Seabed volcanic rock sampling device for marine mineral exploration

A sampling device and volcanic rock technology, applied in the direction of sampling devices, etc., can solve the problems of not being able to clear the surrounding environment of the target sampling layer, easily destroying the integrity of the sampling layer, and sampling layers that cannot be sampled, so as to improve integrity and clarity , convenient sampling, prevent winding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

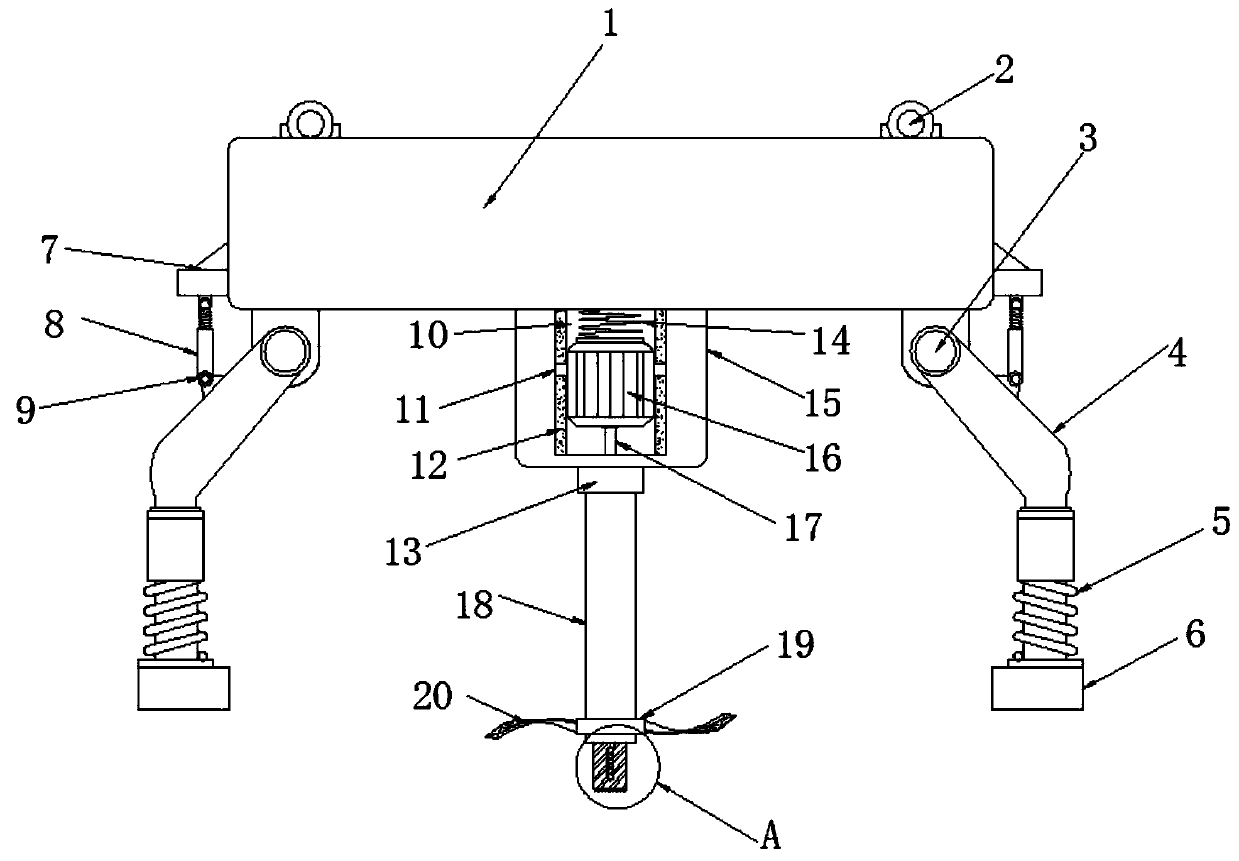

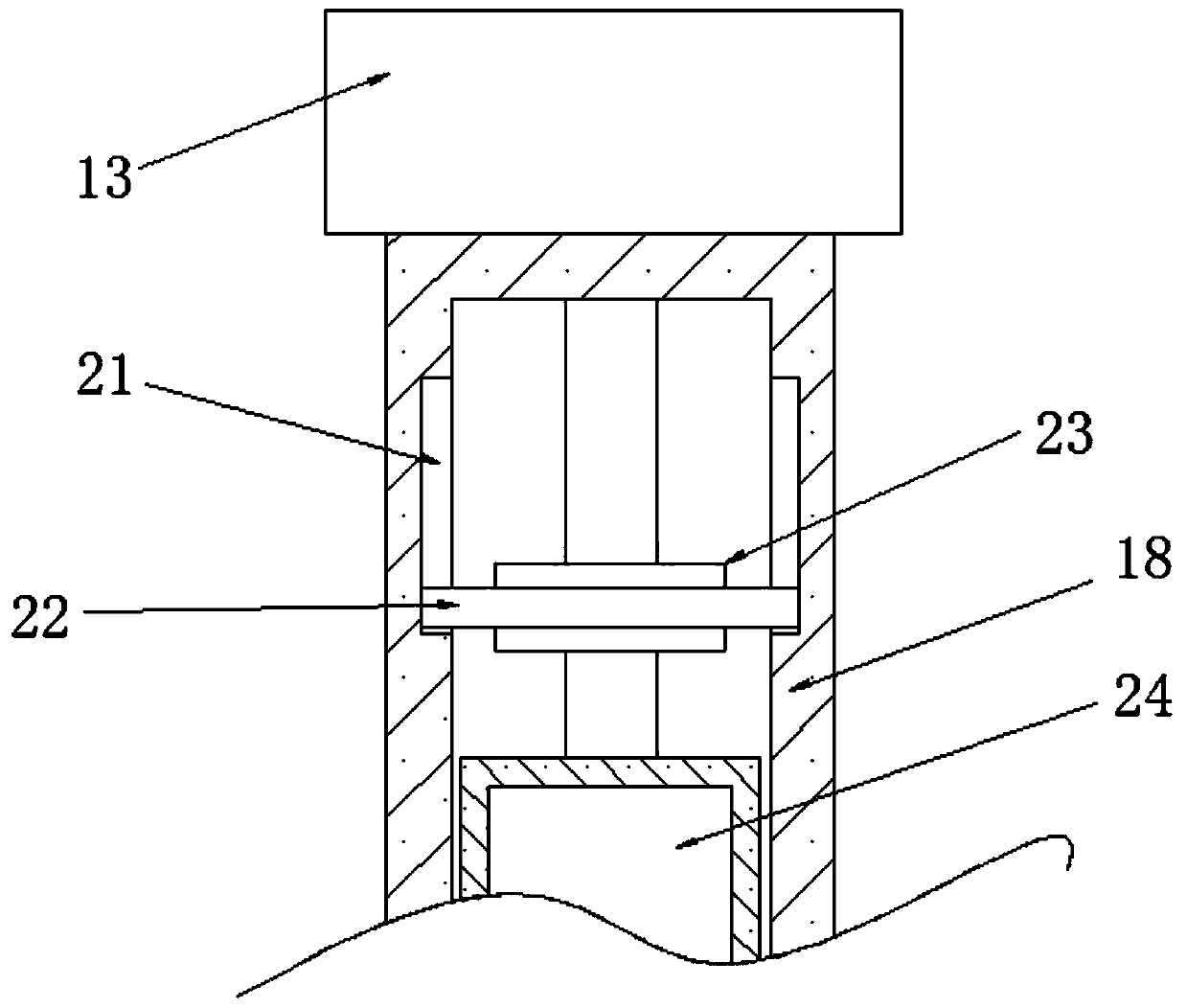

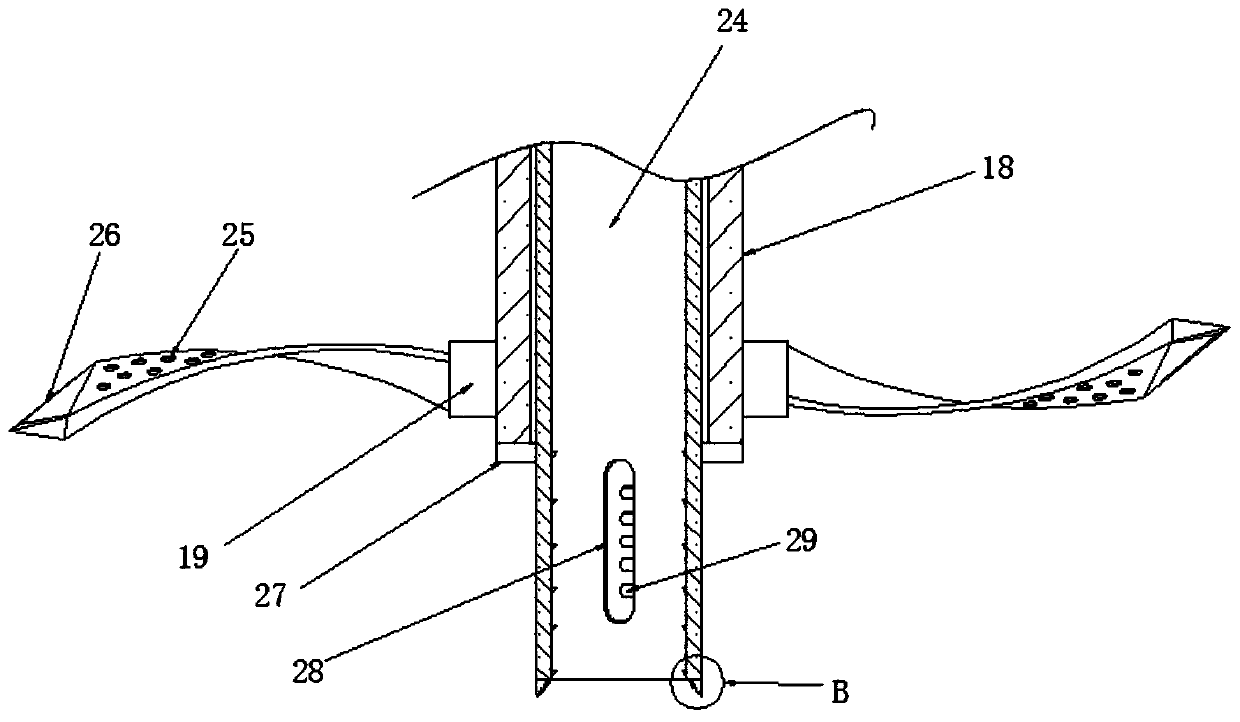

[0029] refer to Figure 1-5 A seabed volcanic rock sampling device for marine mineral exploration, comprising a sampling body 1, a connecting ring 2 with an equidistant annular distribution welded on the top outer wall of the sampling body 1, and a fixed block 7 with an equidistant annular distribution welded on the outer wall of one side of the sampling body 1, for sampling The edge of the outer wall of the bottom of the body 1 is welded with connecting ears 3 equidistant and circularly distributed, and a circular through hole is opened on one side of the outer wall of the connecting ear 3, and a bending arm 4 is inserted into the circular through hole, and the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com