Method and system for controlling addition of polyester waste washing liquid

A washing liquid and polyester technology, applied in the direction of liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of infeasibility, complicated testing process, etc., and achieve stable active ingredient content and increase The effect of quality and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

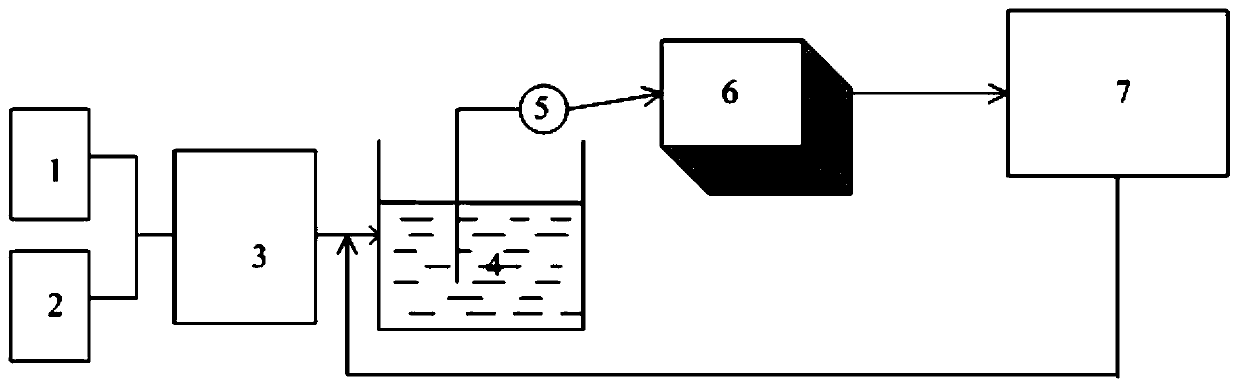

Image

Examples

Embodiment 1

[0062] Unpack the purchased polyester bottle bricks and sort the materials to obtain waste polyester bottles;

[0063] Mix 8000 kg of water, 80 kg of cleaning agent, and 240 kg of sodium hydroxide to obtain a cleaning solution, and place the cleaning solution in a cleaning container (containing water);

[0064] According to the oil stains, label paper, and glue residue characteristics of the above-mentioned waste polyester bottles, the concentration of hydroxide ions in the washing liquid is set to 2.6mol / L;

[0065] Place waste polyester bottles continuously in the above-mentioned washing solution for cleaning; during the cleaning process, take 1ml of washing solution sample from the cleaning container after 2 hours, add phenolphthalein solution at the same time, and titrate with 0.1mol / L hydrochloric acid solution with 10-15ml of distilled water , after detection, the concentration of hydroxide ions in the washing liquid is 1.9mol / L;

[0066] The detected hydroxide ion conc...

Embodiment 2

[0073] The same as the method of controlling the addition of the cleaning liquid in Example 1, the difference is that the concentration of hydroxide ions in the cleaning liquid is set to be 2.6mol / L; the concentration of hydroxide ions in the cleaning liquid obtained after detection is 2.2 mol / L; After calculation, it is necessary to add 33L of the above-mentioned cleaning solution;

[0074] Detect the final cleaned bottle flakes: L (lightness) is 70.5, a (red-green) is -1.3b (blue-yellow) is 3.6. The pvc content is less than 70ppm, and the label sheet content is less than 100ppm.

Embodiment 3

[0076] The same as the method of controlling the addition of the cleaning liquid in Example 1, the difference is that the concentration of hydroxide ions in the cleaning liquid is set to be 3.2mol / L; after detection, the concentration of hydroxide ions in the cleaning liquid is 2.4 mol / L; After calculation, it is necessary to add 39L of the above-mentioned cleaning solution;

[0077] Detect the final cleaned bottle flakes: the L value (lightness) is 71.3, the a value (red-green) is -1.5, and the b value (blue-yellow) is 6.3. The pvc content is less than 80ppm, and the label film content is less than 90ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com