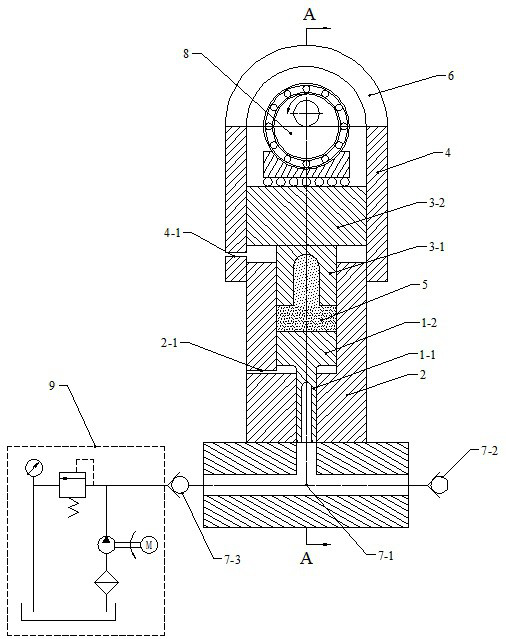

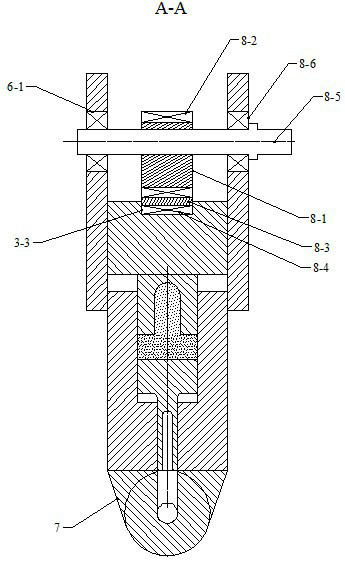

[0019] Such as figure 1 and figure 2 As shown, a cam slider type plunger pump includes a plunger-piston group, a cylinder, a transmission bearing seat 6, a high pressure pump fluid end 7, a cam slider group 8 and a low pressure oil supply system 9; the cylinder The barrel includes a piston cylinder 4 and a plunger cylinder 2, the inner diameter of the piston cylinder 4 is equal to the outer diameter of the plunger cylinder 2, and the side wall of the piston cylinder 4 is provided with a piston cylinder air hole 4-1 , the side wall of the plunger cylinder 2 is provided with a plunger cylinder air hole 2-1. The plunger-piston group is arranged inside the cylinder, including a high-pressure end plunger 1-1, a high-pressure end piston 1-2, a pressure transmission medium 5, a low-pressure end plunger 3-1, and a low-pressure end piston 3 -2, the high-pressure end plunger 1-1 is arranged under the high-pressure end piston 1-2, the low-pressure end plunger 3-1 is arranged under the...

specific Embodiment approach 2

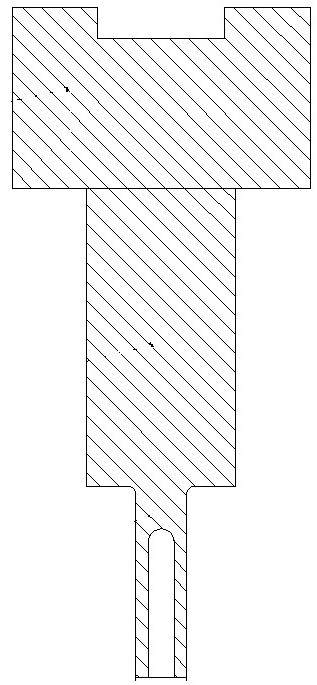

[0022] Such as figure 1 , figure 2 and image 3 As shown, a cam slider type plunger pump includes a stepped shaft, a cylinder, a transmission bearing housing 6, a high-pressure pump fluid end 7, a cam slider group 8 and a low-pressure oil supply system 9; the cylinder includes a piston Cylinder 4 and plunger cylinder 2, the inner diameter of described piston cylinder 4 is equal to the outer diameter of plunger cylinder 2, is provided with piston cylinder air hole 4-1 on the side wall of described piston cylinder 4, described The side wall of the plunger cylinder 2 is provided with a plunger cylinder air hole 2-1. A stepped shaft is arranged inside the cylinder, a slider groove is arranged on the upper part of the stepped shaft, and a cylindrical groove is arranged on the lowermost part of the stepped shaft, and the groove coincides with the central axis of the stepped shaft ; The transmission bearing seat 6 is fixed on the top of the piston cylinder 4, and the cam slider g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com