Semiconductor type gas sensor, multiple sensing device and recognition method of multiple sensing device

A gas sensor and multi-sensing technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of increased production cost, power consumption, inability to use PCB substrates, and difficulty in accurately detecting gases, so as to save production costs and reduce consumption Power and maintenance costs, effects of accurate gas detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following description will be made with reference to the accompanying drawings of embodiments of the present invention that can specifically achieve the above objects. In the description of the present embodiment, the same names and reference numerals are used for the same components, and additional description thereof will be omitted below.

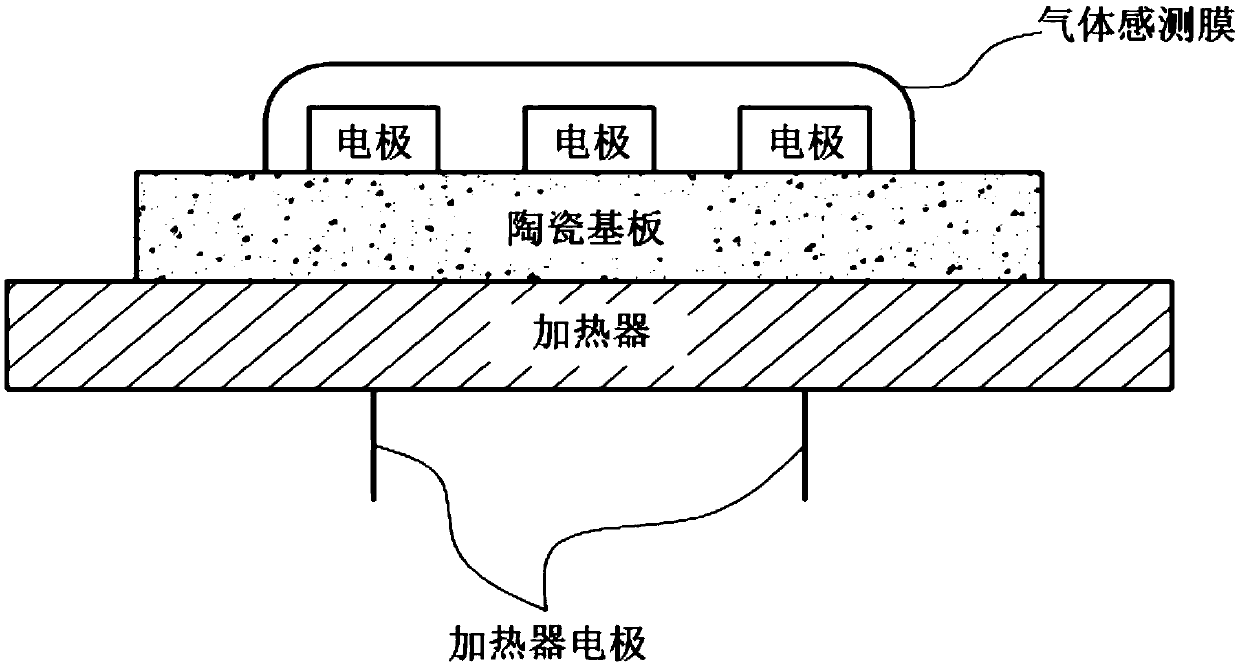

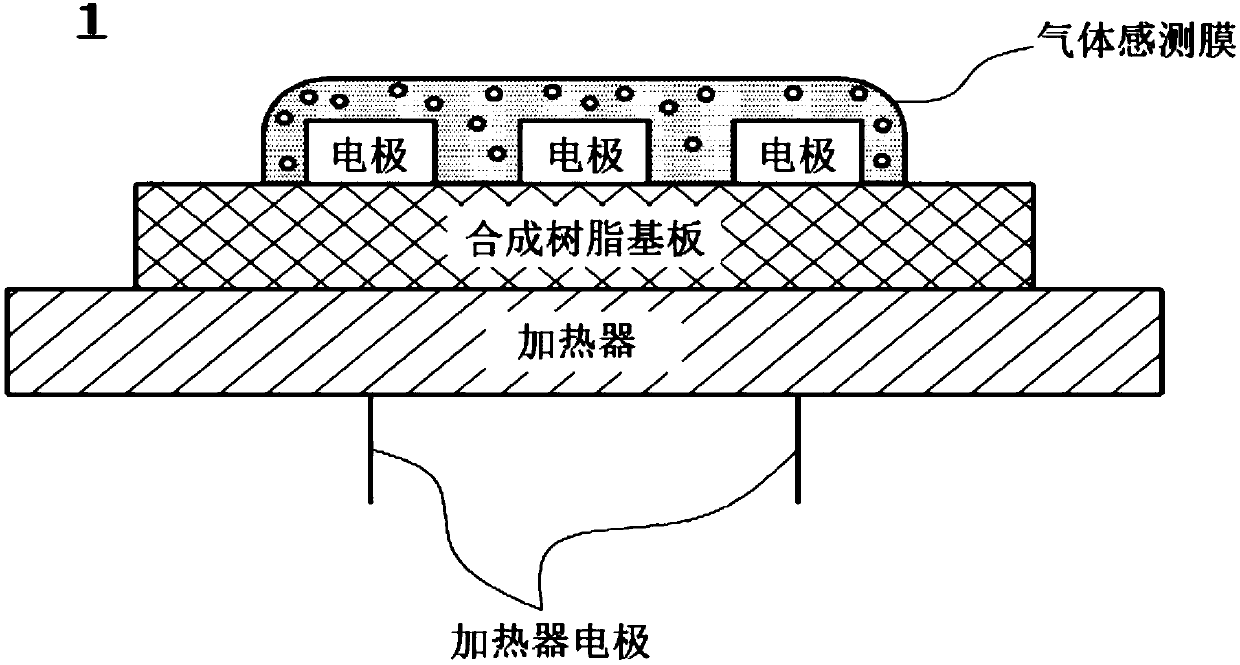

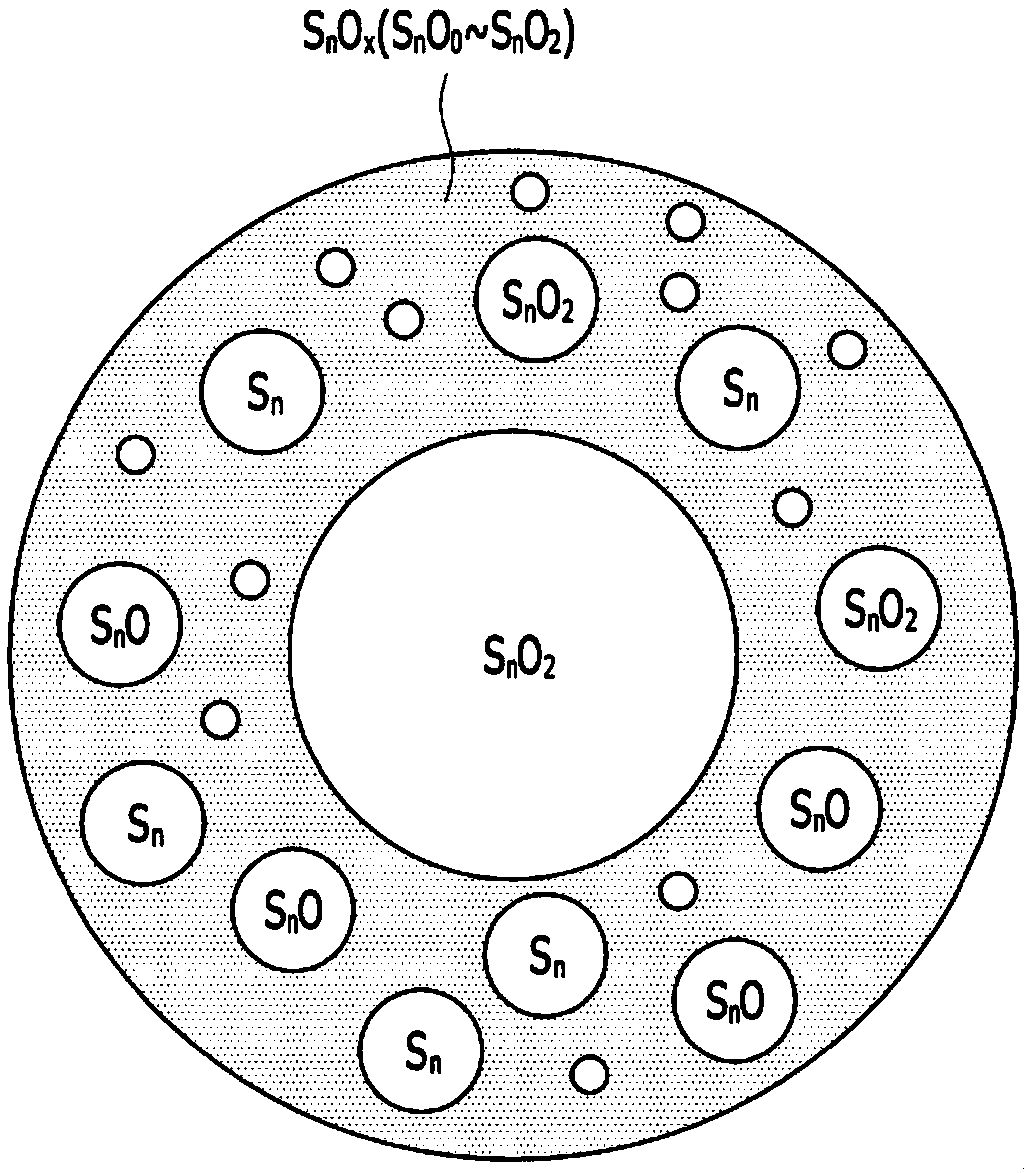

[0028] figure 2 is a cross-sectional view of the semiconductor-type gas sensor of the present invention, image 3 It is a schematic cross-sectional view of a detection substance used to form a gas-sensitive film in a semiconductor-type gas sensor of the present invention, Figure 4 It is a graph of the composition distribution of the detection substance used to form the gas-sensitive film in the semiconductor-type gas sensor of the present invention, Figure 5 It is a graph comparing the change with time of the resistance value of the semiconductor-type gas sensor of the present invention and the conventional semiconductor-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com