Automobile pillar B cross beam fixture

A crossbeam and B-pillar technology, which is applied to vehicle parts, manufacturing tools, auxiliary devices, etc., can solve the problems of lack of positioning of small parts, reduce processing accuracy, and occupy too much space, so as to improve positioning accuracy and processing accuracy, and improve Clamping stability, avoiding the effect of manual positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

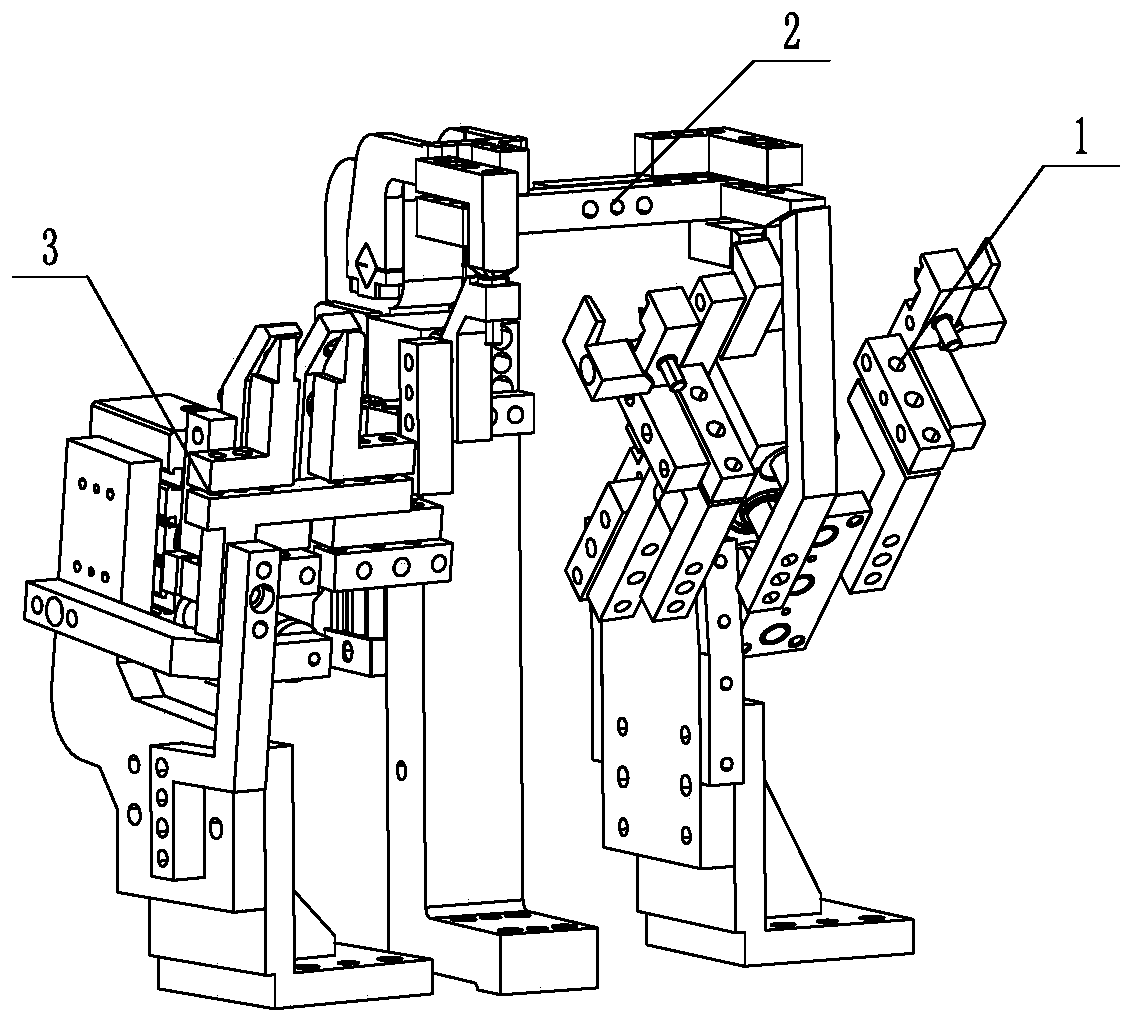

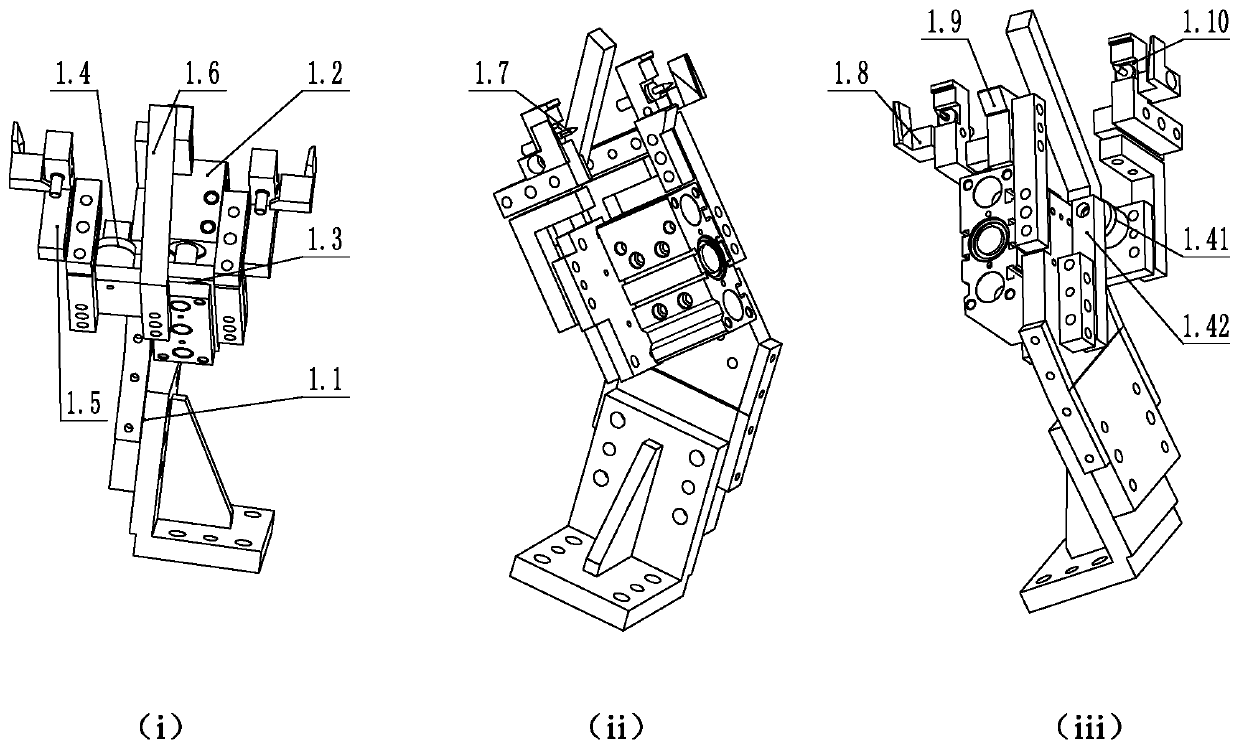

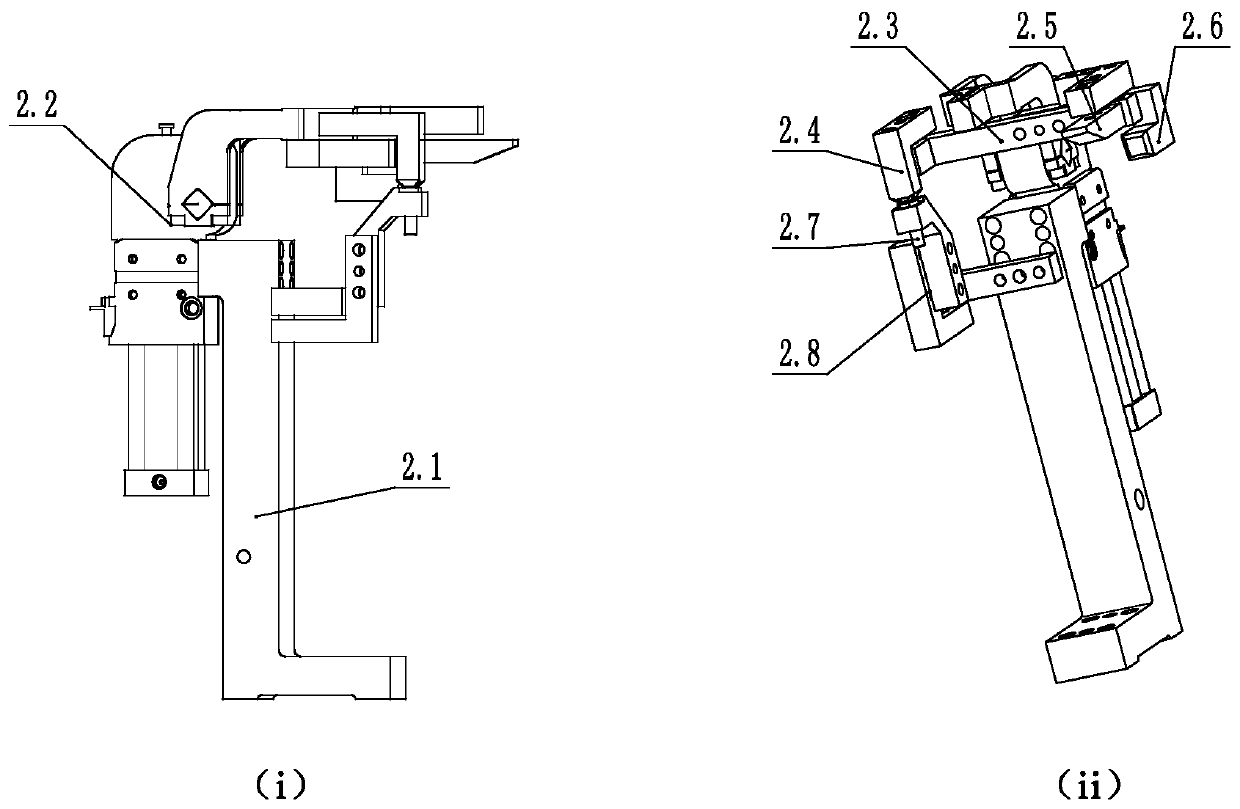

[0034] Such as Figure 1-4As shown, an automobile B-pillar crossbeam clamp includes a protrusion positioning unit 1, a clamping unit 2 and a positioning block positioning unit 3 arranged in sequence on the same substrate; the protrusion positioning unit 1 includes a first main installation Frame 1.1, the first main mounting frame 1.1 is provided with a first driving device 1.2, the first driving device 1.2 is a three-axis cylinder, the driving rod of the first driving device 1.2 expands and contracts obliquely downward, and the driving rod is fixedly connected to the first The moving plate 1.3 is provided with a contraction limiting device 1.4 within the contraction stroke of the first moving plate 1.3, and the contraction limiting device 1.4 is connected with the first main installation frame 1.1; the left and right ends of the first moving plate 1.3 are respectively provided with a set of protrusions Fixing devices, their structures are consistent and mirror-image symmetrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com