A Predictive Control Method for DC Converter

A technology of DC converter and predictive control, which is applied in the direction of converting DC power input to DC power output, control/regulation system, DC network circuit device, etc., and can solve the error between output results and target results, poor system robustness, and dynamic characteristics To achieve the effect of simplifying calculations, accurate observation results, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

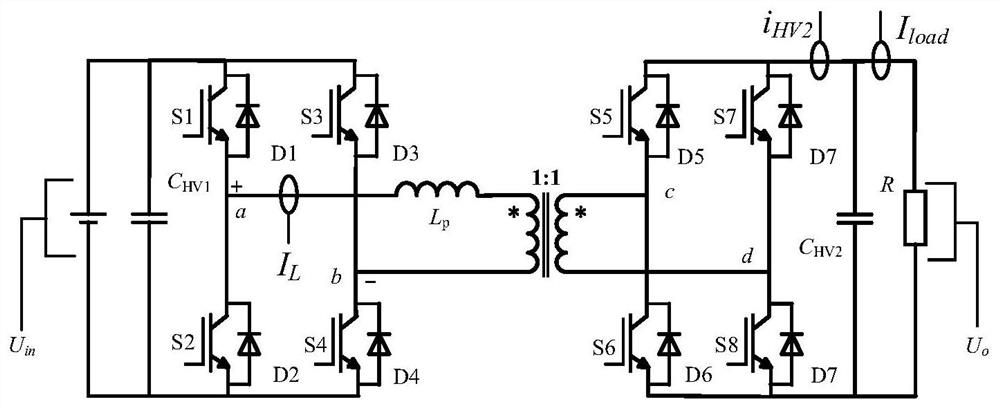

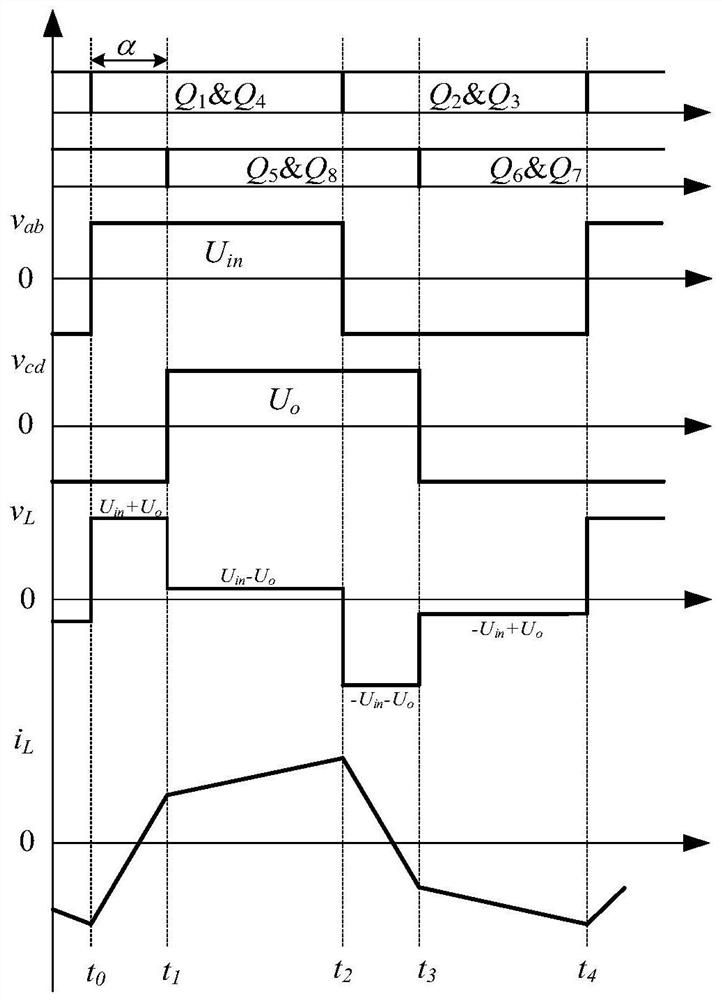

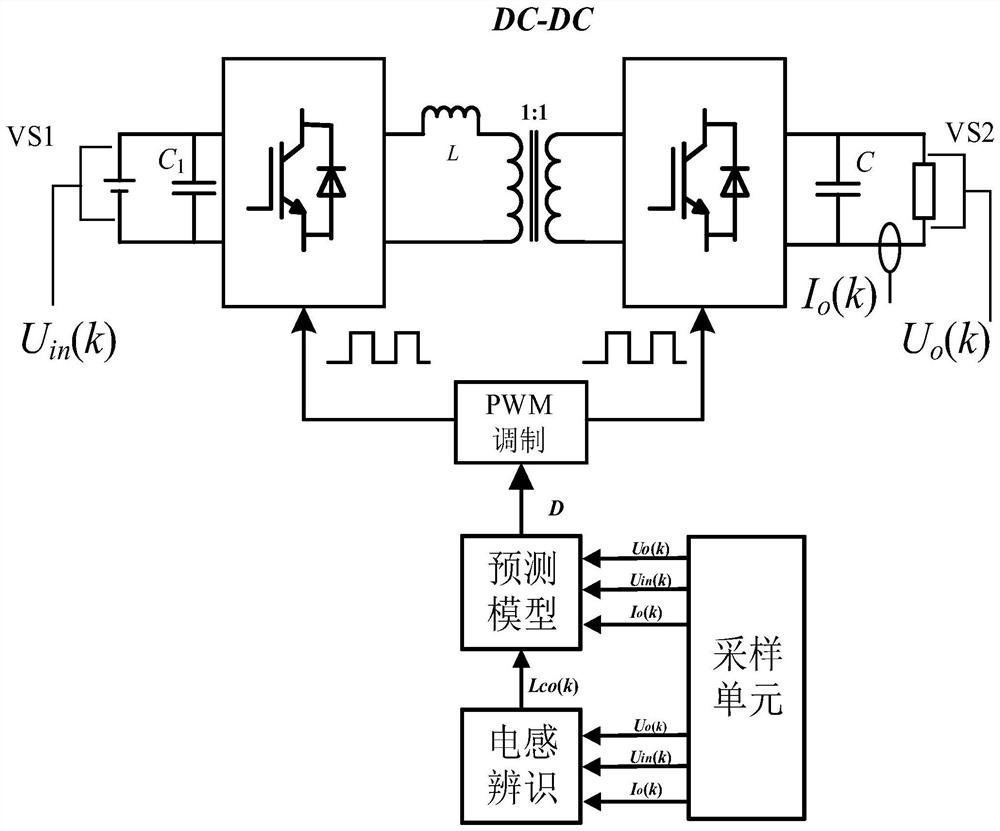

[0038] The present invention will be further described below with reference to the accompanying drawings.

[0039] The invention provides a direct current converter predictive control method based on resonant inductance parameter identification. In the control method of the present invention, the output state differential equation established by the DC converter circuit model is firstly processed, and then the discretization process is performed to obtain a prediction model. List several control variables that may appear in the next control cycle, bring them into the prediction model to obtain a number of predicted output results, and obtain the optimal output results through the cost function comparison, and then lock the optimal control variables at the next moment; in order to solve the actual resonance of the converter The inductance value is easy to change, which makes the predicted model inductance value mismatch with the actual inductance value. The present invention ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com