Air source heat pump single-layer or multi-layer centralized placement system

An air source heat pump, single-layer technology, applied in heat pumps, pump devices, pumps, etc., can solve the problems of cross-infection of air in and out, affecting air heat exchange efficiency, etc., to save floor space, large heat exchange temperature difference, and contain the impact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

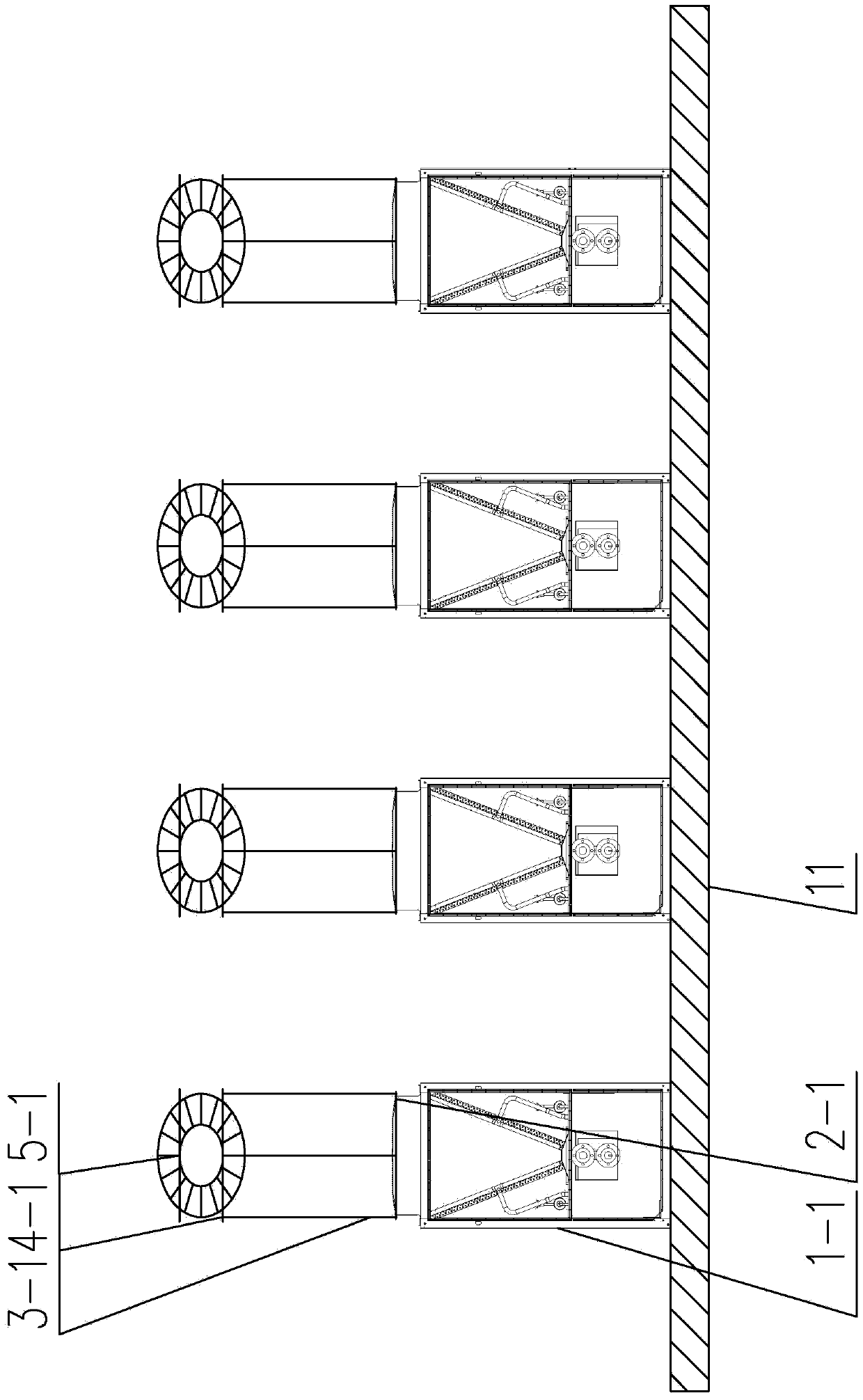

[0027] Specific implementation mode one, such as figure 1 As shown, a single-layer centralized placement system for air source heat pumps in this embodiment consists of an air source heat pump unit 1-1, an axial flow fan 2-1, a pipe section 3-1, and an air duct outlet 4 -1 and wind cap one 5-1, the air source heat pump unit one 1-1 is connected with the axial flow fan one 2-1, and the axial flow fan one 2-1 is connected with the pipe section one 3-1; the pipe section one The other end of the 3-1 is connected to the air outlet 4-1 of the air duct, and the air cap 5-1 is arranged on the upper part of the air outlet 4-1 of the air duct. Air source heat pump unit one 1-1, axial flow fan one 2-1, pipe section one 3-1, air duct outlet one 4-1 and air cap one 5-1 form the air duct device A1. Multiple air duct devices A1 are placed on a single-layer welded steel frame 11 . The beneficial effect of this embodiment is that air ducts are used to exhaust air independently, effectively p...

specific Embodiment approach 2

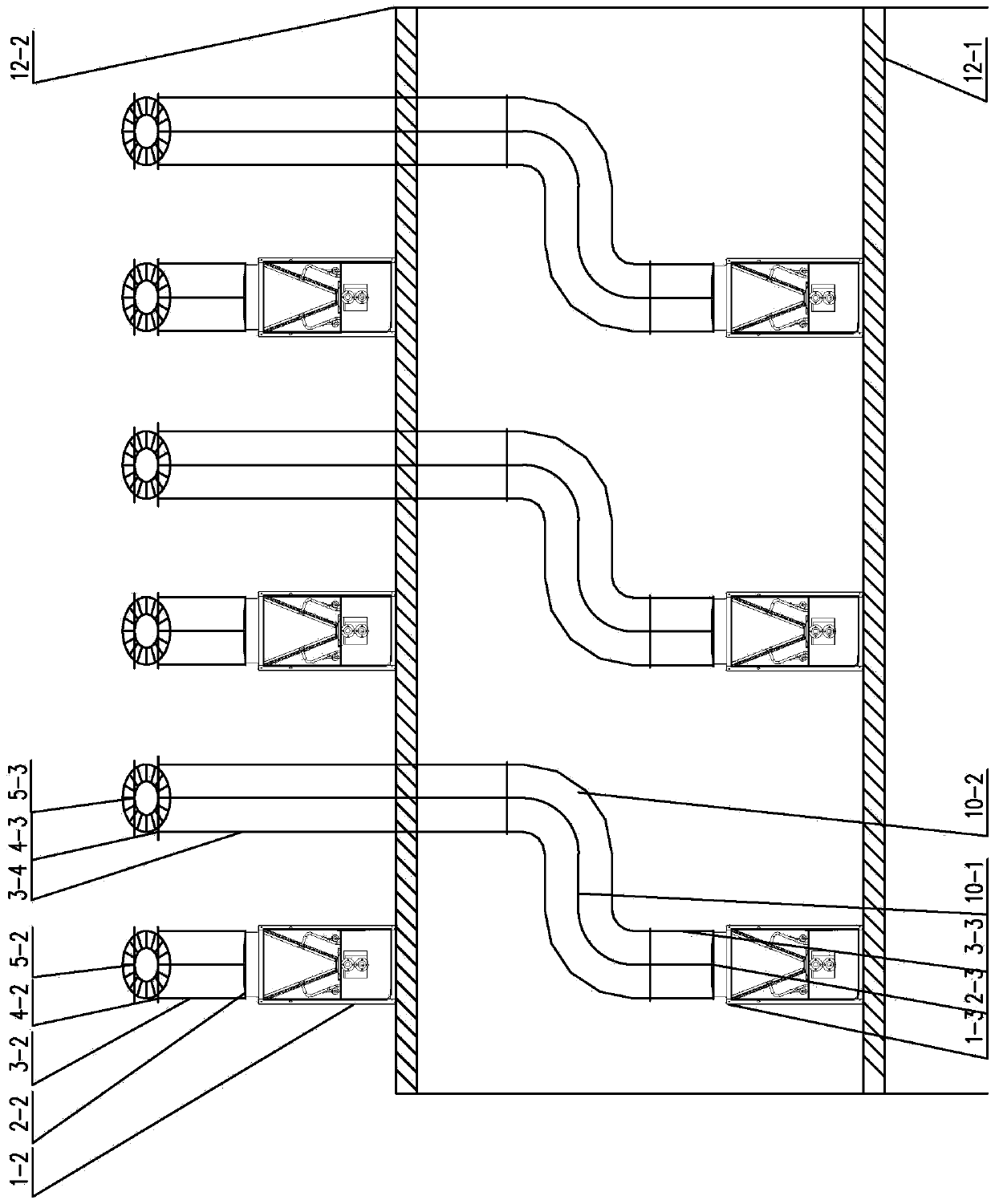

[0028] Specific implementation mode two, such as figure 2 As shown, a double-layer centralized placement system for air source heat pumps in this embodiment consists of air source heat pump unit two 1-2, air source heat pump unit three 1-3, axial flow fan two 2-2, axial flow fan Three 2-3, pipe section two 3-2, pipe section three 3-3, pipe section four 3-4, air duct elbow one 10-1, air duct elbow two 10-2, air duct outlet two 4-2, Air pipe outlet three 4-3, wind cap two 5-2 and wind cap three 5-3, the air source heat pump unit two 1-2 is connected with axial flow fan two 2-2, axial flow fan two 2- 2 is connected with the second pipe section 3-2; the other end of the second pipe section 3-2 is connected with the second air outlet 4-2 of the air duct, and the second air cap 5-2 is arranged on the upper part of the second air outlet 4-2 of the air duct. Air source heat pump unit 2 1-2, axial flow fan 2 2-2, pipe section 2 3-2, pipe section 2 3-2, air duct outlet 2 4-2, and air ...

specific Embodiment approach 3

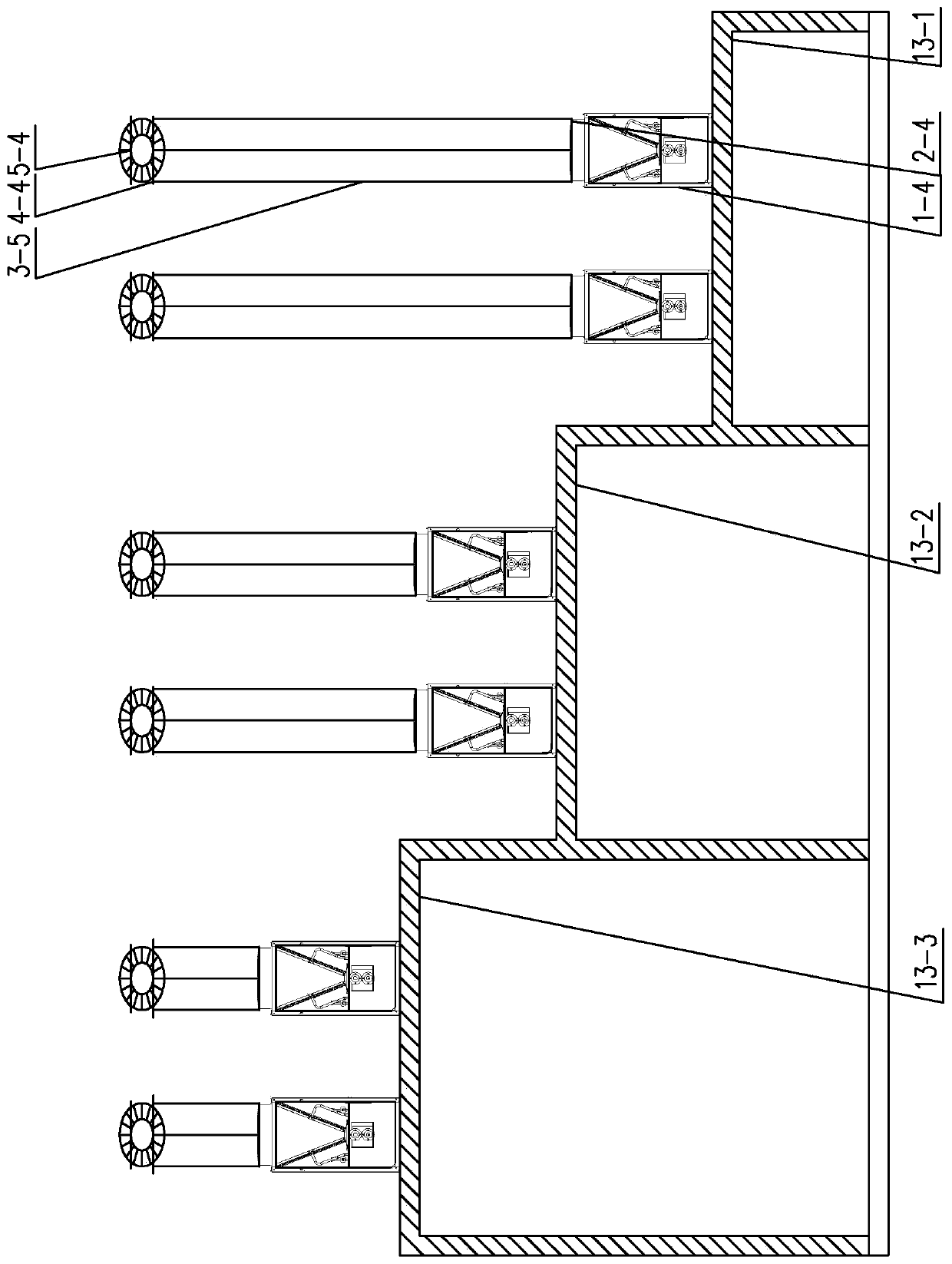

[0029] Specific implementation mode three, such as image 3 As shown, an air source heat pump multi-layer centralized placement system in this embodiment is composed of air source heat pump unit 4 1-4, axial flow fan 4 2-4, pipe section 5 3-5, air duct outlet 4 4- 4 and wind cap 4 5-4, the air source heat pump unit 4 1-4 is connected with axial flow fan 4 2-4, axial flow fan 4 2-4 is connected with pipe section 5 3-5; pipe section 5 3 The other end of -5 is connected to the air outlet 4-4 of the air duct, and the air cap 4 5-4 is set on the upper part of the air outlet 4-4 of the air duct; the air source heat pump unit 4 1-4, and the axial flow fan 4 2-4 , pipe section five 3-5, air duct air outlet four 4-4 and wind cap four 5-4 form the air duct device A3. The air duct device B2 and the air duct device C are connected in the same way as the air duct device A3; the air duct device A3 is placed on the multi-layer welded steel frame 13-1, and the air duct device B2 is placed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com