Harmless treatment method for solid wastes of offshore oil drilling platform

A technology for the harmless treatment of solid waste, applied in the field of offshore drilling platforms, can solve the problems of small drilling platform space, poor integrity of finished products, and small storage space for ton bags, so as to reduce the difficulty of laying and unloading, and reduce the follow-up Processing time, the effect of improving the degree of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This example provides a specific implementation of a method for harmless treatment of solid waste from an offshore oil drilling platform.

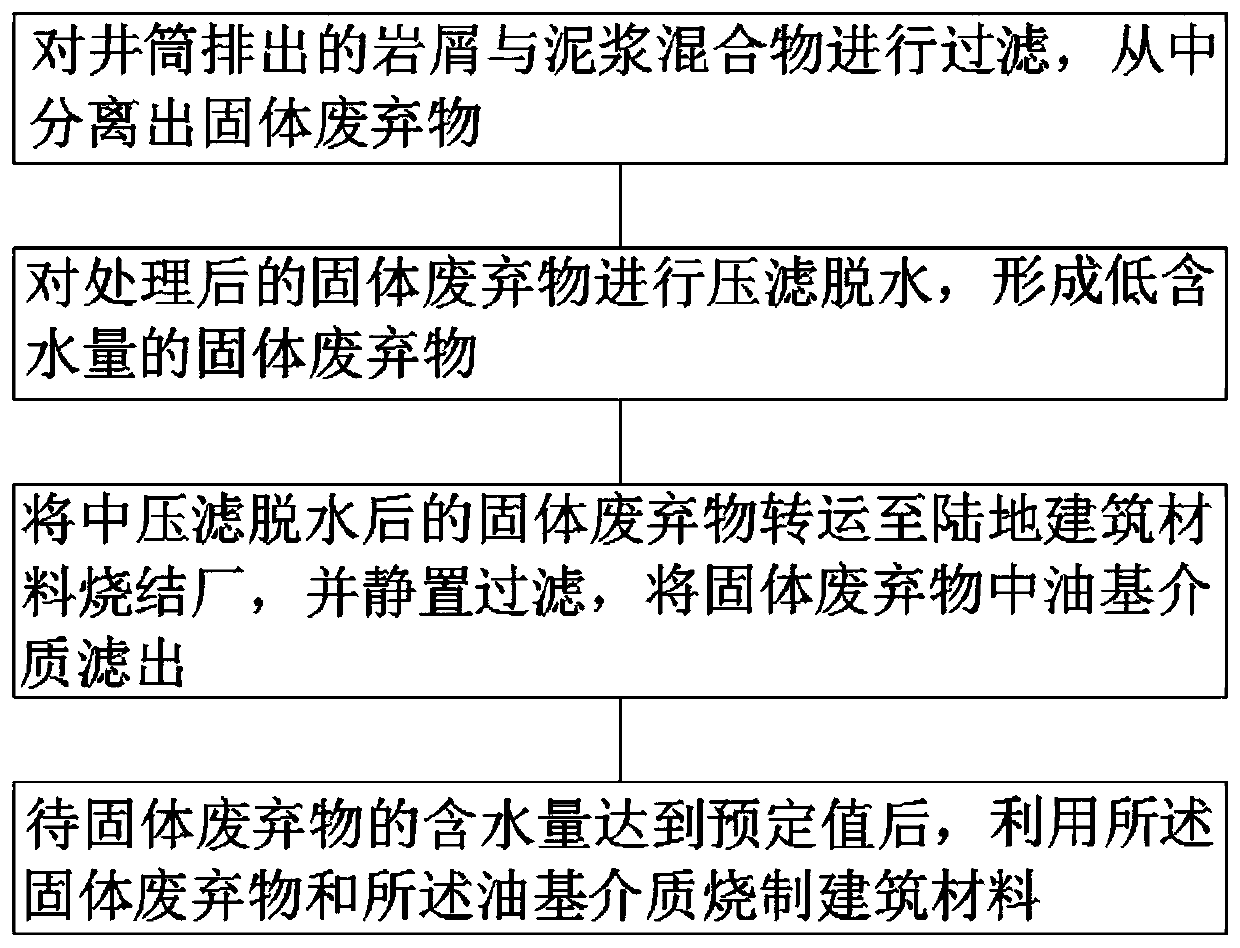

[0042] refer to figure 1 As shown, a method for harmless treatment of solid waste on an offshore oil drilling platform comprises the following steps:

[0043] (1) Filter the cuttings and mud mixture discharged from the shaft, and separate solid waste therefrom. The water content in the cuttings and mud mixture discharged from the shaft is 85-95%;

[0044] (2) performing pressure filtration and dehydration on the solid waste treated in step (1) to form solid waste with low water content. After pressure filtration, the water content in the solid waste is 60-70%;

[0045](3) Transfer the solid waste after pressure filtration and dehydration in step (2) to the land building material sintering plant, and let it stand for filtration, filter out the oil-based medium in the solid waste, and transfer the solid waste through the transfer box...

Embodiment 2

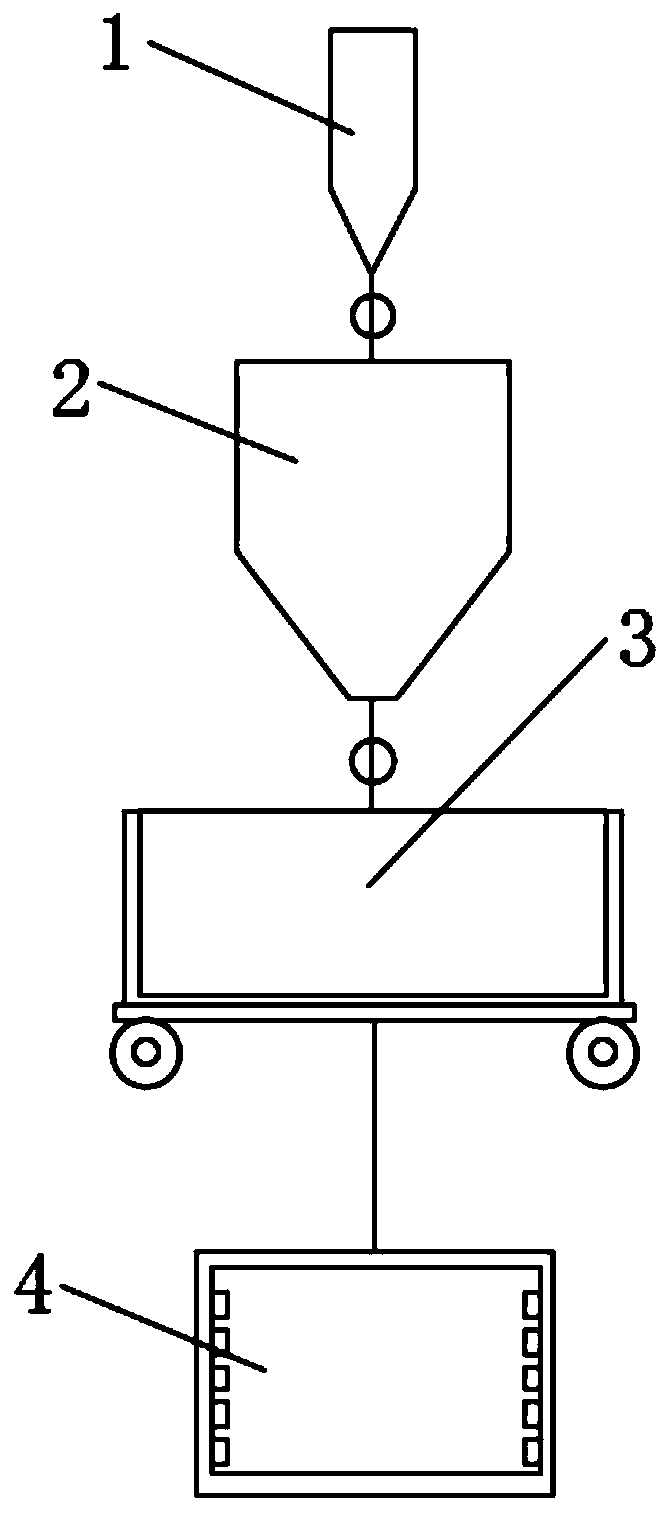

[0052] refer to figure 2 As shown, this embodiment provides a device for harmless treatment of solid waste on an offshore oil drilling platform used in the method described in Embodiment 1. The device for the harmless treatment of solid waste on an offshore oil drilling platform includes a raw material bin 1 for storing solid waste, and a solid-liquid separation device 2 for solid-liquid separation of the solid waste stored in the raw material bin 1. A transfer device 3 for transporting the solid waste treated by the solid-liquid separation device 2, and a firing device 4 for burning building materials using the solid waste. The solid waste harmless treatment device of the offshore oil drilling platform can realize the integrated treatment of solid waste separation, dehydration, transfer and sintering.

[0053] The solid waste may come directly from drilling, or from the solid waste stored in the raw material bin 1 .

Embodiment 3

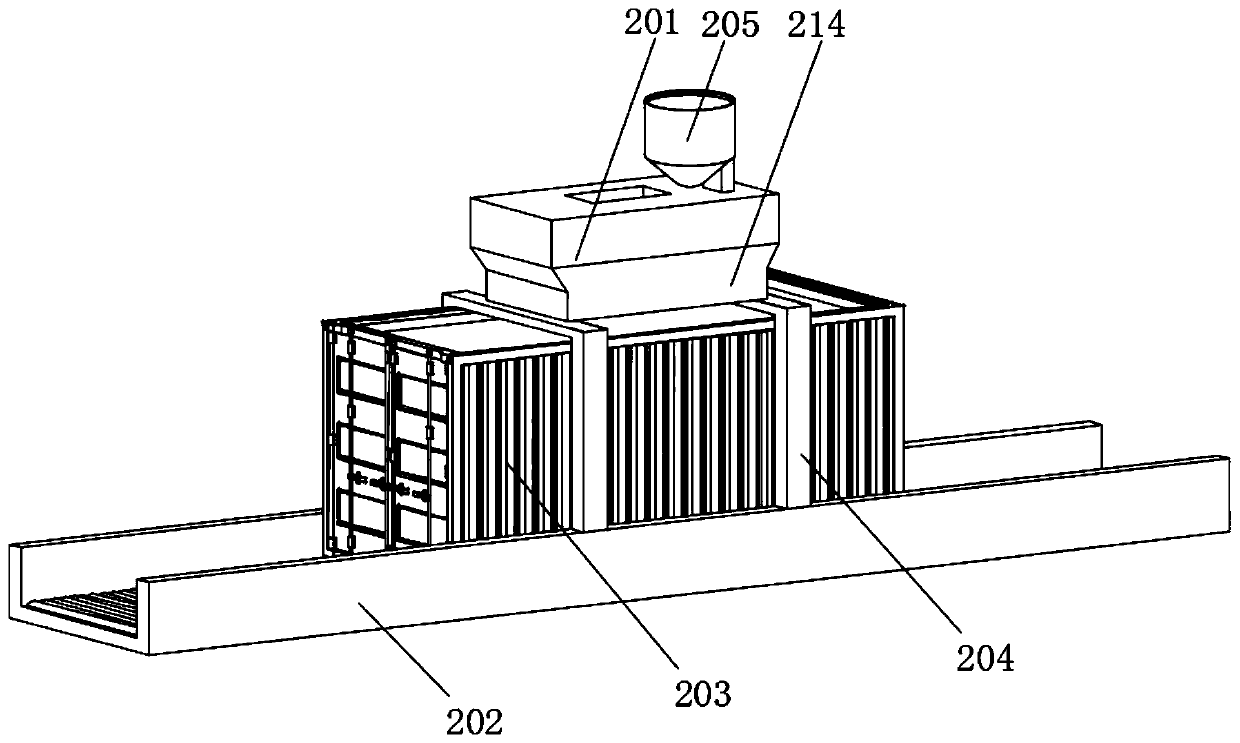

[0055] refer to Figure 3-Figure 6 As shown, this embodiment provides a solid-liquid separation device 2 for solid waste separation used in the device described in Embodiment 2. The solid-liquid separation device 2 includes a separation box 201 for solid-liquid separation of cuttings and mud mixture, a transport frame 202 for supporting the separation box 201, and a transfer box 203 for storing cuttings and mud separated by the separation box 201 , the inside of the separation box 201 is equipped with a centrifugal separation mechanism, the inside of the separation box 201 is provided with an air supply mechanism near the top of the centrifugal separation mechanism, and the bottom of the separation box 201 is provided with a filter press mechanism, wherein:

[0056] The centrifugal separation mechanism includes a separation drum 209 for rotating and filtering the mixture of cuttings and mud and a driving motor 210 for driving the rotation of the separation drum 209. The separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com