Martensite aging anti-microbial stainless steel and preparation method thereof

An antibacterial stainless steel and martensite technology, applied in the field of materials, can solve the problems of poor material quality, no antibacterial performance, and unstable raw material quality, and achieve excellent strength and toughness matching, hardness and strength improvement, and excellent corrosion resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

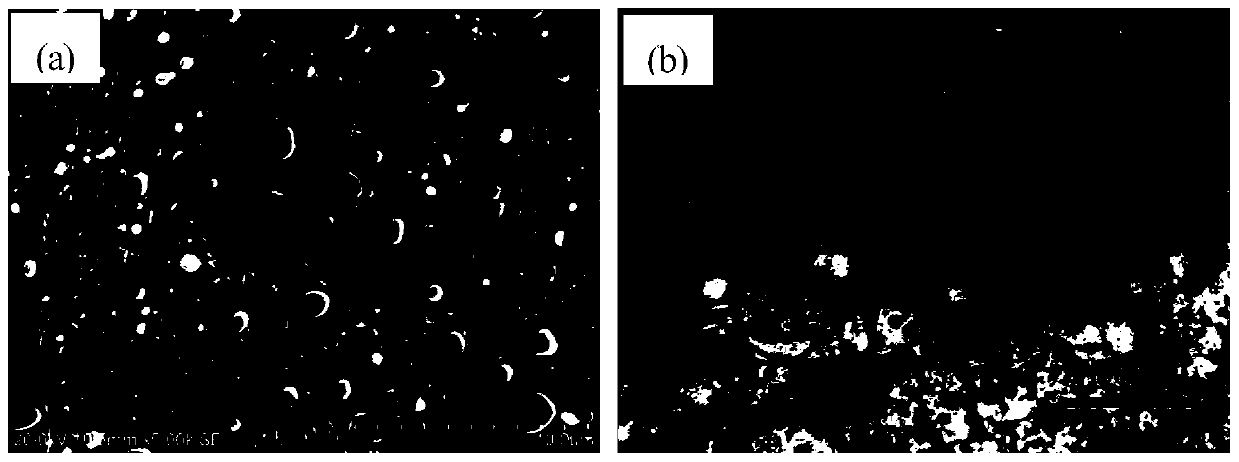

[0048] In the present embodiment, the chemical composition of maraging antibacterial stainless steel is: C: 0.39wt.%, Cr: 13.94wt.%, Cu: 2.52%, Mo: 0.54wt.%, V: 0.12wt.%, Mn : 0.49wt.%, Si: 0.45wt.%, O: 20ppm, N: 250ppm, S: 30ppm, P: 80ppm, and the balance is iron.

[0049] In this example, the heat treatment process after cold rolling: first, quenching after holding at 1050°C for 30 minutes, then holding at 160°C for 150 minutes, then air cooling to room temperature, and finally aging at 500°C for 30 minutes, then air cooling to room temperature.

Embodiment 2

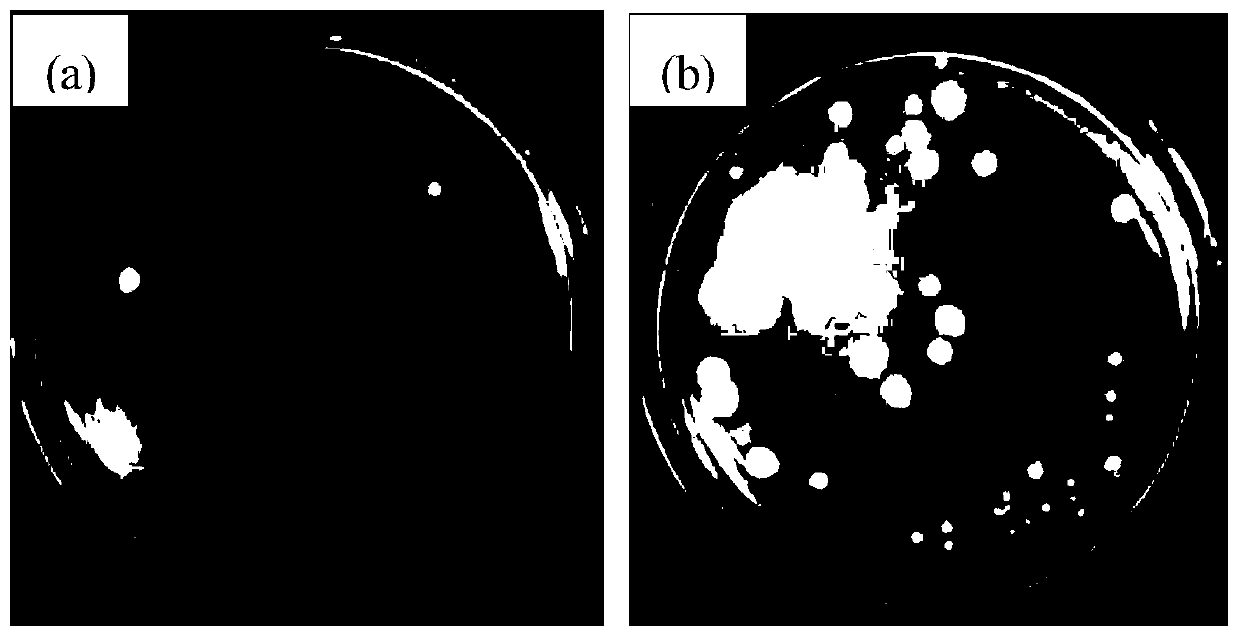

[0051] In this embodiment, the chemical composition of maraging antibacterial stainless steel is: C:0.49wt.%, Cr:16.42wt.%, Cu:3.34%, Mo:0.86wt.%, V:0.17wt.%, Mn : 0.82wt.%, Si: 0.76wt.%, O: 35ppm, N: 330ppm, S: 40ppm, P: 67ppm, and the balance is iron.

[0052] In this example, the heat treatment process after cold rolling: first, quenching after holding at 1060°C for 40 minutes, then holding at 170°C for 120 minutes, then air cooling to room temperature, and finally aging at 510°C for 40 minutes, then air cooling to room temperature.

Embodiment 3

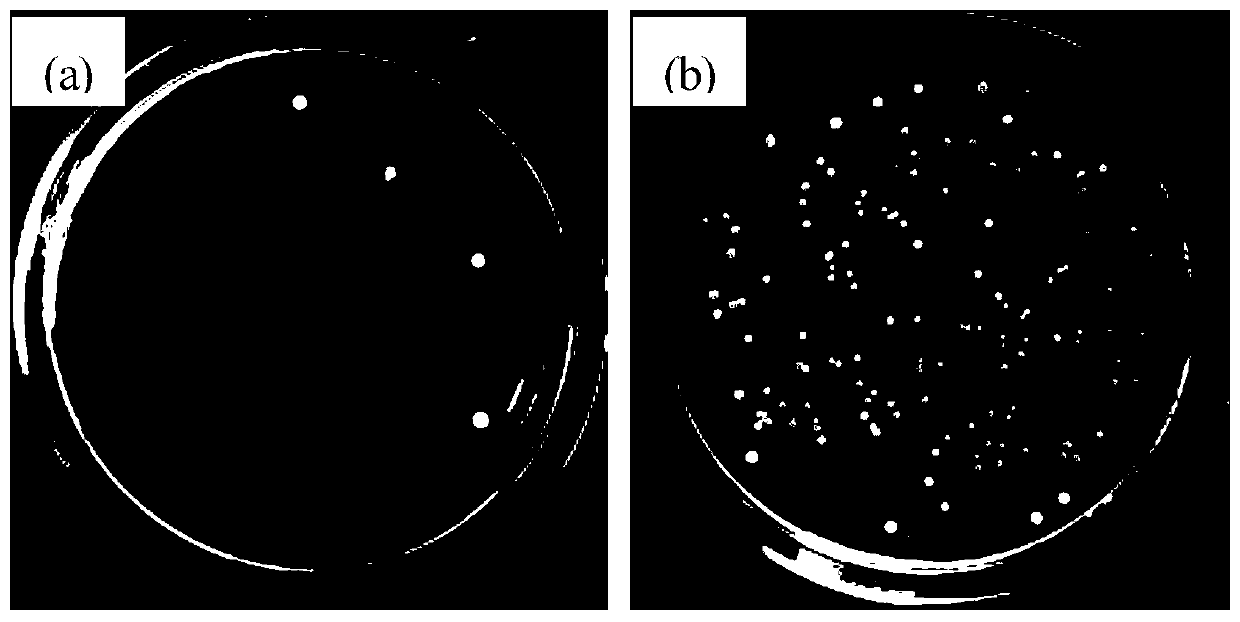

[0054] In this embodiment, the chemical composition of maraging antibacterial stainless steel is: C:0.43wt.%, Cr:15.07wt.%, Cu:2.81%, Mo:0.57wt.%, V:0.15wt.%, Mn : 0.52wt.%, Si: 0.48wt.%, O: 28ppm, N: 245ppm, S: 50ppm, P: 52ppm, and the balance is iron.

[0055] In this example, the heat treatment process after cold rolling: first, quenching after holding at 1030°C for 50 minutes, then holding at 180°C for 180 minutes, then air cooling to room temperature, and finally aging at 520°C for 50 minutes, then air cooling to room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com