Machining method of extrusion die

A processing method and extrusion die technology, applied in metal extrusion forming tools, metal extrusion, metal processing equipment, etc., can solve the problems of long processing cycle and slow processing efficiency of extrusion dies, and achieve processing accuracy guarantee, The effect of short production cycle and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention will be described in further non-limiting detail below in combination with preferred embodiments and accompanying drawings.

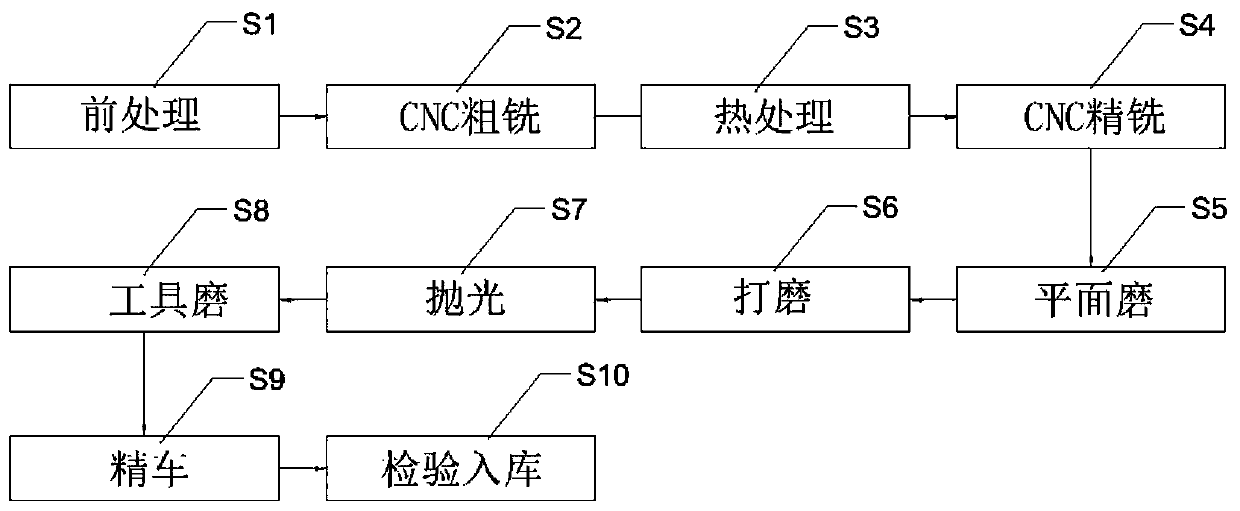

[0024] The invention provides a method for processing an extrusion die, comprising the steps of:

[0025] S1. Pre-processing: Pre-processing includes blanking, rough turning and drilling in sequence, so as to process the outer circle, assembly surface, diversion hole and seam of the upper and lower dies. Rough turning mainly refers to turning out the outer circle, assembly surface and seam of the mold on the CNC lathe or ordinary lathe according to the requirements of the design drawings. Drilling is the use of machine tools to process the process holes and threaded holes of the upper and lower dies.

[0026] S2. CNC rough milling: including rough milling of the upper mold and rough milling of the lower mold. The rough milling of the upper mold is mainly based on the requirements of the drawing on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com