Drying treatment device for lithium battery recovery

A drying treatment, lithium battery technology, applied in drying gas arrangement, drying solid materials, drying chamber/container, etc., can solve the problems of general drying effect, uniformity of material drying, easy accumulation of materials, etc. The effect of drying, increasing wind speed and improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

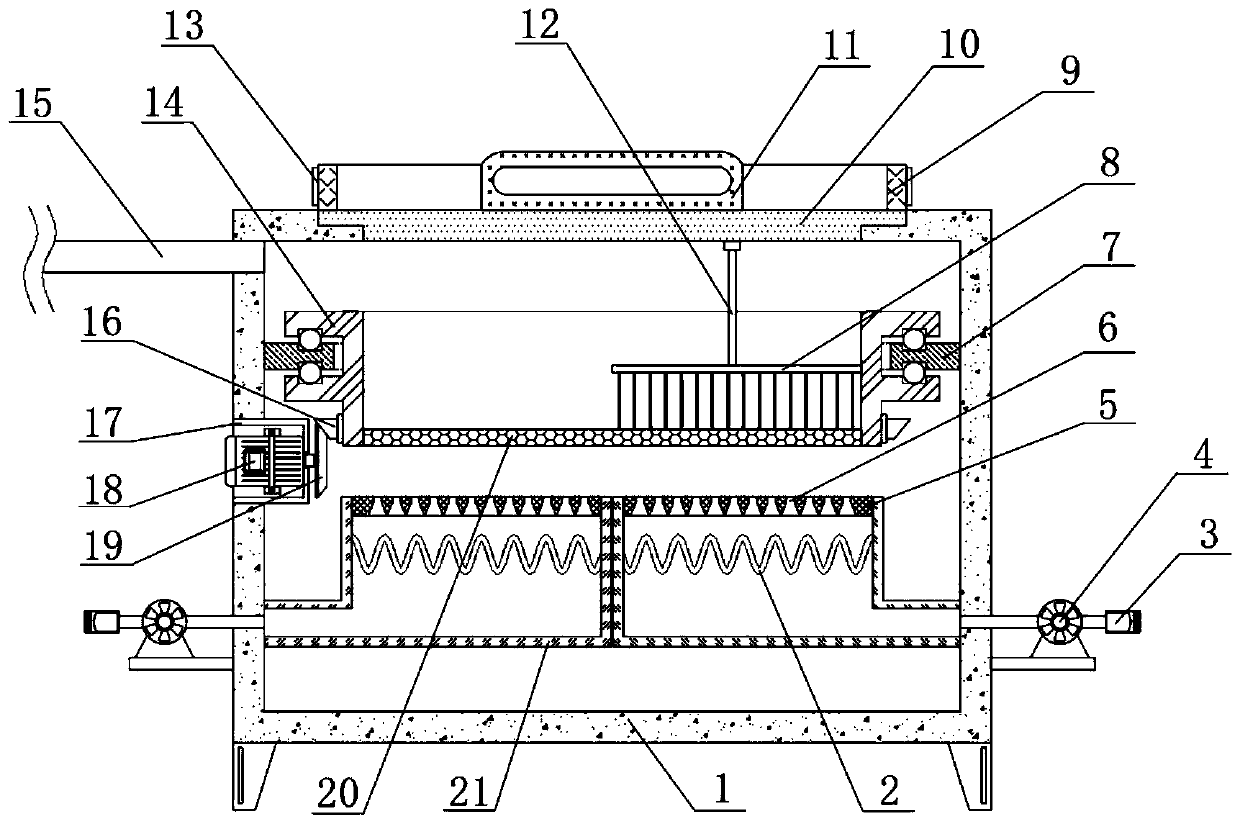

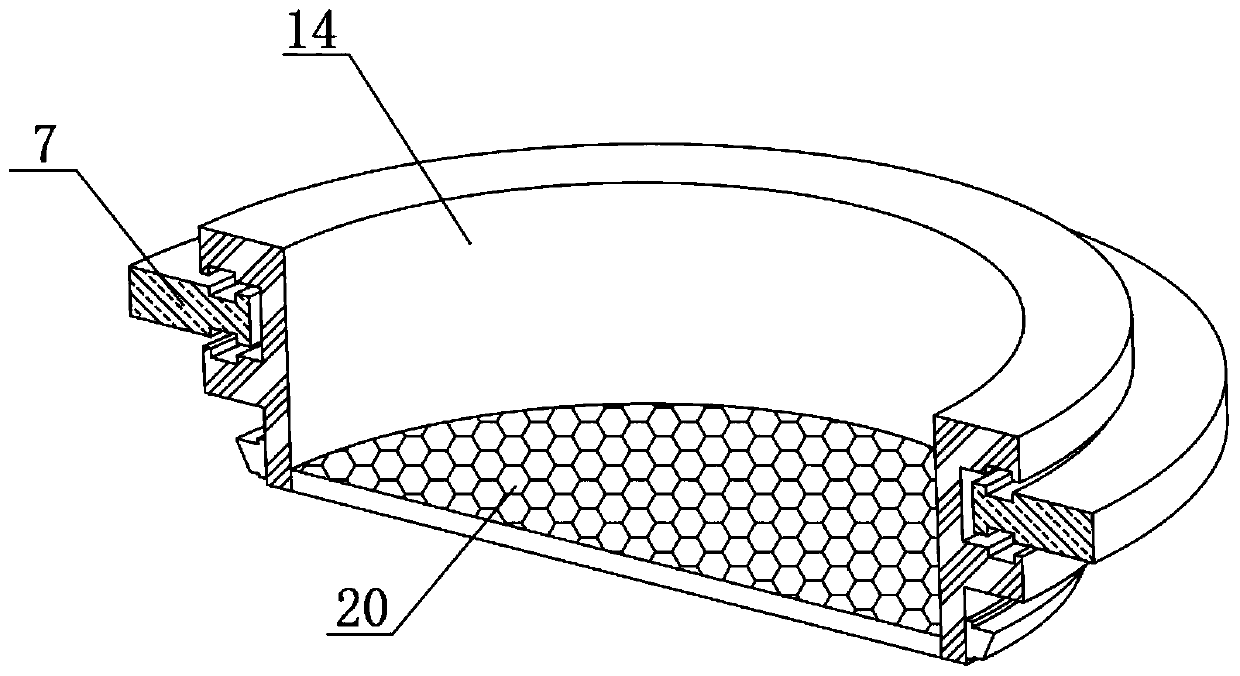

[0029] A dry treatment device for lithium battery recycling, such as figure 1 , figure 2 and Figure 4 As shown, it includes a cylinder 14 and a box body 1 with legs welded at the four corners of the bottom. Both sides of the bottom end of the box body 1 are equipped with a hot air mechanism, and one end of the inner wall of the box body 1 is welded with a fixed ring 7. The fixed ring 7 and The opposite sides of the cylinder 14 are provided with annular grooves, and the inner walls of the corresponding two annular grooves are rollingly connected with balls distributed equidistantly. The bottom end of the cylinder 14 is fixed with a mesh plate 20 by bolts, and the box 1 is close to the cylinder. One side of the body 14 is equipped with a drive mechanism, the top of the box body 1 is connected with a cover plate 10 by threads, and a connecting rod 12 is welded on one side of the bottom outer wall of the cover plate 10, and a toggle rod is welded horizontally at the end of the ...

Embodiment 2

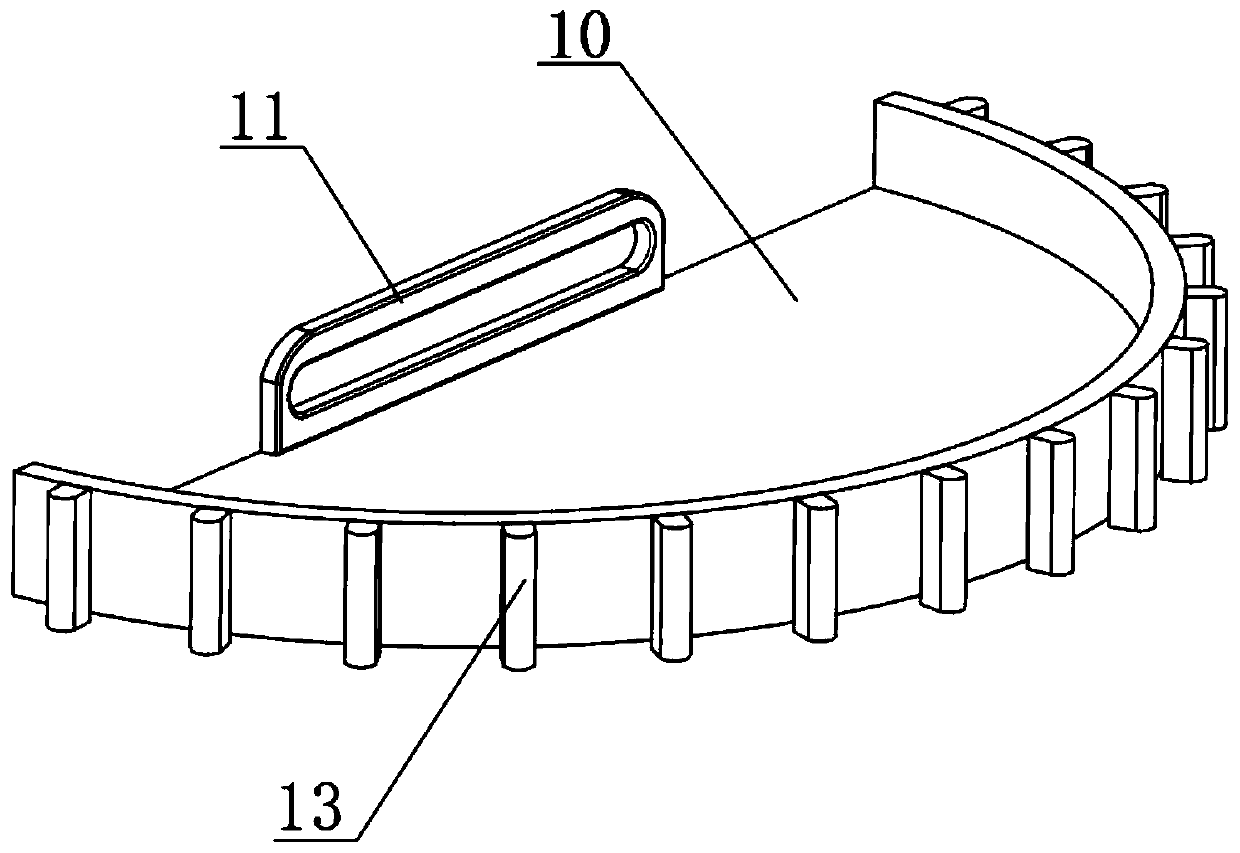

[0038] A dry treatment device for lithium battery recycling, such as figure 1 and image 3 As shown, in order to facilitate the operator to open the cover plate 10; this embodiment makes the following improvements on the basis of embodiment 1: the edge of the top outer wall of the cover plate 10 is welded with a surrounding edge 9, and the outer wall of the surrounding edge 9 is welded with equidistant Distribution of key strips13.

[0039] When this embodiment is in use, the operator can turn the cover 10 by turning the key bar 13 on the surrounding edge 9, so as to facilitate the rotation and loading of the cover 10, and finally achieve the purpose of facilitating the operator to open and close the cover 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com