Outer rotor brushless motor

A brushless motor and outer rotor technology, applied in electrical components, electromechanical devices, and connection with control/drive circuits, etc., can solve the problems of increased assembly difficulty, small thermal contact area, damaged insulation layer, etc., to improve reliability, High assembly precision and avoid open circuit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below through specific examples.

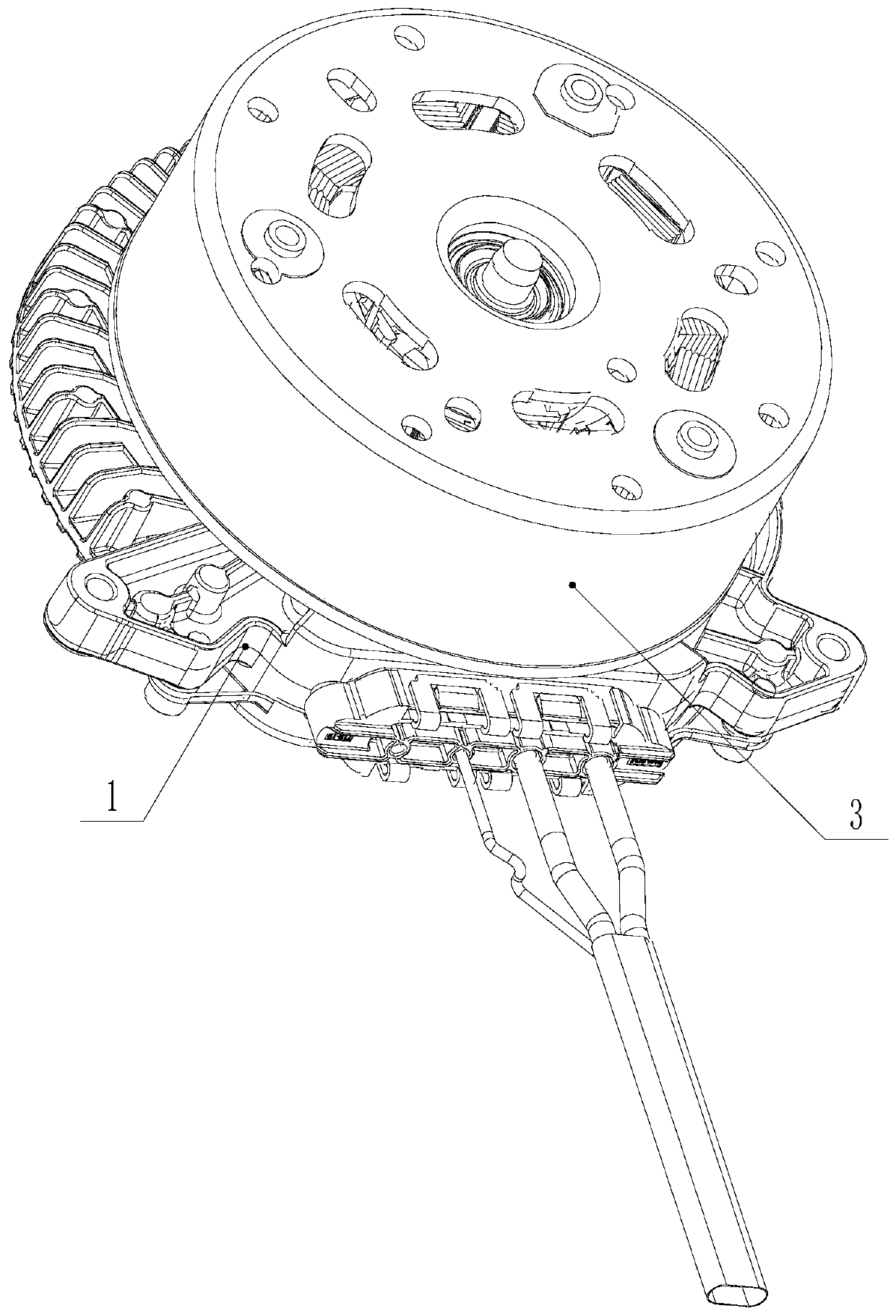

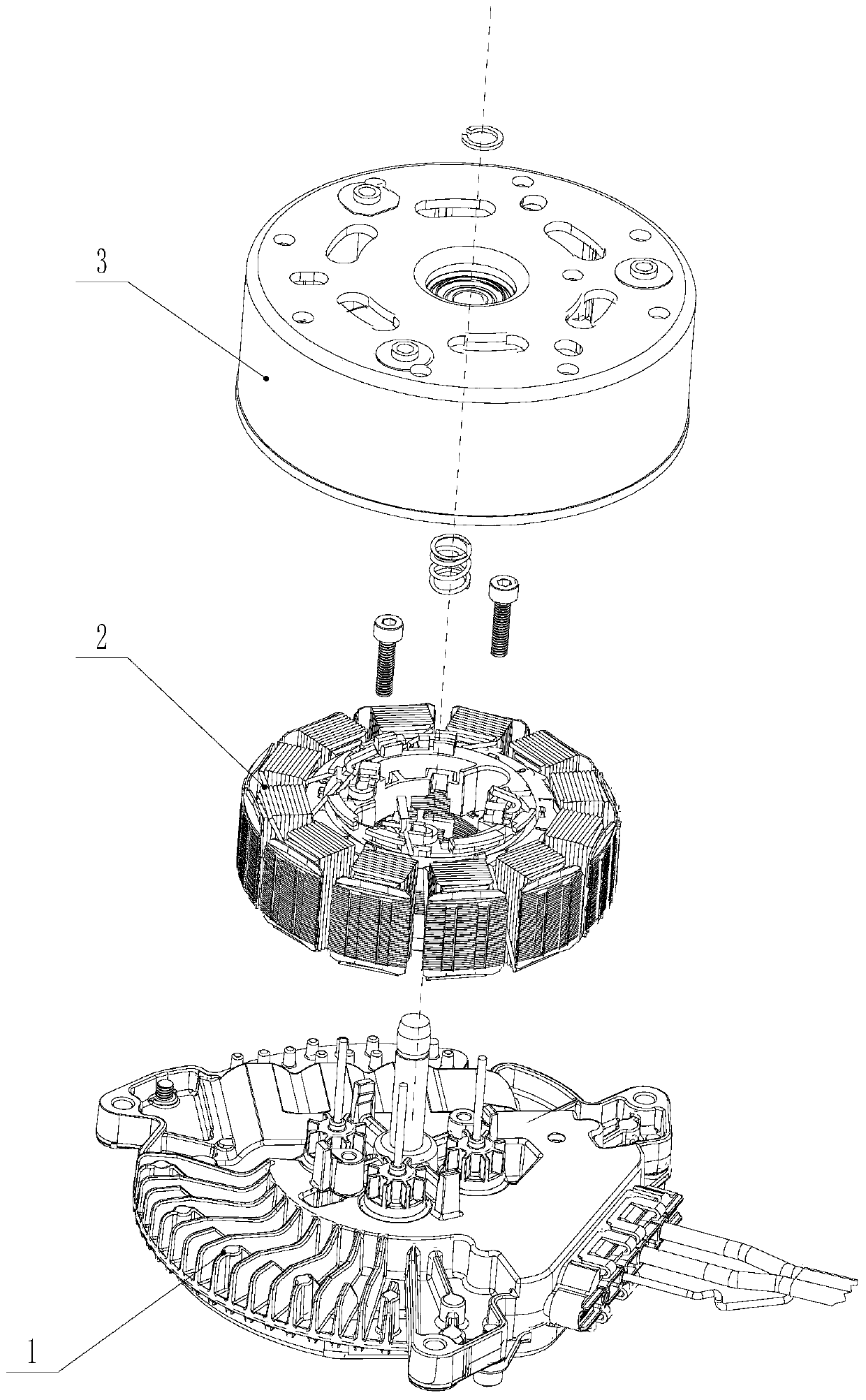

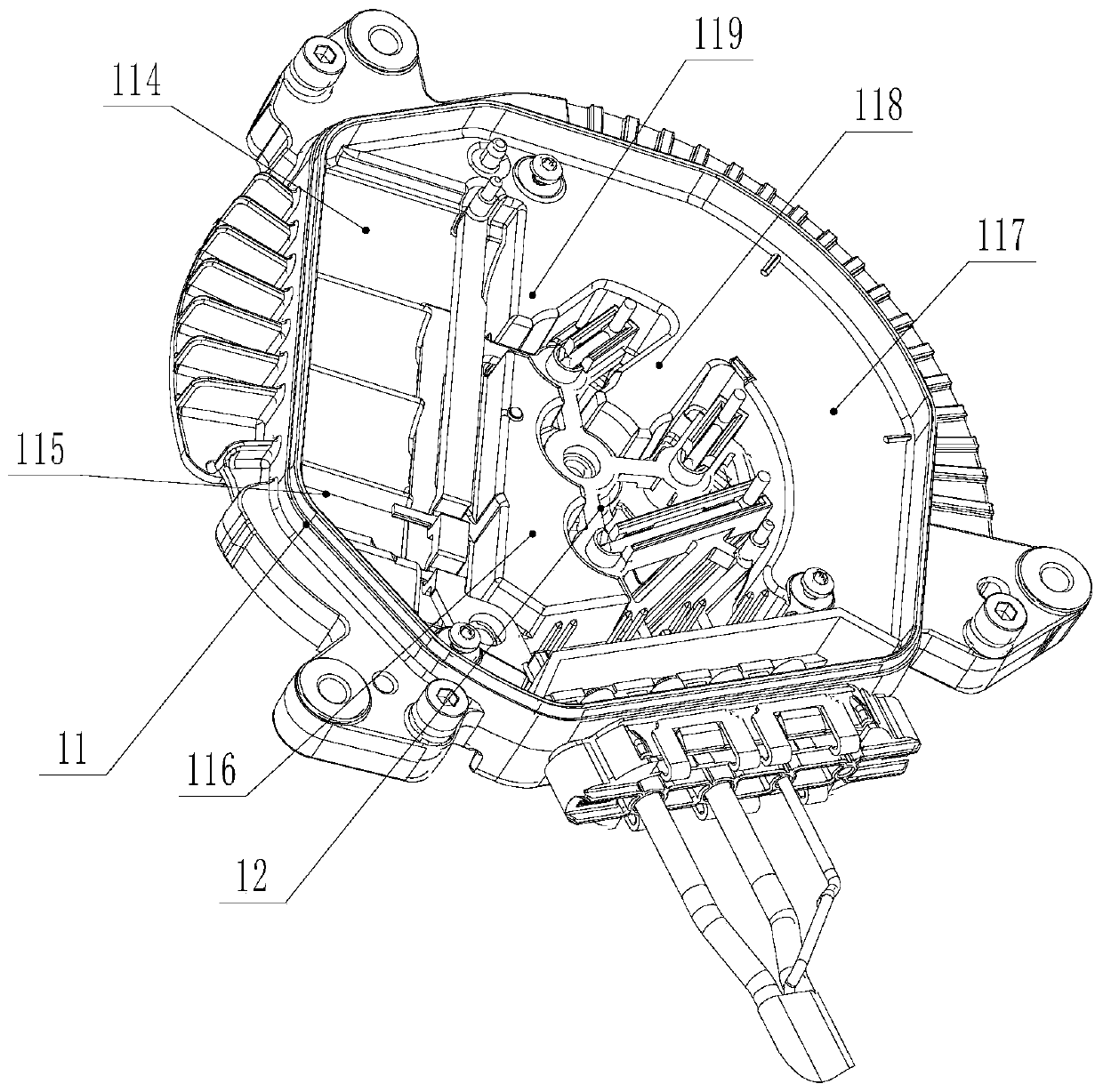

[0028] Such as Figure 1 to Figure 10 As shown, a brushless motor with an outer rotor includes a controller set, and the controller set includes a housing composed of a heat sink 11 and a rear end cover 13, and a conductive bracket 12 and a PCBA are arranged inside the housing plate, the front of the heat sink 11 is provided with a central shaft, the front of the heat sink 11 is equipped with an armature assembly 2, the central shaft is rotated and installed with an outer rotor assembly 3, and the heat sink 11 is provided with a capacitor installation area 114, inductance installation area 115, conductive support 12 installation area 1110, wire harness connector area and heat conduction platform, described conductive support 12 is placed in the conductive support 12 installation area 1110, and capacitor is installed in the capacitance installation area 114, in the inductance ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com