Thermodynamic calculation method for precipitation of quaternary second-phase precipitates in ferrite steel

A calculation method, ferritic steel technology, applied in the field of physical chemistry of metal materials, to achieve the effect of high stamping forming ability, strong ductility, high yield strength and tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The invention discloses a thermodynamic calculation method for the precipitation of quaternary second phase precipitates in ferritic steel. Microalloying technology is adopted in iron and steel materials, and microalloying elements such as Nb, V, and Ti are added, which can play a role in microalloying. crystallization and precipitation strengthening.

[0030] In addition, the combination of microalloying elements with carbon and nitrogen can also fix carbon and nitrogen, which can weaken (or even eliminate) the harm of carbon and nitrogen solid solution strengthening to plasticity and toughness, and thermodynamic calculations have theoretical implications for the production of microalloys. Guiding significance.

[0031] For achieving the above object, technical scheme of the present invention is:

[0032] The thermodynamic precipitation behavior of C-N-Nb-V system hot-rolled TRIP steel in the austenite zone was calculated, and then the composite precipitated (M′ X M″...

Embodiment 2

[0045] Precipitation thermodynamic model establishment:

[0046] The present invention is based on (M') established by J.G.Speer X M″ 1-X )(C y N 1-y ) model for calculation, and for the compound calculation (M′ X M″ 1-X )(C y N 1-y ) can be linearly decomposed into m 1 (MˊC),m 2 (MˊN),m 3 (MˊˊC),m 4 (MˊˊN), where

[0047] m 1 +m 2 =x; (1)

[0048] m 3 +m 4 =1-x; (2)

[0049] m 1 +m 3 =y; (3)

[0050] m 2 +m 4 =1-y; (4)

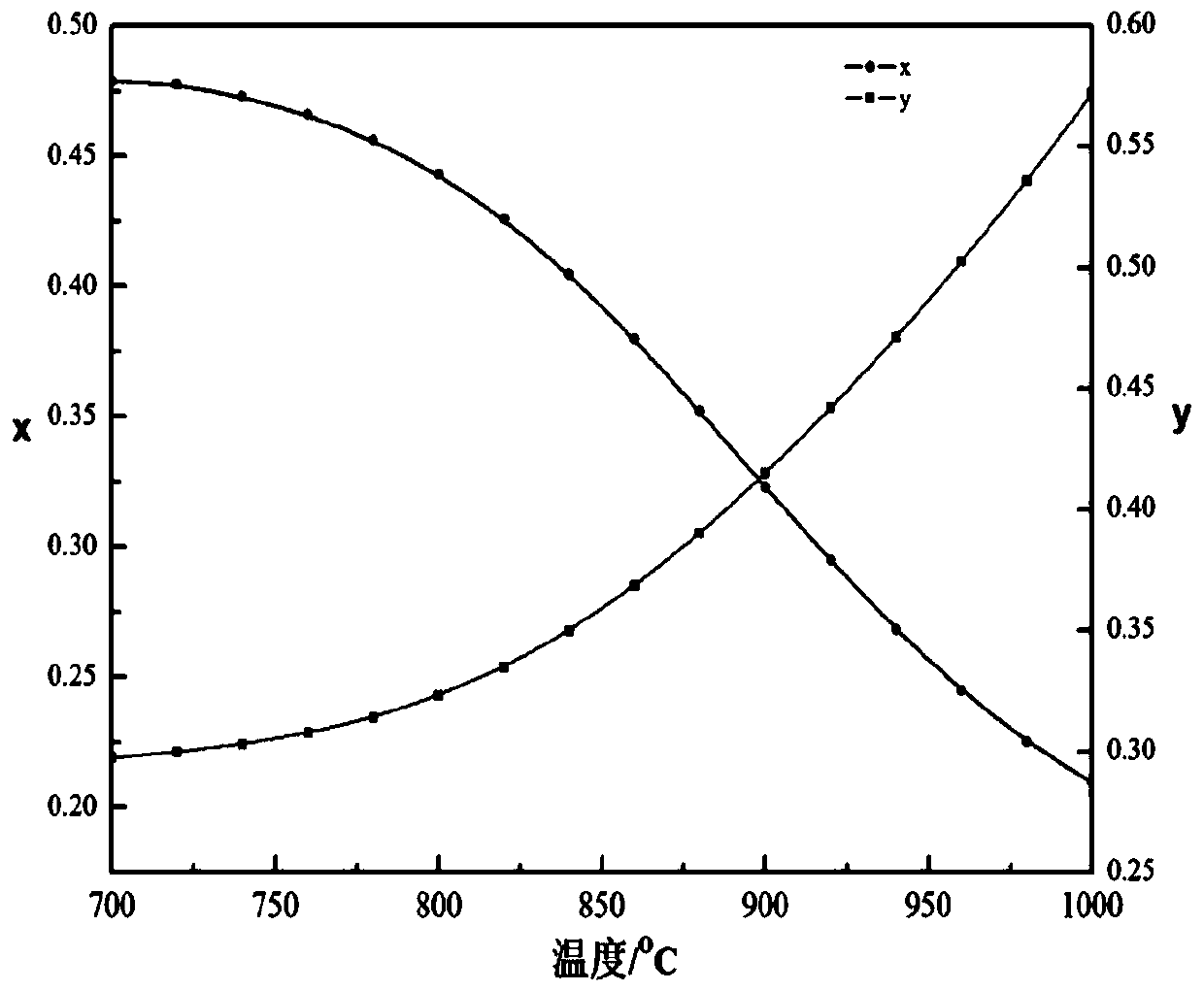

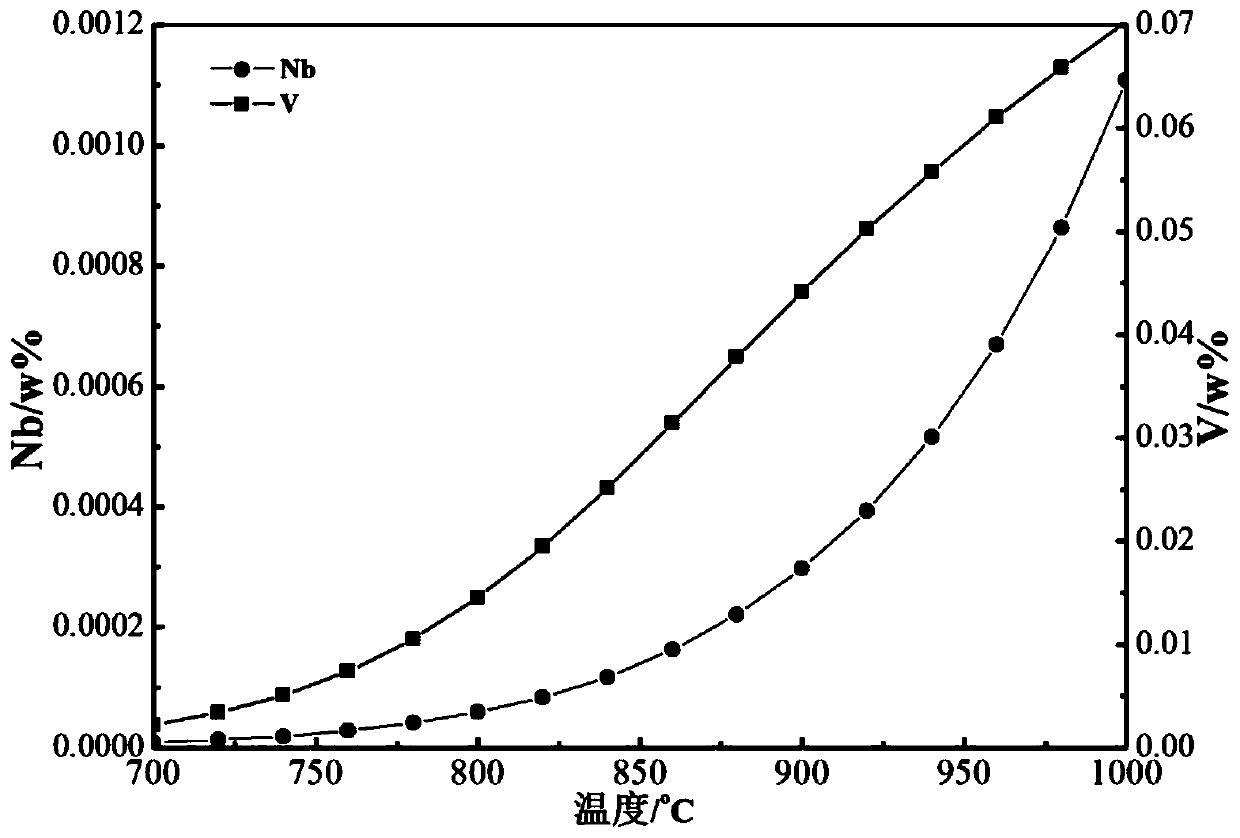

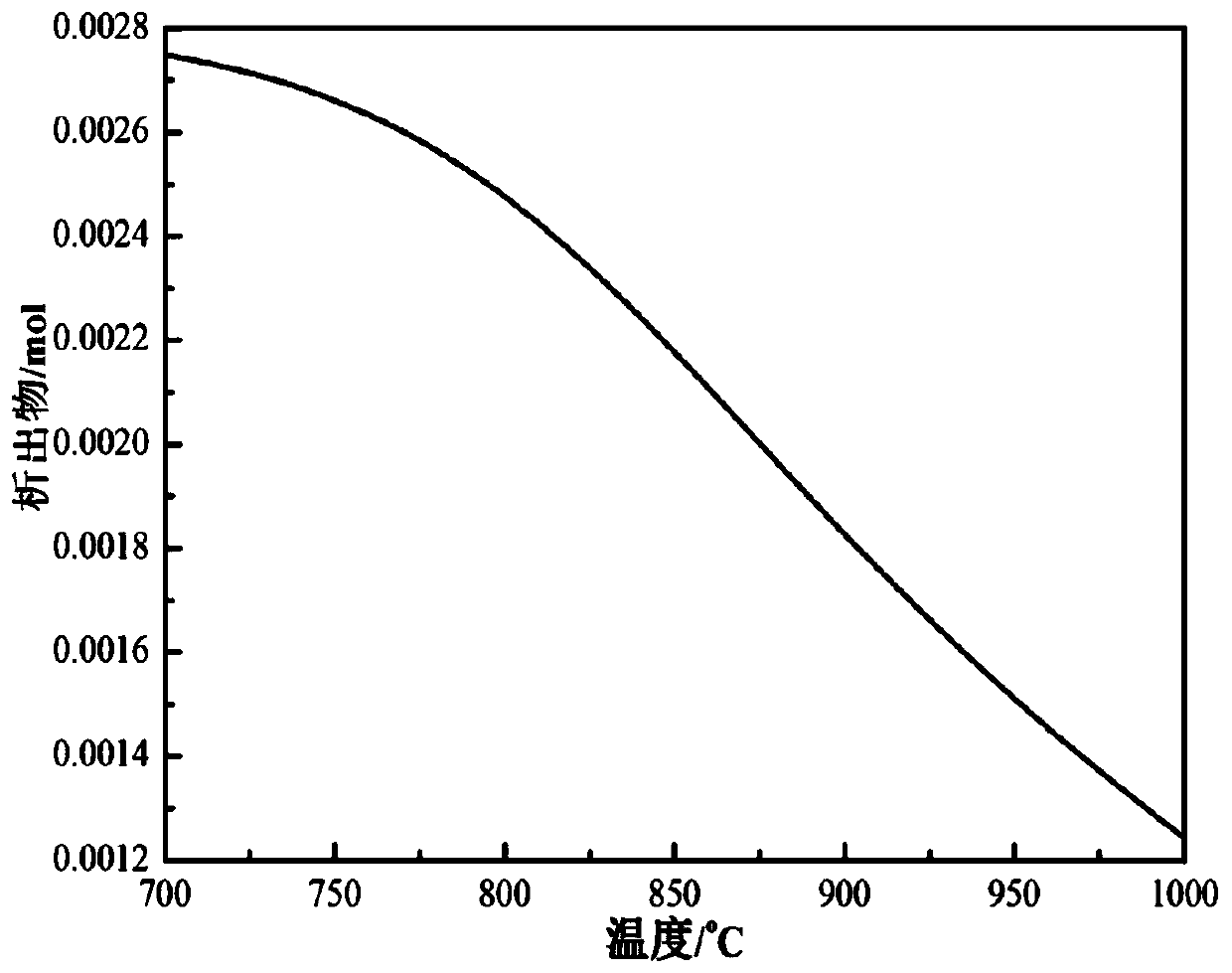

[0051] Take the compound addition of Nb and V as an example, that is, the compound precipitates are (NbxV1-x)(CyN1-y), for different values of x and y, the solid state of (Nb,V)(C,N) in austenite The solubility product formula will also change. Using linear interpolation method, firstly, the solid solubility product formula of (Nb,V)(C,N) at different x and y values is obtained, and its general form can be expressed as the formula:

[0052] lg{[Nb] x [V] (1-x) [C] y [N] (1-y)}=2.96*m 1 +3.7*m 2 +6.72*m 3 +3.63*m 4 +m 1 *lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com