Dyeing machine for food processing

A food processing and dyeing machine technology, applied in food forming, food science, application, etc., can solve the problems of small dyeing area and inability to adapt well, and achieve the effect provided by the dyeing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

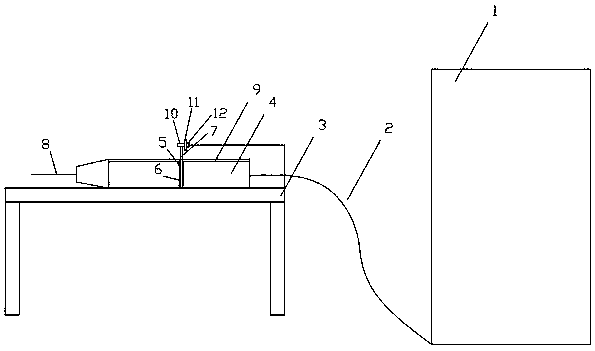

[0016] A food processing dyeing machine comprises a dyeing container 1, the bottom of the dyeing container 1 is connected with a conveying pipe 2, and the conveying pipe 2 is connected with a dyeing fixing frame 3, and one end of the dyeing fixing frame 3 is provided with a dyeing measuring cylinder 4. A push plate 5 is arranged in the dyeing measuring cylinder 4, and a draw-in groove is arranged in the described pushing plate 5, and a dividing plate 6 is arranged in the drawing-in groove, and a guide rod 7 is arranged on the top of the dividing plate 6, and the dyeing measuring cylinder 4 The tail is provided with 8 dyeing needles. This application can carry out needle tube type injection dyeing for the dyeing needs of small areas, and in the process of dyeing, it can be driven by the horizontal cylinder 12 to make the push plate 5 in the dyeing measuring cylinder 4 do horizontal reciprocating actions to realize the dyeing process. The pushing of coloring agent, and draw-in g...

Embodiment 2

[0018] A food processing dyeing machine comprises a dyeing container 1, the bottom of the dyeing container 1 is connected with a conveying pipe 2, and the conveying pipe 2 is connected with a dyeing fixing frame 3, and one end of the dyeing fixing frame 3 is provided with a dyeing measuring cylinder 4. A push plate 5 is arranged in the dyeing measuring cylinder 4, and a draw-in groove is arranged in the described pushing plate 5, and a dividing plate 6 is arranged in the drawing-in groove, and a guide rod 7 is arranged on the top of the dividing plate 6, and the dyeing measuring cylinder 4 The tail is provided with 8 dyeing needles.

[0019] The dyeing cylinder 4 is provided with a guide groove 9, and the guide rod 7 passes through the guide groove 9.

[0020] A lift cylinder 10 is connected to the guide rod 7 .

[0021] The lifting cylinder 10 is connected with a fixed plate 11 , and the fixed plate 11 is connected with a horizontal cylinder 12 .

[0022] This application c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com