Electronic component

A technology of electronic components and external electrodes, which is applied in the direction of electrical components, circuits, parts of fixed capacitors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Exemplary embodiments of the present disclosure will now be described in detail below with reference to the accompanying drawings.

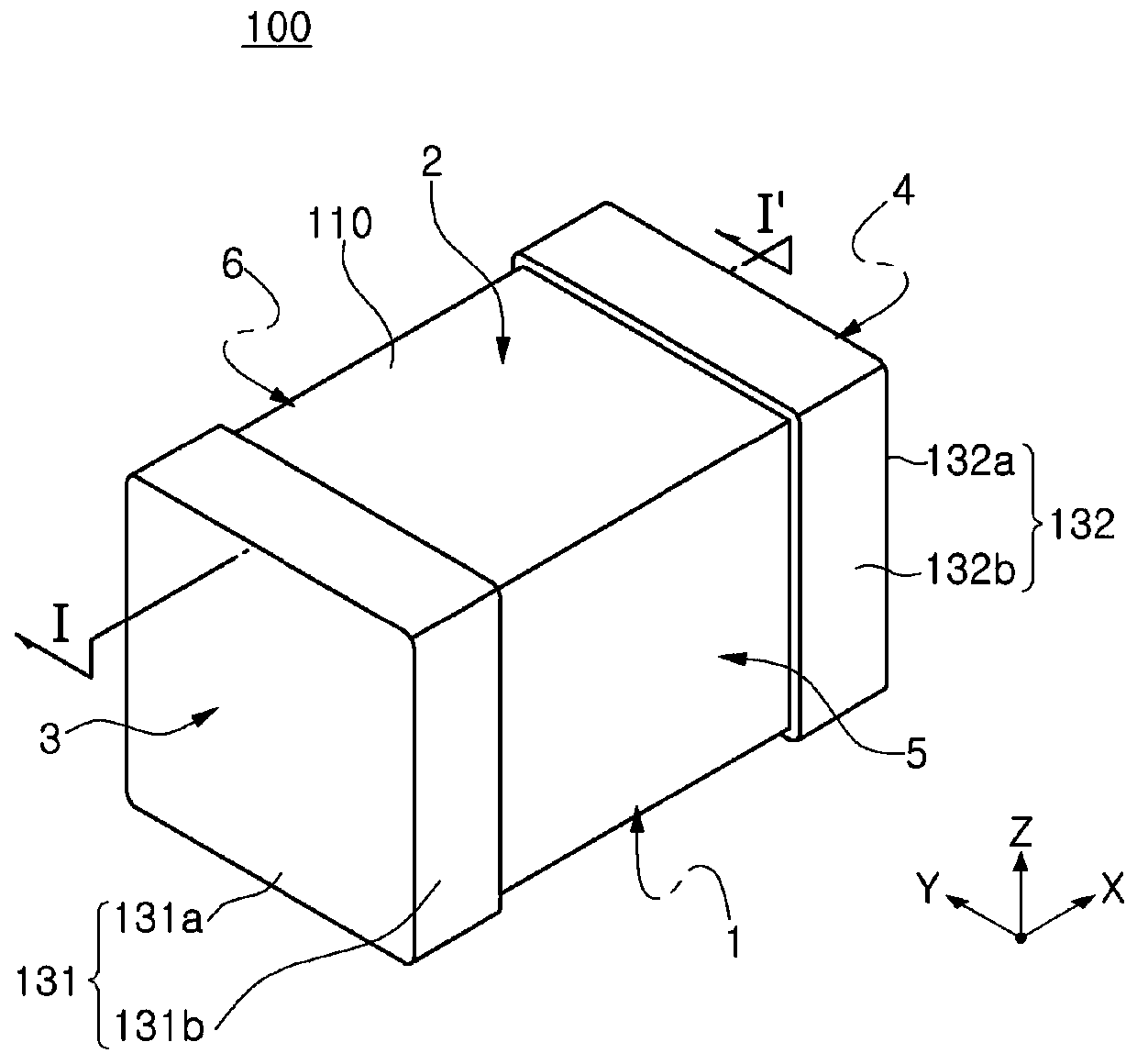

[0037] Directions will be defined to clearly describe exemplary embodiments in the present disclosure. X, Y and Z in the drawings refer to the length direction, width direction and thickness direction of the multilayer capacitor and electronic component, respectively.

[0038] Here, the Z direction refers to the stacking direction along which the dielectric layers are stacked in this exemplary embodiment.

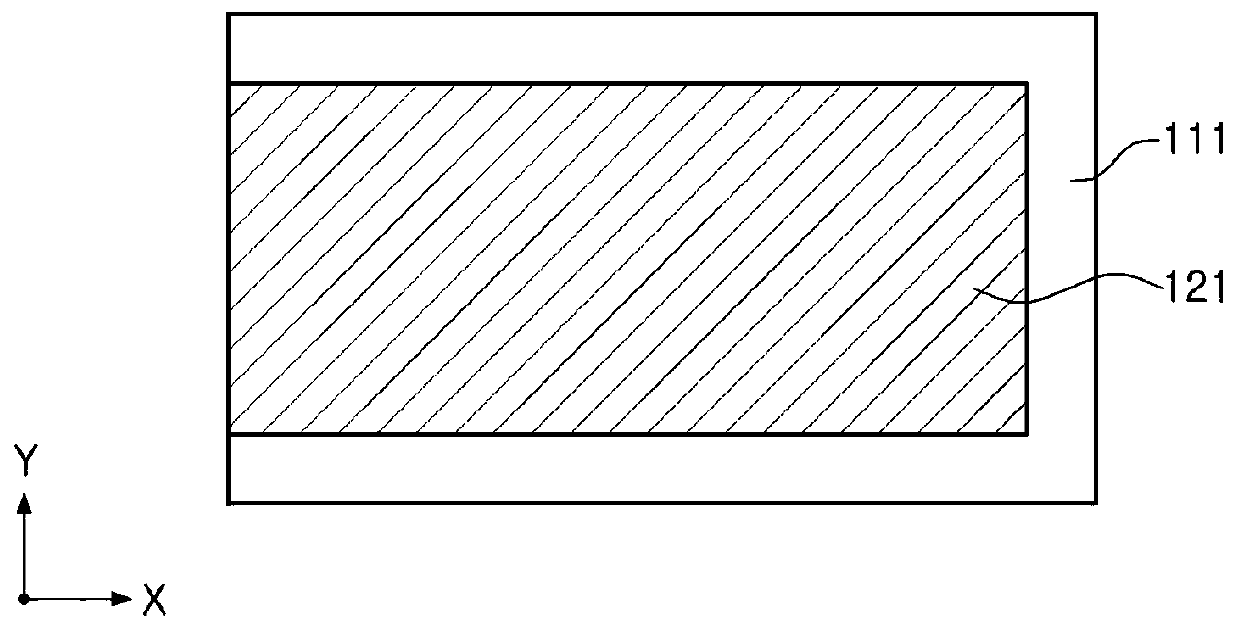

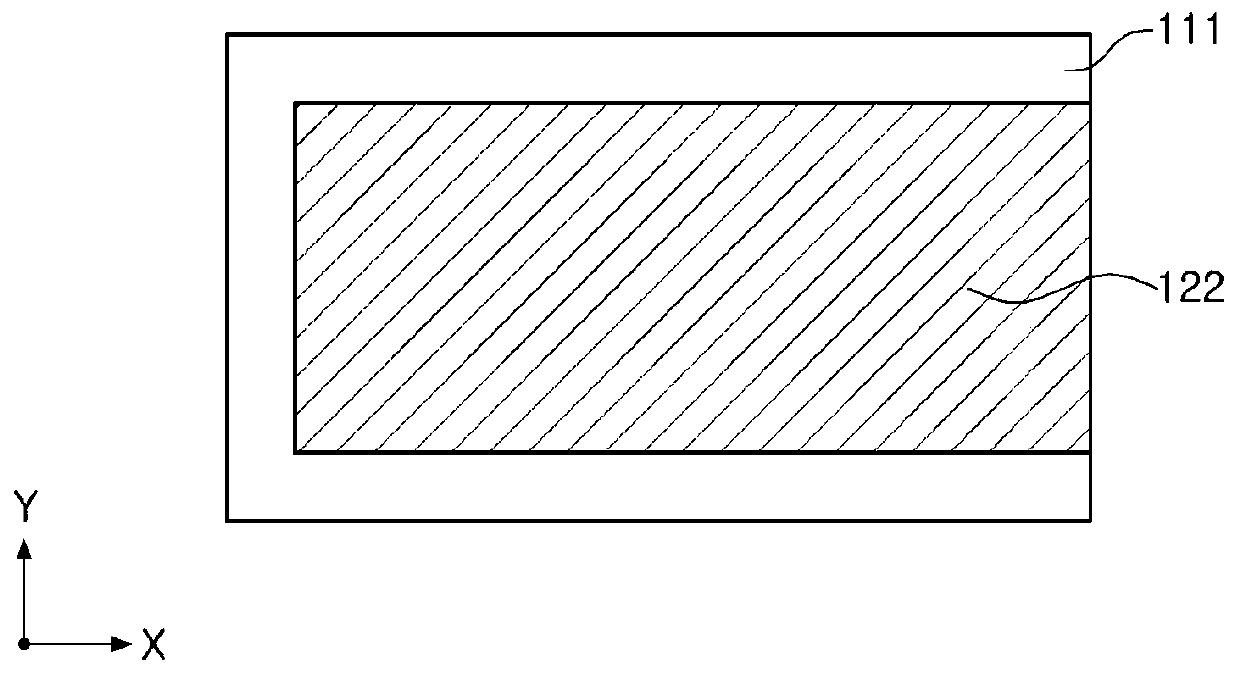

[0039] figure 1 is a perspective view schematically showing a multilayer capacitor applied to an exemplary embodiment in the present disclosure, Figure 2A with Figure 2B is shown applied to figure 1 A plan view of the first internal electrode and the second internal electrode of the multilayer capacitor, image 3 is along figure 1 The cross-sectional view taken along the line II'.

[0040] First, refer to Figure 1 to Figure 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com