Progressive-ploughing-depth ploughing machine

A progressive, raking machine technology, applied in the poultry industry, poultry cages or houses, animal husbandry and other directions, can solve the problems of large raking load, dead bed of bacteria, and labor consumption, etc., and achieves improved raking speed, The effect of fully fermenting and preventing the hardening of the cushion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

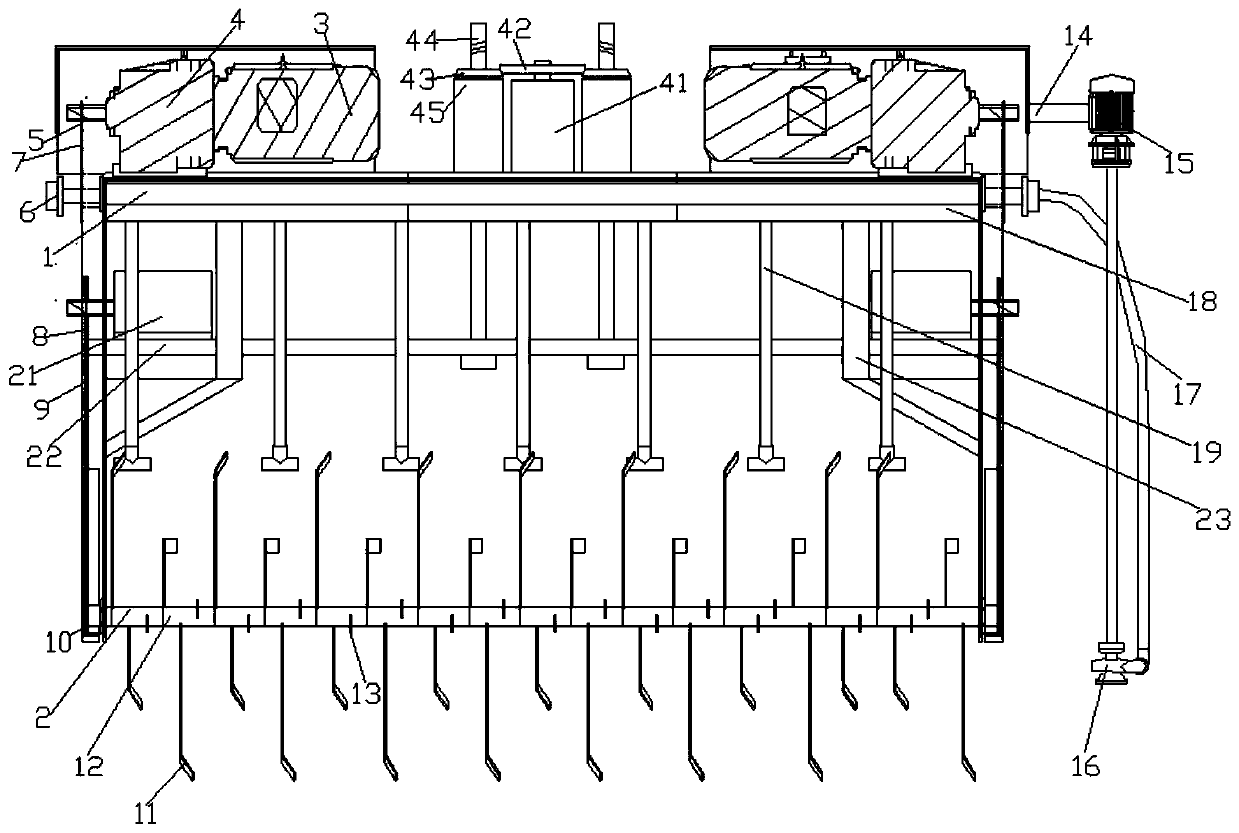

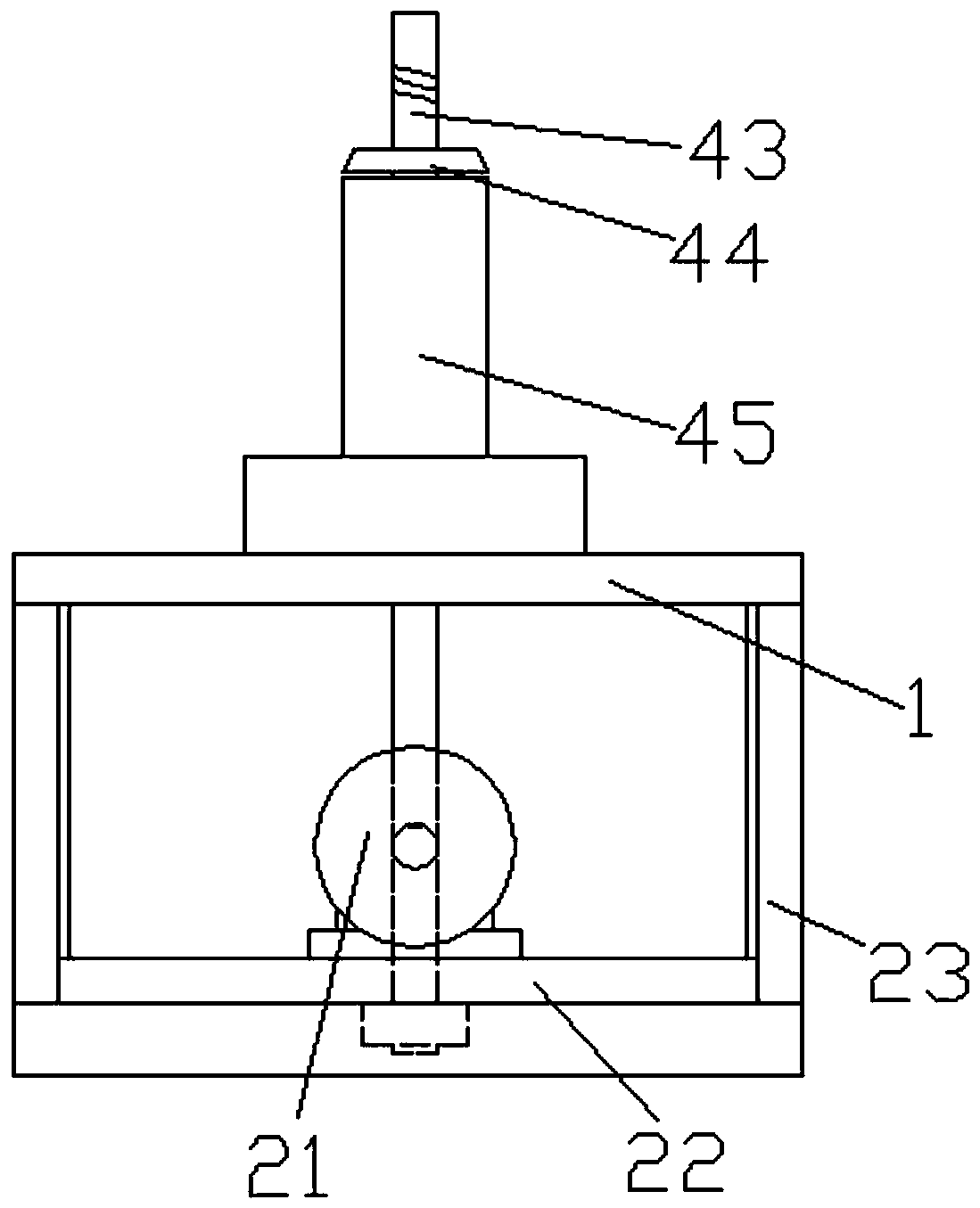

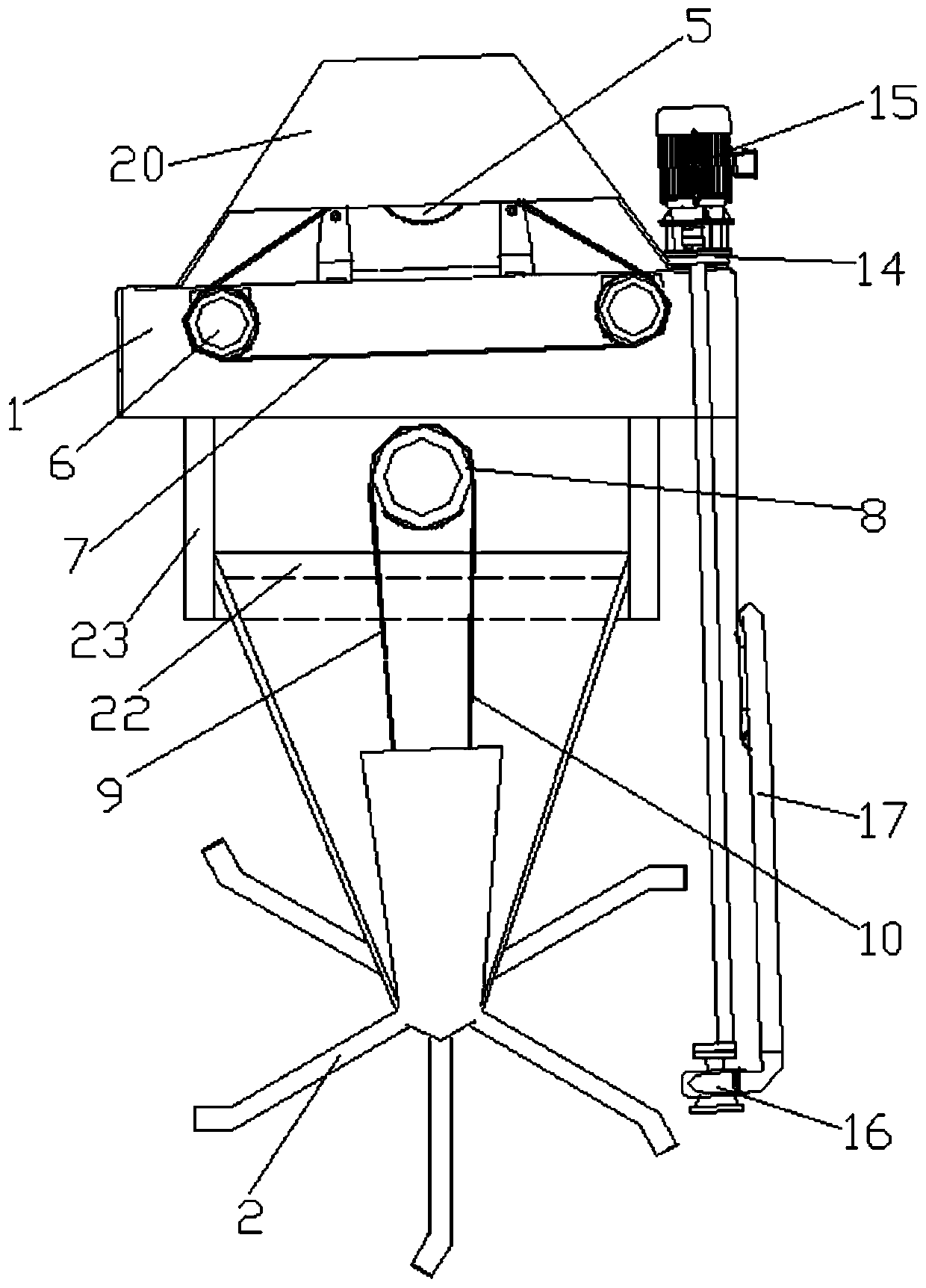

[0027] Figure 1-6 Schematic diagram of the structure of the progressive rake turning machine of the present invention, a progressive rake turning machine of the present invention, comprising a frame 1 horizontally installed in the fermentation tank and a rake turning frame 2 arranged below the frame 1 , the frame 1 is provided with a walking synchronous motor 3 near both ends of the fermentation tank, the motor shaft of the walking synchronous motor 3 is connected with a driving wheel 5, and the side wall of the frame 1 is provided with a pair of horizontally arranged The traveling wheel assembly, 1 pair of the traveling wheel assembly and the driving wheel 5 are ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com