Homing type topological optimization method for mortise and tenon joint structure design

A connection structure and topology optimization technology, applied in design optimization/simulation, special data processing applications, geometric CAD, etc., can solve the problem that the boundary conditions of mortise and tenon structures cannot be applied drastically, and cannot give inspiring new structures. The direction and range of the form and shape change are limited, so as to improve the contact conditions and stress concentration, improve the global optimization ability, and improve the contact conditions and stress concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The following is attached Figure 1-11 The technical solutions involved in the present invention are described in detail.

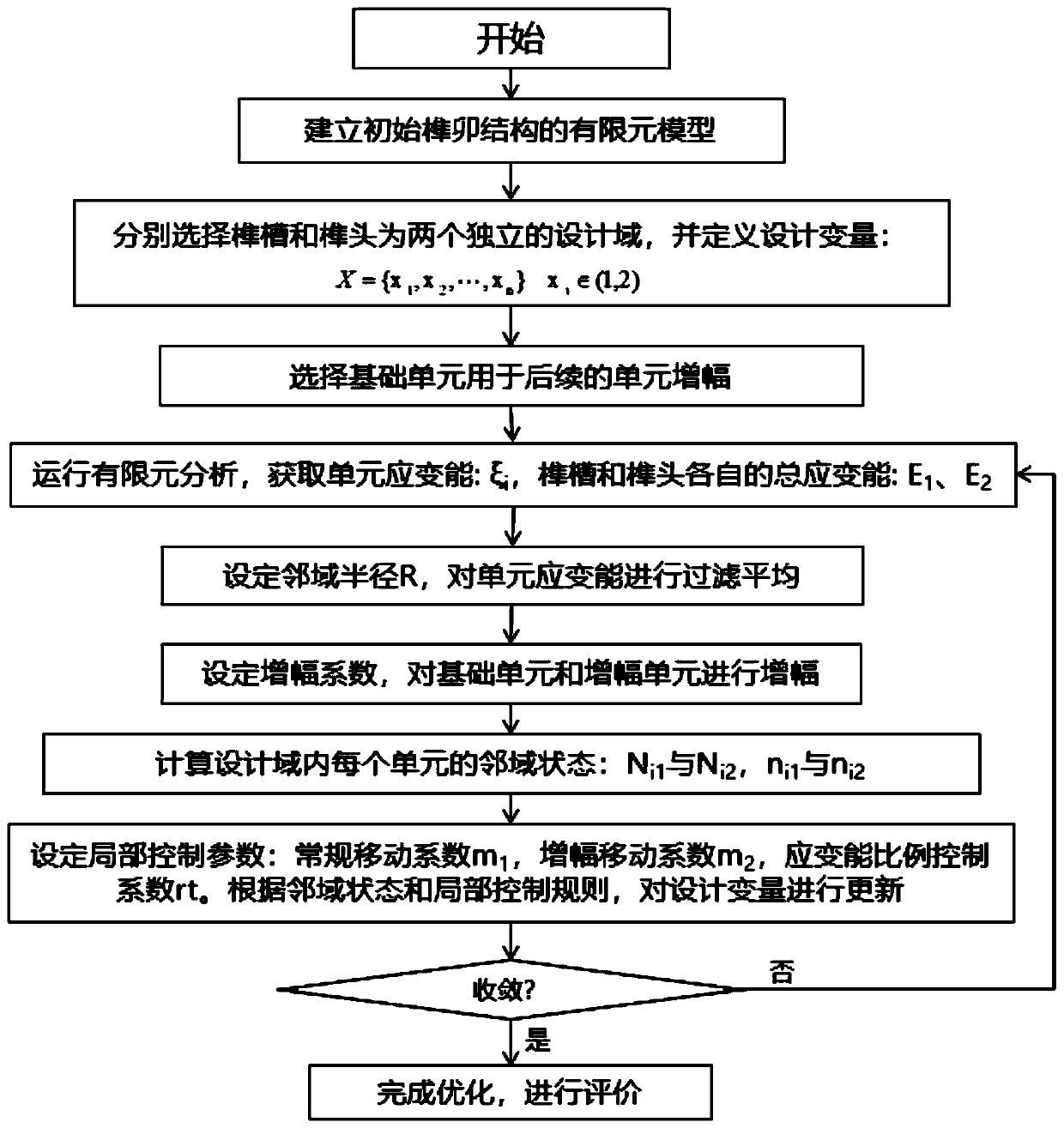

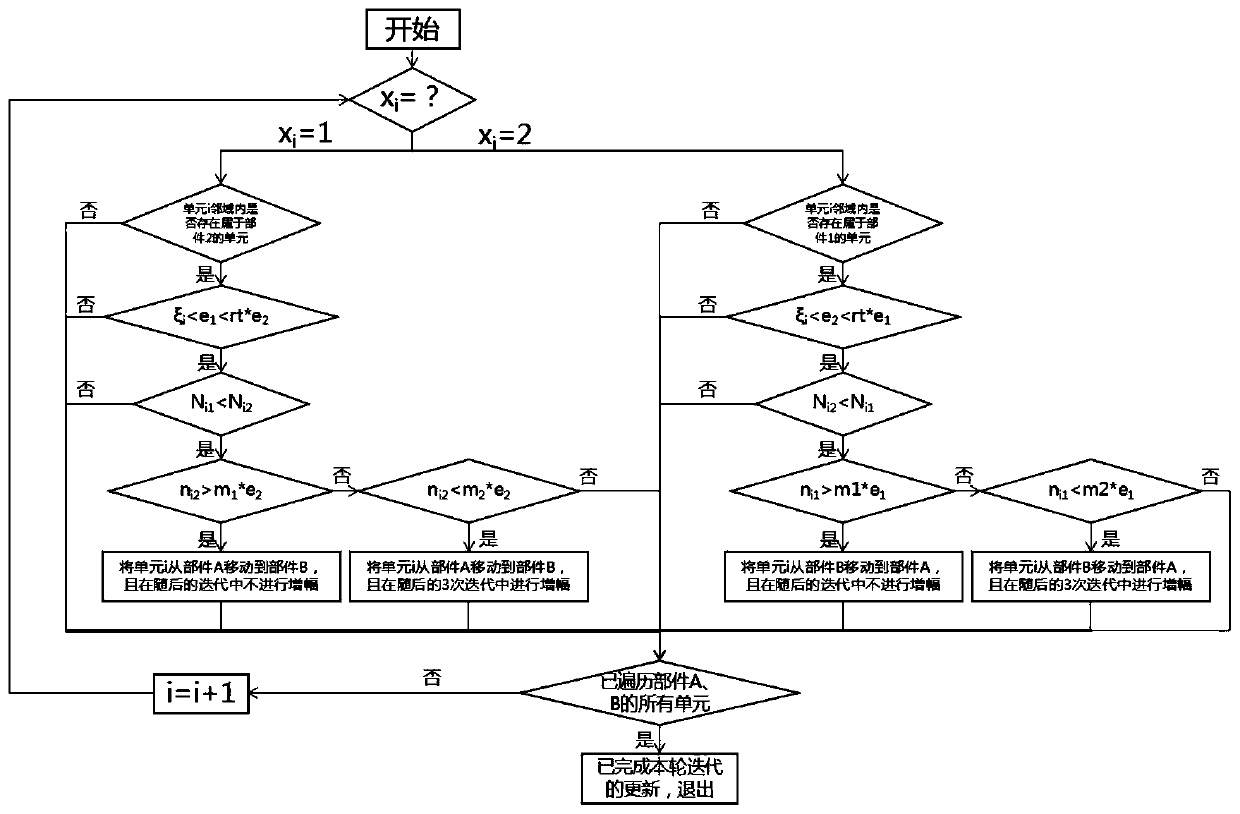

[0058] Such as figure 1 As shown, this embodiment provides a method for recursive topology optimization for the design of mortise and tenon joint structures, which specifically includes the following steps:

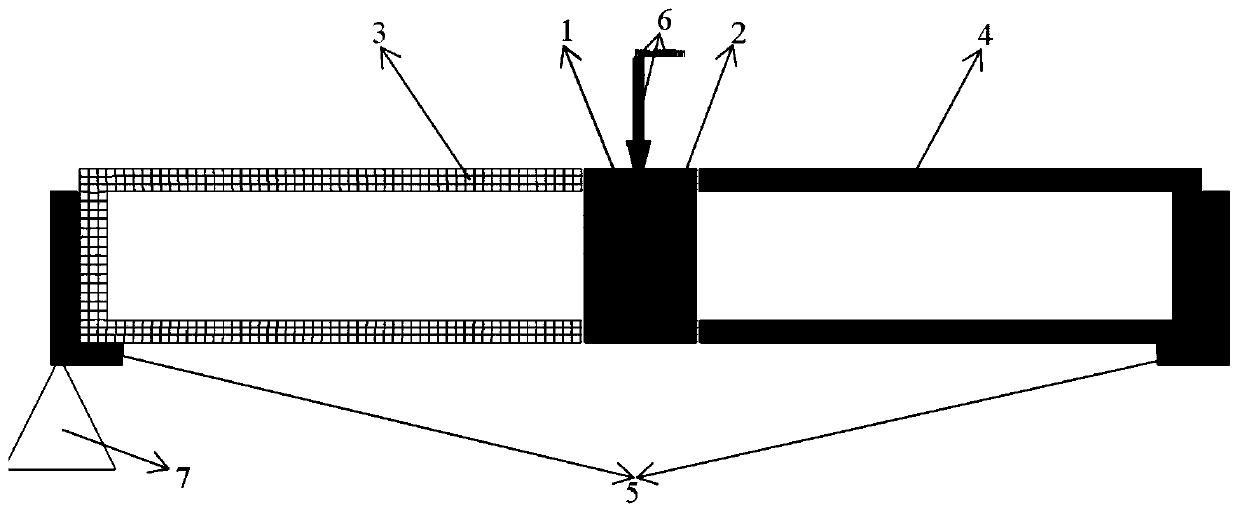

[0059] Step 1. Establish the finite element model of the structure to be optimized. The model includes: tenon groove 1, tenon head 2, left bearing structure 3, right bearing structure 4, support 5, downforce load 6 and constraint 7 on the support, The units of tenon and tenon 1 and tenon 2 are the design domain of the optimization problem. The selection of the design domain and the definition of the design variables will be detailed in step 2.

[0060] The established finite element model needs to ensure that the tenon 2 and the tenon groove 1 are completely fitted at the contact surface, and the grid nodes of the tenon 2 and the tenon groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com