Copper sheet bending device and bending method for fuse boxes

A fuse box and bending device technology, applied in fuse manufacturing, other manufacturing equipment/tools, metal processing, etc., can solve problems such as the bending of copper sheets in the fuse box, improve bending quality, improve bending efficiency, and improve The effect of press-fit assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

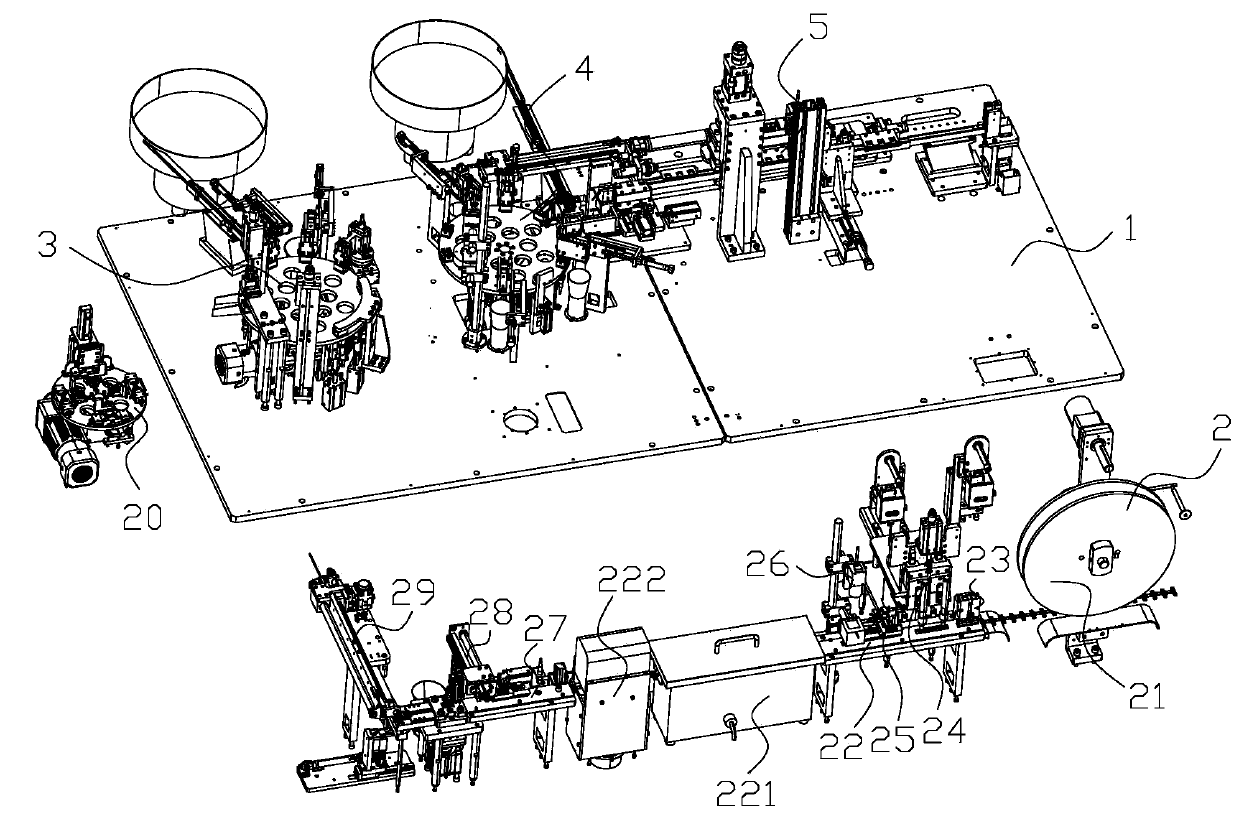

[0030] Such as figure 1 As shown, a fuse box production equipment includes a frame 1, a copper sheet feeding processing device 2, a copper sheet bending device, a shell feeding assembly device 3, a cover plate feeding assembly device 4 and a fixed detection device 5 The copper sheet feeding processing device 2, the copper sheet bending device, the shell feeding assembly device 3, the cover plate feeding assembly device 4 and the fixed detection device 5 are arranged on the frame 1, and the output of the copper sheet feeding processing device 2 The feed end is connected to the feed end of the shell feed assembly device 3; the copper sheet feed processing device 2 is used to feed the copper sheet and perform positioning and punching; the copper sheet bending device is used to bend the copper sheet; The shell feed assembly device 3 is used to feed the shell and assemble it with the copper sheet; the feed end of the cover plate feed assembly device 4 is connected with the discharg...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap