Roller design method suitable for COF tin baking

A design method and roller technology, applied in the secondary processing of printed circuits, electrical components, printed circuit manufacturing, etc., can solve the problems of increased raw material costs, increased operating steps, and increased production costs for isolation belts, achieving good baking effects, Reduced operation steps, perfect transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

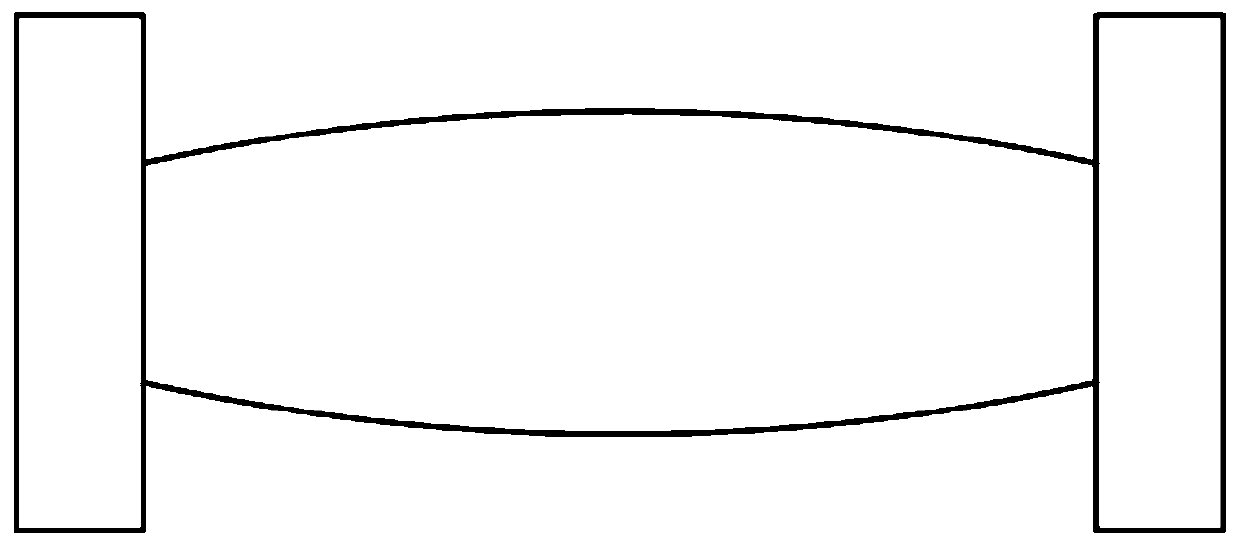

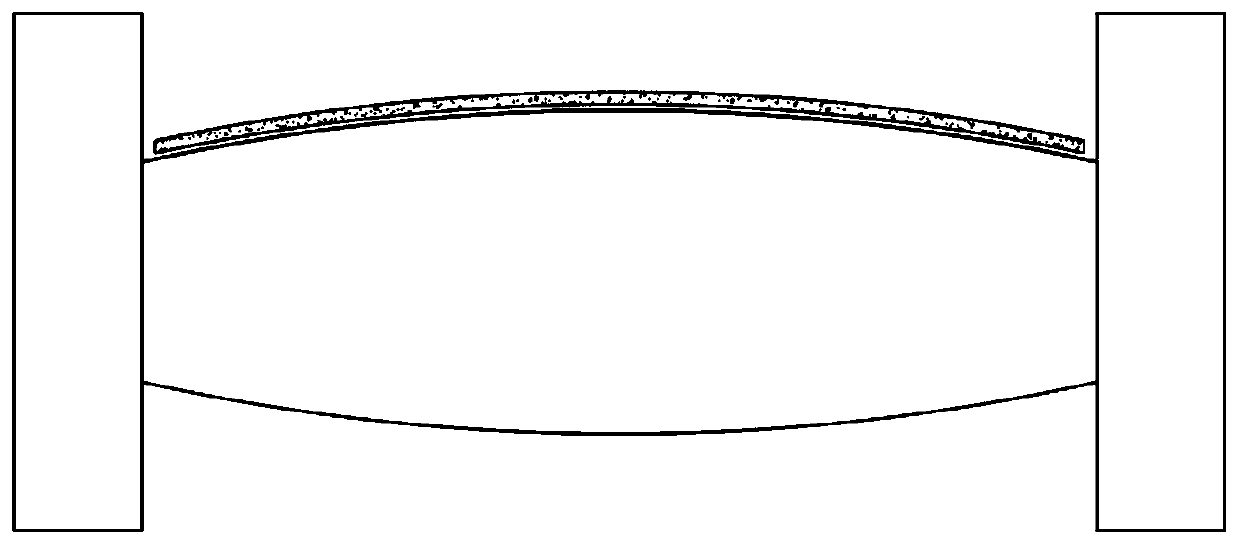

[0022] like Figure 1-2 As shown, the embodiment of the present invention provides a roller design method suitable for COF tin baking, including the following steps:

[0023] S1. Determine the baking temperature in the COF tin linear baking oven, observe and record the deformation degree of the product at different temperatures in the baking oven;

[0024] S2. On the basis of the normal roller, according to the degree of deformation of the product, the roller has an arc, and the length of the roller is reduced at the same time;

[0025] S3. When the product is conveyed in a straight line, ensure that the bending amount of the product is consistent with the curvature of the roller, and that the product can be closely attached to the roller when conveying.

[0026] The product in the present invention is heated evenly, has good baking effect, and reduces the operation steps in the prior art and reduces the production cost of the enterprise.

[0027] The diameter of the middle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com