Piston with structured design

A technology of structural form and piston, which is applied in the field of piston with structural form, can solve the problems of weight reduction, durability or strength loss, piston weight is not optimal, etc., and achieve the effect of weight saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

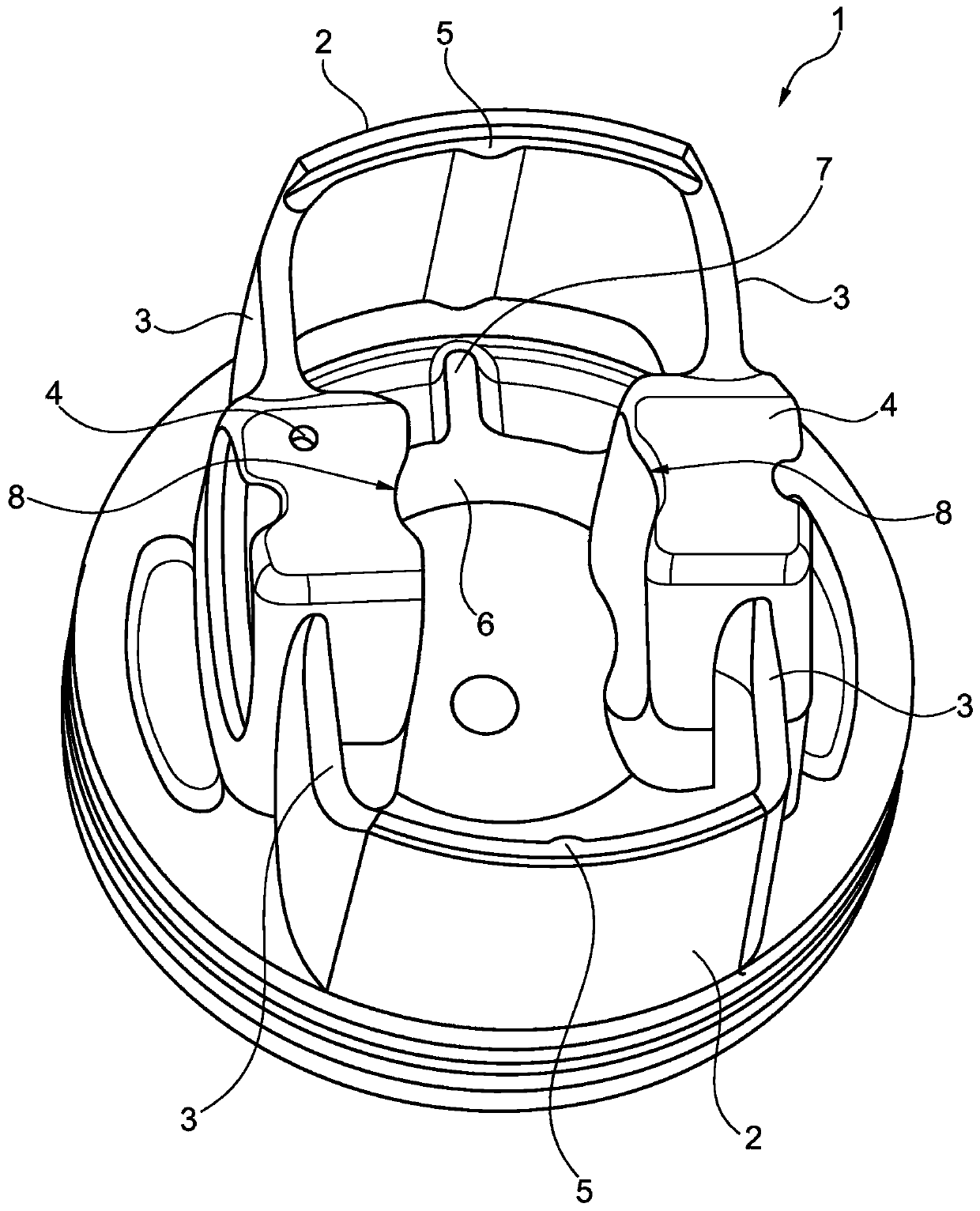

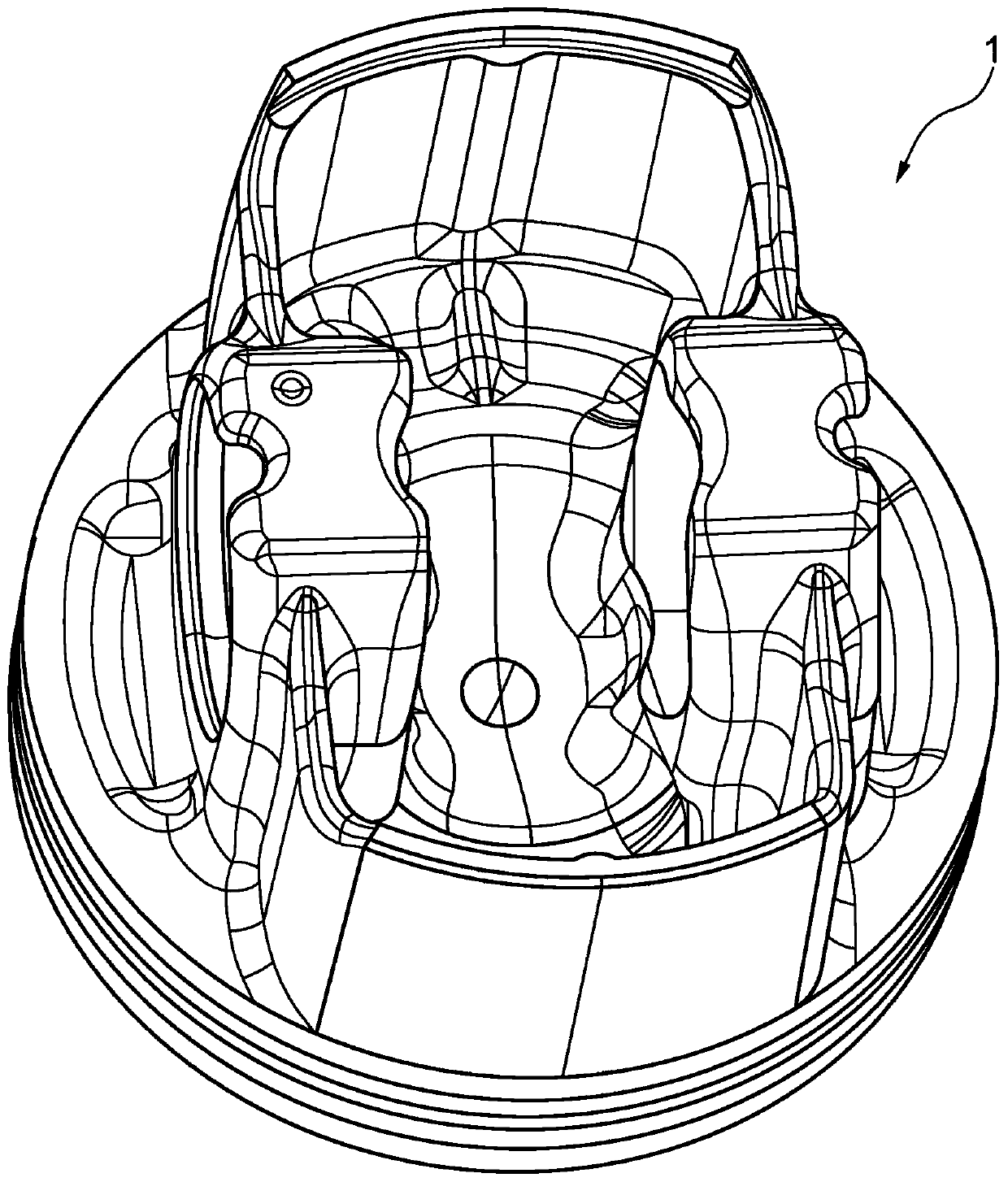

[0014] figure 1 The piston 1 is shown from below in a three-dimensional view, wherein the opposite load-bearing skirt section 2 is designated with the reference numeral 2, the connecting wall connecting the opposite load-bearing skirt sections 2 to one another Indicated with reference numeral 3 . The connecting walls 3 each extend from the piston pin hub 4 in the direction of the side edge of the load-bearing skirt wall section 2 .

[0015] It should be pointed out at this point that the method known from patent document DE 10 2004 031 513 A1 can be used for the production of the piston 1 , but it does not have to be used. Because the piston base body of the finished piston 1 is formed after forging, it should be noted that the participating elements (such as the skirt wall section 2, connecting wall 3, piston pin hub 4 and the like) have the required pull-out for the forging process. Die slope. Besides a forging process, production by a casting process is obviously also c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com