Automatic exhaust type fire arrester for positive pressure cabinet

An automatic exhaust and flame arrester technology, which is applied in fire rescue and other directions, can solve the problems of affecting the life of the solenoid valve, high noise, and high price of the explosion-proof solenoid valve, and achieve the effect of automatic pressure relief and exhaust and fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

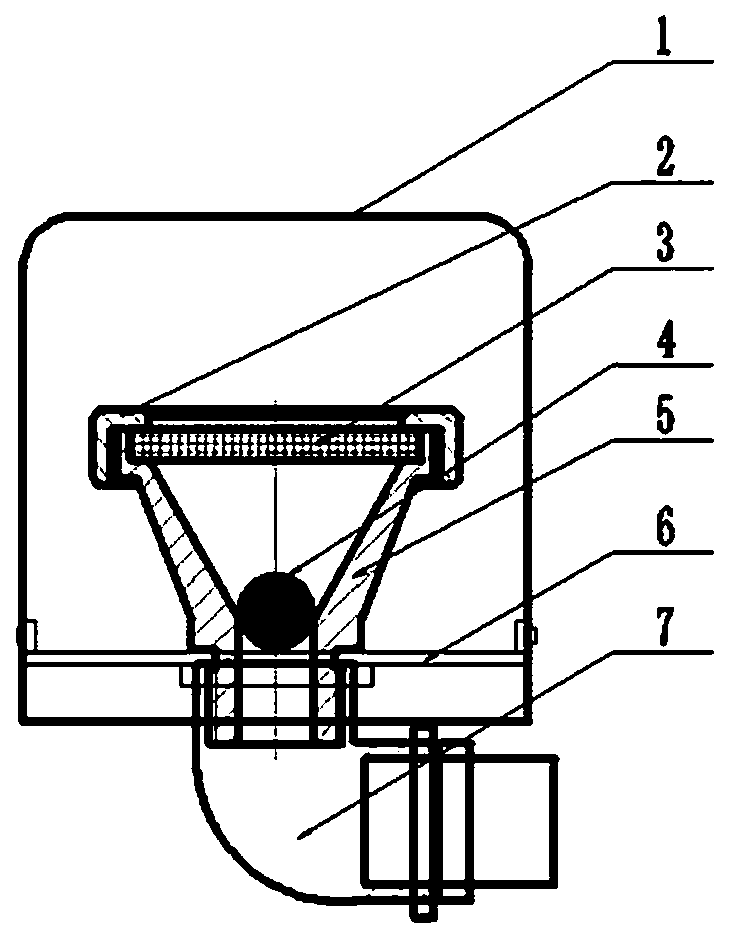

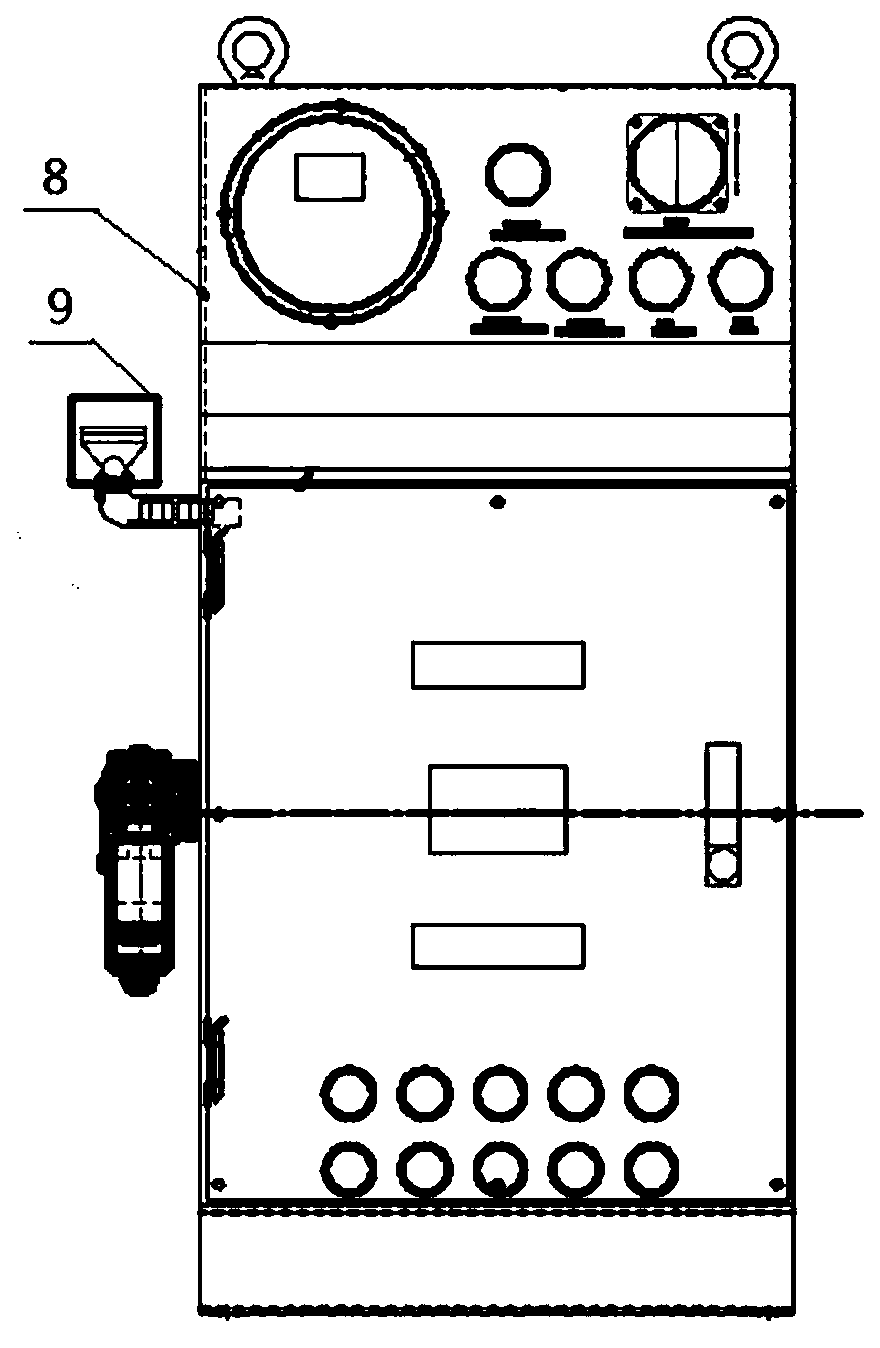

[0012] The automatic exhaust type flame arrester for the positive pressure cabinet of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0013] see figure 1 and figure 2 , the automatic exhaust type flame arrester for the positive pressure cabinet of the present invention includes a right-angle elbow 7 connected to the positive pressure cabinet 8 at one end, and a cone-shaped body 5 made of stainless steel is embedded in the other end port of the right-angle elbow 7, The inner cavity of the conical body 5 is in an inverted conical shape and communicates with the right-angle elbow 7 . A gravity ball 4 is placed at the lower opening of the cone body 5. The gravity ball 4 is formed of a flame-retardant material glass fiber reinforced unsaturated polyester. The weight and outer diameter of the gravity ball are based on the pressure of the positive pressure chamber and the diameter of the gas path. It is calculated according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com