Motor controller

A motor controller and chassis technology, applied in the direction of AC motor control, control system, electromechanical devices, etc., can solve the problem that the motor controller and the motor system fail to realize the common water channel, the common junction box, and the failure to further miniaturize and integrate problems such as miniaturization, to achieve the effect of miniaturization of the overall shape and convenient installation and layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the embodiments in the accompanying drawings, but this does not constitute any limitation to the present invention.

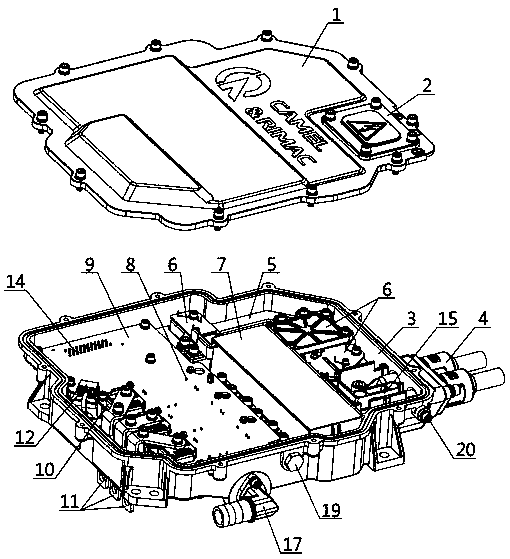

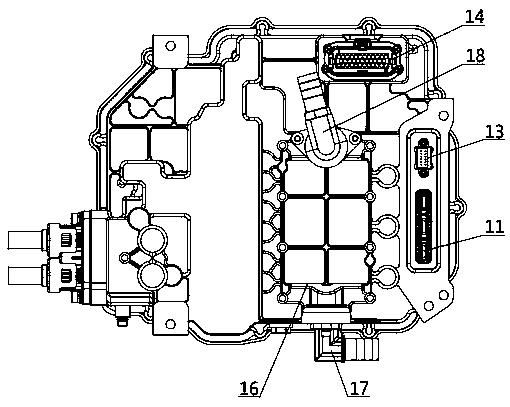

[0012] Such as figure 1 with figure 2 As shown, a motor controller provided by the present invention includes an upper cover 1 and a casing 3, the casing 3 and the upper cover 1 are fixedly connected by bolts, and a high-voltage DC plug-in is plugged outside the casing 3 4 is used to provide power supply input to the controller. There are two conductive copper bars 5, one positive and one negative, at least one filter unit 6, one capacitor 7, and one integrated power module (i.e., IGBT module 8) installed inside the casing 3 And an integrated circuit board 9, the positive and negative conductive copper bars 5 extend along the outline of the casing 3, one end of which is connected to the positive and negative terminals of the high-voltage DC plug-in 4 correspondingly, an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap